Forth Bridge facts for kids

Quick facts for kids Forth Bridge |

|

|---|---|

|

Forth Bridge in July 2022

|

|

| Coordinates | 56°00′01″N 3°23′19″W / 56.0004°N 3.3886°W |

| Carries | Rail traffic |

| Crosses | Firth of Forth |

| Locale | Edinburgh, Inchgarvie and Fife, Scotland |

| Owner | Network Rail |

| Maintained by | Balfour Beatty under contract to Network Rail |

| Characteristics | |

| Design | Cantilever bridge |

| Total length | 8,094 feet (2,467 m) |

| Width | 120 ft (37 m) at piers 32 ft (9.8 m) at centre |

| Height | 361 ft (110 m) above high water |

| Longest span | Two of 1,700 feet (520 m) |

| Clearance below | 150 ft (46 m) to high water |

| History | |

| Designer | Sir John Fowler and Sir Benjamin Baker |

| Construction begin | 1882 |

| Construction end | December 1889 |

| Opened | 4 March 1890 |

| Statistics | |

| Daily traffic | 190–200 trains per day |

| Official name: The Forth Bridge | |

| Type: | Cultural |

| Criteria: | i, iv |

| Designated: | 5 July 2015 |

| Reference #: | 1485 |

|

Listed Building – Category A

|

|

| Official name: Forth Bridge | |

| Designated: | 18 June 1973 |

| Reference #: | LB40370 |

The Forth Bridge is a famous cantilever railway bridge in the east of Scotland. It crosses the Firth of Forth, a large sea inlet, about 9 miles west of central Edinburgh. Completed in 1890, this amazing bridge is a true symbol of Scotland. In 2016, it was even voted Scotland's greatest man-made wonder. The Forth Bridge is also a special UNESCO World Heritage Site. It was designed by two brilliant English engineers, Sir John Fowler and Sir Benjamin Baker. Sometimes, people call it the Forth Rail Bridge to tell it apart from the nearby road bridges, but its official name is simply the Forth Bridge.

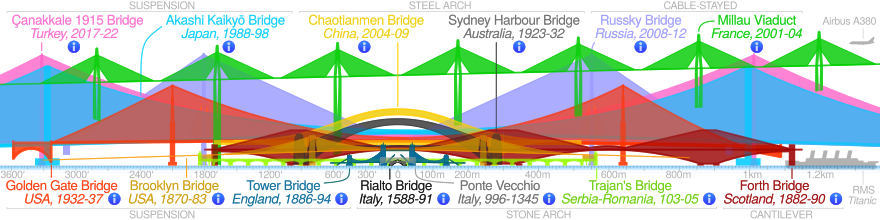

Construction of this massive bridge started in 1882. It officially opened on March 4, 1890, with the Duke of Rothesay, who later became Edward VII, doing the honors. The bridge carries the Edinburgh–Aberdeen line for trains between the villages of South Queensferry and North Queensferry. It has a total length of 2,467 metres (8,094 ft). When it first opened, it had the longest single cantilever bridge span in the world. This record was held until 1919, when the Quebec Bridge in Canada was completed. Today, it remains the world's second-longest single cantilever span, with two spans each measuring 1,709 feet (521 m).

The bridge and its railway tracks are currently owned by Network Rail.

Contents

The Amazing Forth Bridge

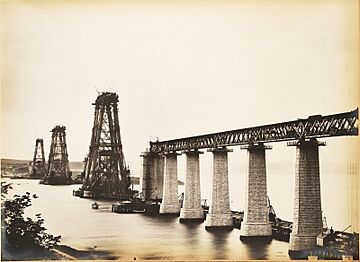

Building a Scottish Icon

Early Ideas for Crossing the Forth

Before the Forth Bridge was built, people used ferries to cross the Firth of Forth. Imagine trying to get across a wide river without a bridge! In the early 1800s, engineers suggested different ideas. One idea in 1806 was to build two tunnels under the water. Later, in 1818, James Anderson designed a suspension bridge with three spans. It would have used about 2,500 tonnes (2,500 long tons; 2,800 short tons) of iron. People thought it would look so light that it might disappear on a cloudy day!

For trains, Thomas Bouch designed a special ferry that allowed trains to roll on and off. This ferry service, which started in 1850, was very successful. Because of this success, there was a growing interest in building a permanent bridge for trains.

Learning from Past Bridge Challenges

Building a bridge strong enough for trains was a huge challenge. Another engineer, Thomas Bouch, tried to design a bridge for the Forth in the 1860s. However, there were concerns about how to build strong foundations in the soft, silty riverbed. Experiments showed it might be possible, but the project faced financial problems and was stopped.

Later, in 1871, Bouch proposed a different design for a steel suspension bridge. Work even began on a pier for this design. However, a terrible event changed everything. In 1879, another bridge designed by Bouch, the Tay Bridge, collapsed during a strong storm. This disaster showed that bridges needed to be much stronger to withstand high winds.

After the Tay Bridge collapse, engineers realized that Bouch's Forth Bridge design wasn't strong enough for the new safety rules. These rules required bridges to handle very strong winds. So, Bouch's design was cancelled in 1881. New engineers, Sir John Fowler, W. H. Barlow, and T. E. Harrison, were asked to create a completely new and safer design.

How the Forth Bridge Was Designed

Key Features and Size

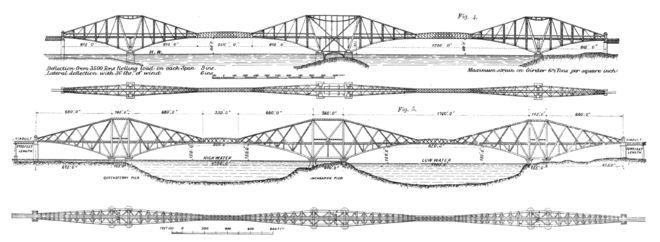

The Forth Bridge connects South Queensferry and North Queensferry. It stretches for 2,467 metres (8,094 ft) and its railway tracks are 150 feet (45.72 m) above the water at high tide. The bridge has two main spans, each 1,700 feet (518.16 m) long. It also has two side spans and 15 smaller approach spans. Each main span uses two 680 ft (207.3 m) cantilever arms. These arms support a central 350 feet (106.7 m) span truss. The entire steel structure of the bridge weighs 50,513 long tons (51,324 t). It holds 6.5 million rivets and used 640,000 cubic feet (18,122 m3) of granite.

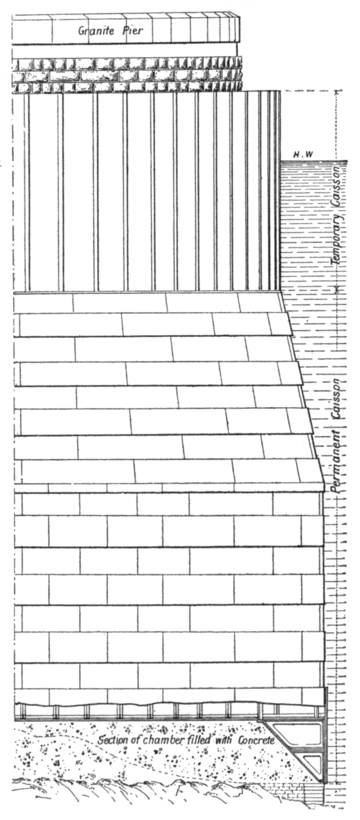

The bridge has three huge cantilever structures, each with four towers. These towers are 361 feet (110.03 m) tall. Each tower rests on its own granite pier. These piers were built using large, 70 ft (21 m) wide caissons. Some caissons acted like cofferdams, keeping water out. Others, especially where the riverbed was 91 ft (28 m) deep, used compressed air to create dry working spaces underwater.

Understanding Cantilever Design

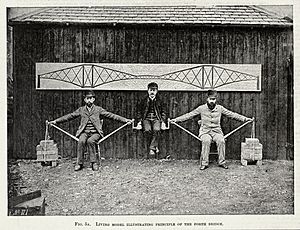

The Forth Bridge uses the cantilever bridge principle. This design has been used for thousands of years. A cantilever beam is like a diving board that sticks out from a support. In the Forth Bridge, strong cantilever arms support a lighter central section. To show how this works, engineers once used a fun demonstration. The Japanese engineer Kaichi Watanabe sat between Sir John Fowler and Sir Benjamin Baker, who were sitting in chairs. Fowler and Baker represented the cantilevers, showing how different parts of the bridge are either stretched (in tension) or squeezed (in compression).

Strong Materials: Steel for the Future

The Forth Bridge was the first major structure in Britain to be built using steel. At the same time, the Eiffel Tower in France was being built with wrought iron. Steel became widely available after the invention of the Bessemer process in 1856. This new, strong material was perfect for a bridge that needed to withstand powerful forces.

The bridge used 55,000 tonnes (54,000 long tons; 61,000 short tons) of steel. Most of this steel came from works in Wales and Scotland. About 4,200 tonnes (4,100 long tons; 4,600 short tons) of rivets, which are like strong metal pins, came from Glasgow.

Designing the Approach Viaducts

The railway tracks leading up to the main bridge are called approach viaducts. These were designed by engineer James Carswell. The supports for these viaducts are shaped in a special way, tapering as they go up. This design makes them look elegant and strong. Experts who studied the bridge's look in 2007 noted how carefully planned the masonry was, even in places not easily seen.

Constructing a Giant: The Building Process

The plan to build the Forth Bridge was approved on May 19, 1882. The main construction contract was given to Sir Thomas Tancred, T. H. Falkiner, Joseph Philips, and Sir William Arrol & Co.. Sir William Arrol was a remarkable person who started as a blacksmith at 13 and built a very successful business. The steel for the bridge was produced by companies in England and France, using new furnace designs to create high-quality steel quickly.

Preparing the Construction Sites

Building such a huge bridge required massive preparations. Offices and stores were set up and expanded. Engineers carefully surveyed the area to find the exact spot for the bridge. At the Fife end, the rocky shore was leveled, and huts for workers were built.

The preparations at South Queensferry were even bigger. The steep hillside was terraced, and many wooden huts and workshops were built for the workers. There were also brick houses for foremen. A large drawing loft, 200 by 60 feet (61 by 18 m), was created to lay out full-size drawings and templates. A telephone cable was even laid across the Forth to connect the different construction sites. A long jetty, about 2,100 feet (640 m), was built to bring in materials.

On the island of Inchgarvie, existing buildings were used, and the rock was cut down. Iron staging was put up, eventually covering about 10,000 square yards (8,400 m2) of the island.

Moving Materials and Workers

The bridge used 55,000 tonnes (54,000 long tons; 61,000 short tons) of steel and 140,000 cubic yards (110,000 m3) of masonry. Materials like granite from Aberdeen, sand, and timber were brought directly to where they were needed. Steel was delivered by train, prepared at South Queensferry, and then moved by barge. The Portland cement used was stored in a large barge called the Hougoumont.

Moving thousands of workers was also a big task. A paddle steamer was hired, and later replaced by a larger one that could carry 450 men. Special trains ran from Edinburgh and Dunfermline, and a steamer went to Leith in the summer.

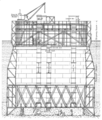

Building the Underwater Foundations

The three main towers of the bridge each sit on four circular piers. Since these foundations were mostly underwater, engineers used special structures called caissons and cofferdams. Caissons were used for deep underwater locations or where the ground was soft mud and clay. Cofferdams were used where rock was closer to the surface, allowing work at low tide.

Six caissons were built using a special pneumatic process. This method used positive air pressure inside a sealed caisson to keep water out, allowing workers to build in dry conditions up to 89 feet (27 m) deep. These huge caissons were built in Glasgow, then taken apart, moved to South Queensferry, and reassembled. They were then floated to their final spots and sunk into place. The first caisson was launched on May 26, 1884, and the last on May 29, 1885. Once in place, they were extended upwards to allow the granite piers to be built.

Each granite pier is 36 feet (11 m) tall and 55 feet (17 m) wide at the bottom.

Raising the Approach Viaducts

The approach viaducts, which lead to the main bridge, needed to be 130 feet 6 inches (39.78 m) above high water. Engineers built them at a lower level and then slowly raised them as the masonry piers were constructed. There are fifteen spans in total, each 168 feet (51 m) long and weighing over 200 tonnes (200 long tons; 220 short tons). Large hydraulic rams lifted these sections about 3 feet 6 inches (1.07 m) every four days.

Assembling the Cantilever Towers

The large tubular parts of the bridge were made in workshops at South Queensferry. Steel plates were heated and bent into the correct curved shapes. These curved plates were then put together, and holes were drilled for the millions of rivets. Each part was carefully marked and moved to its exact place on the bridge structure. Cranes and powerful hydraulic rivetters helped assemble these massive pieces.

The Grand Opening Day

The Forth Bridge was finished in December 1889. To make sure it was safe, engineers performed load testing on January 21, 1890. Two trains, each with three heavy locomotives and 50 wagons full of coal (a total of 1,880 tons!), slowly crossed the bridge. This weight was more than double what the bridge was designed to carry. The bridge performed perfectly, showing only a small bend, just as expected.

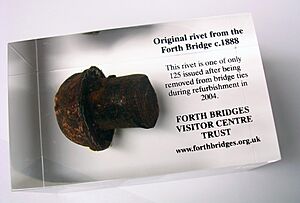

The first complete train crossing happened on February 24, 1890. The official opening was on March 4, 1890, by the Duke of Rothesay, who later became King Edward VII. He famously drove in the very last rivet, which was gold-plated and specially engraved. When it opened, the Forth Bridge had the longest single cantilever bridge span in the world. This record was held until 1919 when the Quebec Bridge in Canada was completed. Today, it remains the world's second-longest single cantilever span.

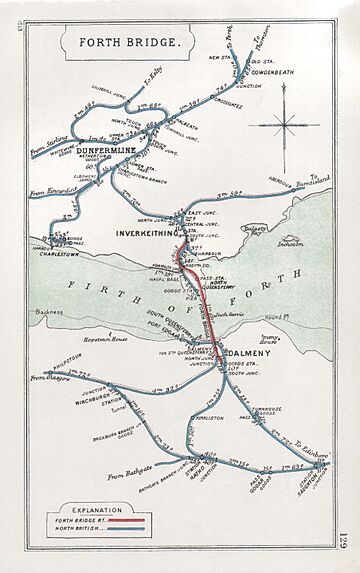

To make the most of the new bridge, several new railway lines were built to connect to it. This allowed for faster and more direct train services.

Remembering the Workers: Safety and Sacrifice

Building the Forth Bridge was an incredibly difficult and dangerous job. At its busiest, about 4,600 workers were involved in its construction. Sadly, many workers lost their lives during this huge project. Records from 1890 show that 57 people died. However, historians have since found that at least 78 deaths were connected to the bridge's construction.

To help the workers and their families, a "Sick and Accident Club" was created in 1883. All employees had to join. This club provided medical care, paid workers if they couldn't work, and helped with funeral costs. It also gave money to the widows of men who died or the wives of those permanently disabled. There is now a memorial to honor all the brave workers who lost their lives building this magnificent bridge.

The Forth Bridge Through History

The "Race to the North"

Before the Forth Bridge, train journeys from London to Aberdeen took about 13 hours. With the new bridge, railway companies on the east coast route could offer much faster journeys. This led to an exciting "Race to the North" in the 1890s. Rival railway companies competed to see who could get passengers from London to Scotland the fastest. This unofficial race made daily headlines and cut journey times significantly.

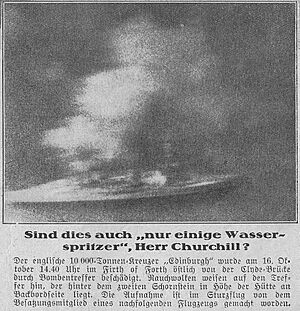

The Bridge During Wartime

During the First World War, British sailors used the bridge as a landmark when leaving or returning to the naval base at Rosyth. In the Second World War, the area around the Forth Bridge was the site of the first German air attack on Britain. This happened on October 16, 1939, just six weeks into the war. Although the event is known as the "Forth Bridge Raid," the bridge itself was not the target and was not damaged. The German bombers were aiming for naval ships at the Rosyth Dockyard, about 2 miles (3.2 km) west of the bridge. British Spitfire planes intercepted the attackers, shooting down the first German aircraft over Britain in the war.

Who Owns and Cares for the Bridge?

The Forth Bridge was a joint project. The North British Railway (NBR) wanted a direct link to Fife, independent of rival companies. Three English railway companies also contributed to the cost, as they ran trains from London over NBR tracks. A committee was set up in 1881 to build and maintain the bridge.

After the 1923 Grouping of railway companies, the bridge became jointly owned by the London Midland and Scottish Railway and the London and North Eastern Railway. In 1948, when British railways were nationalized, the Forth Bridge became part of British Railways. As of April 2017, the bridge and its railway infrastructure are owned by Network Rail Infrastructure Limited.

Keeping the Bridge Running

Daily Train Traffic

The Forth Bridge is a busy railway line. High-speed trains and diesel trains can travel up to 50 miles per hour (80 km/h) across it. Regular passenger trains have a limit of 40 miles per hour (64 km/h), and freight trains travel at 30 miles per hour (48 km/h). In 2006, between 190 and 200 trains crossed the bridge every day!

The Never-Ending Task of Maintenance

You might have heard the saying "Painting the Forth Bridge" to describe a task that never ends. This saying came from the mistaken belief that as soon as the bridge was painted, workers had to start all over again. While this wasn't exactly true, the bridge did require constant maintenance. There was always a permanent crew of painters.

However, between 2001 and 2011, the bridge received a brand new, super-durable coating. This special paint was designed to last for 25 years. This meant that for the first time in its history, a regular team of painters was no longer needed on the bridge!

Modern Restoration Efforts

In 1990, special floodlights were installed to light up the bridge at night. The railway tracks were also replaced between 1992 and 1995. Maintaining the bridge was very expensive, costing British Rail £1 million a year.

In 2002, a massive £130 million project began to fully repaint the bridge. This was the first time in its history that every part of the bridge was repainted. Up to 4,000 tonnes (3,900 long tons; 4,400 short tons) of scaffolding was used, and computer models helped engineers understand how the extra weight and wind would affect the structure. The bridge was even covered in a special climate-controlled membrane to ensure the paint was applied perfectly. All the old layers of paint were removed using high-pressure copper slag. A new, very durable paint system, similar to what's used on North Sea oil rigs, was applied. This new paint is expected to last for at least 20 years, greatly reducing future maintenance work.

In 2007, a report estimated that the Forth Bridge could last for more than 100 additional years. This depends on Network Rail continuing its regular inspection and refurbishment work.

The Forth Bridge in Popular Culture

Featured in Movies and Books

The Forth Bridge has appeared in many movies and TV shows. You can spot it in films like Alfred Hitchcock's 1935 movie The 39 Steps and its 1959 remake. The Scottish soft drink Irn-Bru famously used the bridge in its advertisements with the slogan: "Made in Scotland, from girders." In 2005, the BBC lit the bridge in red for Comic Relief. A French freerunner, Sébastien Foucan, was even shown crawling along one of the highest points of the bridge without a harness in a documentary!

A Symbol of Engineering and Scotland

The Forth Bridge has inspired many creative works. For the Millennium celebrations, a countdown clock sponsored by the Royal Bank of Scotland was placed on top of the bridge in 1998. Author Iain Banks set his novel The Bridge on a fictional version of this famous structure. Even in Alan Turing's famous paper about artificial intelligence, he challenged a computer to write a sonnet about the Forth Bridge! The bridge also appears in the video game Grand Theft Auto: San Andreas, renamed as the Kincaid Bridge.

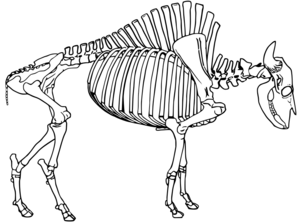

The mathematical biologist D'Arcy Thompson even compared the bridge's structure to the skeleton of an ox in his 1917 book On Growth and Form. He saw the piers as legs and the cantilevers as the backbone!

The Forth Bridge was recognized as a UNESCO World Heritage Site on July 5, 2015. UNESCO called it "an extraordinary and impressive milestone in bridge design and construction." It was the sixth World Heritage Site in Scotland. In 2016, a survey by VisitScotland voted the Forth Bridge "Scotland's greatest man-made wonder."

The Forth Bridge has also been featured on money! It appeared on a 2004 one pound coin. It's also on banknotes, including the 2007 series from the Bank of Scotland and a special £5 polymer banknote issued by Clydesdale Bank in 2015. This £5 note celebrated the bridge's 125th anniversary and its nomination as a World Heritage Site.

Visiting This Historic Landmark

Network Rail had plans to add a visitor center to the bridge. These plans included a viewing platform on the North Queensferry side or a bridge climbing experience on the South Queensferry side. In December 2014, Arup was awarded the design contract for this project. In September 2019, Network Rail submitted plans for a visitor center at South Queensferry, which would be the base for a "Forth Bridge Experience" where people could climb the bridge. These plans were approved in early 2020 but were put on hold due to the COVID-19 pandemic. Revised plans were submitted in February 2022.

Images for kids

-

Close up on the base of one of the three double-cantilevers of the bridge

See also

In Spanish: Puente de Forth para niños

In Spanish: Puente de Forth para niños

| Stephanie Wilson |

| Charles Bolden |

| Ronald McNair |

| Frederick D. Gregory |