Claymills Pumping Station facts for kids

Claymills Pumping Station is a historic building near Burton upon Trent, Staffordshire, England. It was built during the Victorian era to pump sewage (wastewater) away from the town. The station was designed by a famous engineer named James Mansergh. Its job was to send the sewage to a special farm in Egginton.

Contents

Giant Steam Engines at Claymills

The main part of Claymills Pumping Station has four huge steam engines. These are called 'Woolf compound rotative beam engines'. They were built in 1885 by a company called Gimson and Company from Leicester.

How the Engines Work

The engines are set up in two pairs, with a central building for the boilers and a tall chimney. Each engine has two main parts: a high-pressure cylinder and a low-pressure cylinder. These cylinders work together to move a giant metal beam. This beam is very long, about 26 feet, and weighs 13 tons! It helps to power the pumps.

Bringing the Engines Back to Life

All four of these big engines worked until 1969 and 1971. After that, they stopped running for many years. But volunteers started bringing them back to life! The first engine, 'D', started working again in 2001. Then 'C' in 2002, 'B' in 2017, and finally 'A' in 2023. Now, all four engines can be seen working about 14 weekends each year. The site actually has 33 original steam engines that can still run!

Restoring a Piece of History

After the pumping station closed in 1971, it started to fall apart. But in 1993, a group called the Claymills Pumping Engines Trust got access to the site. Since then, many dedicated volunteers have worked hard to restore it. Thanks to their skills and commitment, the station is in great condition today.

Saving the Smaller Engines

When the site closed, the chief engineer at the time worked hard to save many of the smaller steam engines. He sent them to other museums to keep them safe. Because of his efforts, the Trust has been able to get most of these engines back.

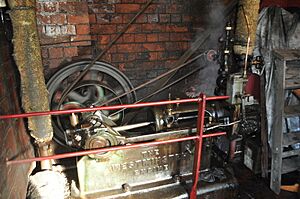

The Dynamo House: Making Electricity

The pumping station also has a special building called the Dynamo House. Here, two steam-powered machines called dynamos make electricity. One dynamo was built in 1889 and is quite large. The other, smaller one was made at Claymills in 1906. Both of these dynamos can still run today.

Powering the Site

These dynamos were very important. They provided all the electricity for the lights at the pumping station and for the homes of the workers nearby. The larger dynamo was used at night, and the smaller one during the day. They supplied power until 1971. The engine that drives the smaller dynamo is thought to have been built right there in the Claymills workshop!

The Workshop: A Place for Repairs

In 1900, a large workshop was added to the Claymills site. This workshop was used by the local council until 1971. When it closed, all the machinery was removed. However, the Trust has managed to get most of the original machines back. Now, the workshop is fully restored and can be used again.

The Boiler House: Where Steam is Made

Steam for all the engines at Claymills is made in five large Lancashire boilers. The first boilers were made by Robert Stephenson and co. Usually, only two of the five boilers would be working at any time. The others would be ready as a backup or undergoing maintenance.

Boiler Upgrades and Fuel

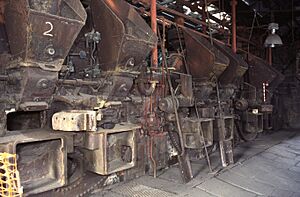

The original boilers were made of wrought iron. In 1936, they were replaced with new steel ones by John Thomson and co. This was done one boiler at a time so the station could keep working. The boilers use coal as fuel. At first, people had to shovel coal by hand. But later, mechanical stokers were installed in 1908 and then improved around 1920. These mechanical stokers are still used today when the Trust runs the engines. The Trust has also been trying out using Biomass as a fuel.

See also

- Listed buildings in Burton (civil parish)