Aluminaut facts for kids

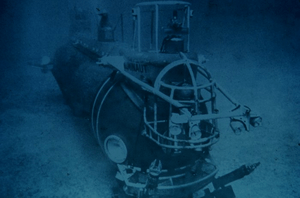

Aluminaut underwater in 1972 (NOAA/NURP)

|

|

Quick facts for kids History |

|

|---|---|

| Name | Aluminaut |

| Owner | Reynolds Metals Company |

| Operator | Reynolds Marine Services |

| Builder | General Dynamics Electric Boat, Groton, Connecticut, US |

| Launched | 1964 |

| In service | 1964 |

| Out of service | 1970 |

| Homeport | Miami, Florida, US |

| Status | Preserved as museum ship; Science Museum of Virginia; Richmond, Virginia, US |

| General characteristics | |

| Type | Deep-submergence vehicle (DSV) |

| Tonnage | 80 short tons (73 t) |

| Displacement | 80 short tons (73 t) |

| Length | 51 ft (16 m) |

| Beam | 8 ft 1 in (2.46 m) |

| Speed | 3 knots (5.6 km/h; 3.5 mph) |

| Endurance | 32 hours |

| Test depth | 17,000 feet (5,200 m) |

| Capacity | 6,000 lb (2,700 kg) payload |

| Crew | 6-7 (3 crew, 3-4 scientists) |

The Aluminaut was a special deep-sea submarine built in 1964. It was the world's first submarine made from aluminum. This experimental vessel weighed 80 tons and was designed for deep-ocean research.

Reynolds Metals Company built the Aluminaut. They wanted to show how strong and useful aluminum could be. The submarine was based in Miami, Florida. From 1964 to 1970, it was operated by Reynolds Submarine Services.

The Aluminaut worked for the U.S. Navy and other groups. It even helped famous marine biologist Jacques Cousteau.

This submarine is famous for two big missions. In 1966, it helped find a lost hydrogen bomb for the U.S. Navy. Then, in 1969, it rescued another deep-sea submarine, DSV Alvin. Alvin had sunk in the Atlantic Ocean the year before.

After its working years, the Aluminaut was given to the Science Museum of Virginia. You can see it on display there in Richmond, Virginia.

Contents

Building the World's First Aluminum Submarine

Reynolds Metals was a company that made many aluminum products. They created aluminum buses and other vehicles.

The idea for an aluminum submarine started during World War II in 1942. Julian "Louis" Reynolds, a leader at the company, thought of it. He wanted to use aluminum in new and exciting ways.

In 1964, Reynolds Metals hired General Dynamics Electric Boat to build the Aluminaut. This company was located in Groton, Connecticut. The new submarine was operated by a Reynolds company based in Miami, Florida.

The Aluminaut was quite large for a deep-sea vessel. It weighed 80 tons and could carry a crew of three. It also had space for three or four scientists. The submarine had four windows to look out of. It also had sonar to find things underwater and robotic arms to pick them up. It could carry up to 6,000 pounds (2,700 kg) of equipment.

The submarine was built to handle many different jobs. It could explore the ocean or help recover lost items. Its hull was made of 11 strong aluminum cylinders. Aluminum is lighter and stronger than steel for its weight. This allowed the Aluminaut's 6.5-inch-thick (170 mm) shell to withstand huge pressures. It could dive to a maximum depth of 17,000 ft (5,200 m).

The design for the Aluminaut came from the Woods Hole Oceanographic Institution. This institution is in Woods Hole, Massachusetts. At first, the project was top-secret. Early designs had some problems, but engineers kept working. They even built a small model in 1960 to test its strength.

1966: Finding a Lost Bomb

The Aluminaut soon proved its worth in a very important mission. On January 17, 1966, a U.S. Air Force plane crashed over Palomares, Spain. During the crash, a large bomb was lost in the Mediterranean Sea.

Three bombs fell on land and were quickly found. But one bomb, a powerful thermonuclear bomb, sank into the ocean. It was very hard to find.

The U.S. Navy sent a large team to the coast of Spain. This team included 18 ships and 2,200 people. The civilian-crewed Aluminaut and another deep-sea submarine, Alvin, joined the search. They worked together to find the lost bomb deep underwater.

The search lasted for eighty days. Finally, Alvin found the bomb resting about 910 metres (3,000 ft) below the surface. On April 7, 1966, the bomb was carefully brought to the surface. It was placed on the deck of the submarine rescue ship USS Petrel. News reporters were allowed to take pictures of it.

1969: Rescuing the Alvin Submarine

Both Aluminaut and Alvin started working in 1964. While Aluminaut retired, Alvin is still in service today. But in 1969, Aluminaut played a key role in saving Alvin.

In October 1968, Alvin was being moved by its support ship, the Lulu. As Alvin was being lowered into the water, two steel cables broke. Three crew members were inside Alvin with the hatch open. They managed to escape just as Alvin quickly sank. It ended up in 1,500 metres (4,900 ft) of water.

In September 1969, the Aluminaut was sent to help. It found Alvin almost a mile deep, still in one piece. Aluminaut then attached ropes and a net to the sunken submarine. Another ship, the USS Mizar, then pulled Alvin back to the surface.

When Alvin was opened, lunches left inside were found. They were soggy but still edible! This showed scientists that the cold, dark, and low-oxygen conditions deep underwater can preserve things. After this rescue, Alvin needed a lot of repairs.

Other Important Missions

The Aluminaut did other important jobs for the U.S. Navy. It recovered a 2,100-pound (950 kg) torpedo from a testing area in the Bahamas. It also helped make films for Jacques Cousteau and Ivan Tors Studios. The submarine explored depths up to 6,000 feet (1,800 m) for the U.S. Naval Oceanographic Office.

Retirement and Display

The Aluminaut stopped its active service in 1970. Reynolds Metals Company donated it to the Science Museum of Virginia. It is now on display at the Garner Pavilion in Richmond, Virginia. Even though it's a museum exhibit, the submarine is still kept in good condition. This means it could be used again if there was a special need.

See also

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |