Japanese kitchen knife facts for kids

A Japanese kitchen knife is a special kind of knife used for preparing food. These knives come in many different shapes and sizes. They are often made using old Japanese sword-making techniques. This means they are crafted with great care and skill.

Japanese knives can be made from stainless steel, which resists rust, or from a special steel called hagane. This hagane is the same strong steel used to make traditional Japanese swords. Most of these knives are called hōchō (包丁/庖丁). Sometimes, if the name is part of a longer word, it changes to -bōchō. Other knives might have names like -kiri (〜切り), which means "cutter."

Japanese knives are usually grouped into four main types. These types depend on their handle (Western or Japanese), how the blade is sharpened (one side or both sides), the kind of steel used (stainless or carbon), and how they are built (layers or one solid piece).

Contents

Knife Handles: Western vs. Japanese Styles

The handle of a knife is very important for how it feels to use. Japanese kitchen knives come with two main types of handles: Western and Japanese.

Western Knife Handles

Western-style handles usually have a bolster, which is a thick part where the blade meets the handle. They also have a full or partial tang. The tang is the part of the blade that extends into the handle. These handles are often heavier. However, they are usually smaller and smoother than Japanese handles. They are often made from strong plastic or wood treated with resin. This makes them non-porous, meaning they don't soak up liquids. Chefs who like Western handles often prefer a knife that feels heavier in the handle. They also tend to grip the handle closer to the blade. This extra weight helps them make powerful cuts.

Japanese Knife Handles

Japanese-style handles are often made from ho wood. This wood is usually heated and then fitted onto a hidden tang. A buffalo horn piece often covers the spot where the handle meets the blade. This helps prevent the wood from splitting. These handles are easy to put on and replace. Ho wood is light and has a fine grain. This makes it less likely to crack and helps you keep a good grip.

Sometimes, more fancy woods like ebony, yew, cherry, or chestnut are used for handles. These are heavier and sometimes burned on the outside to make them easier to grip and more water-resistant. If these decorative woods are not cared for well, they can crack easily when they get wet. Another material called Pakka wood is also used. It's a layered wood often found on less expensive knives. It's waterproof because it's held together with a special resin. Chestnut wood is a very common type of wood used for these handles.

The most common shape for a Japanese handle is an octagon. It usually gets a little thinner towards the blade. Another popular shape is the "D" shape. This is an oval handle with a small ridge on the same side as the blade's sharp edge. This ridge helps right-handed users grip the knife better. Chefs who want a lighter knife overall, or one that feels lighter in the handle, often choose Japanese handles. They also like that these handles are larger and easier to replace.

Knife Blades: Different Shapes and Uses

The blade is the cutting part of the knife. Japanese knives have many different blade designs, each made for specific tasks.

Double Bevel Blades

Traditional Western knives have a double bevel. This means the blade tapers, or gets thinner, evenly on both sides down to the cutting edge. Japan started using ideas from French and German knives during the Meiji period in the late 1800s. They mixed these ideas with their own cutting styles. Japanese knives are often flatter than European ones.

Here are some common double bevel knives:

- katsuobushi-kiri (鰹節 切): This knife is used to slice very thin pieces of dried bonito fish, called katsuobushi. These thin slices are used in many Japanese dishes. The blade is short, about 65mm long, and looks a bit like a wood carving knife.

- Gyuto (牛刀): This knife is like the chef's knife used in Western cooking. It's very versatile. You can use it for chopping vegetables near the handle. You can also use it to rock-chop tough foods or make fine cuts with the tip. It's great for many kinds of meat. For large pieces, you can saw back and forth. For softer meats, you pull the knife to cut. For tougher meats, you push it. The blade usually slopes down from the handle to the tip. This can make your wrist point down and your shoulder rise when cutting. Gyuto blades are usually 210mm to 270mm long. Shorter blades are easier to move, longer blades cut more powerfully, and middle sizes are good for general use.

- Santoku (三德): This name means "three virtues." The santoku, also called bunka bocho (culture knife), is a multi-purpose knife. It's mainly used for vegetables and fish. These knives are generally flatter than gyuto knives and have a less pointy tip. Because they are flatter, your wrist stays in a more natural position, and you don't need to raise your shoulder as high. These knives don't need as much space to cut. They are the most popular knives in many Japanese homes. Their size usually ranges from 165mm to 180mm.

- Nakiri (菜切): This knife means "vegetable cutter." Its square tip makes it feel strong and secure. This helps it cut through thick foods at the tip. This knife has a flat edge. Some nakiri knives have a blade that tilts slightly towards the handle. This makes the grip more comfortable. It lets you use strength from your forearm when cutting. Their size usually ranges from 165mm to 180mm.

- Petty: This is a smaller knife often used with the gyuto. It's good for peeling fruits or cutting smaller vegetables. Sizes range from 120mm to 180mm.

- Sujihiki (筋引): This means "muscle cutter." These are long knives used to slice meat, often with a pulling motion. Sizes range from 240mm to 300mm.

- Hankotsu: This is a butchering knife used to cut meat off bones, especially from hanging cattle. It's usually about 150mm long.

- Chukabocho: Also known as the Chinese chef knife, the chukabocho has a short handle, a flat profile, and a tall blade. This tall blade helps you get more power when cutting. The blade is usually thicker behind the edge to cut through tougher ingredients and sometimes even bone.

Single Bevel Blades

Single bevel knives are traditional Japanese knives. They are sharpened on only one side. They have an omote (the main cutting edge, usually on the right for right-handers). They also have a shinogi, which is where the front sharpened part meets the flat part of the blade. The urasuki is a hollow area on the back side of the blade. This hollow helps food fall away easily after you cut it.

These knives are usually a bit thicker at the top and body than double bevel knives. However, they are very thin right behind the cutting edge. While they make a very smooth cut, the food might need to bend more because the blade is thicker. These knives are key to traditional Washoku (Japanese cuisine). They were first developed from Chinese double bevel knives.

To sharpen them, you press on both the shinogi and the edge. Honbazuke is the first sharpening. It creates a flat surface around the hollow back (urasuki), making it stronger and setting its shape for future sharpening. The omote side is sharpened much more than the urasuki side to keep the single bevel working correctly.

Kansai style knives usually have a pointed tip for cuts that go straight down. This is good for fancy tip work. Edo style knives have a square tip for horizontal cuts, making them stronger for everyday use. The main traditional Japanese knife set includes the yanagiba, deba, and usuba.

Here are some common single bevel knives:

- Yanagiba: This means "willow blade." It's the most popular knife for cutting fish, also known as shobu-bocho (sashimi knife). It's used to show off different textures of fish. For example, hirazukuri is a vertical pull cut, usuzukuri is a thin vertical pull cut, and sogizukuri is a pull cut at an angle. It's also used to skin and sometimes de-bone certain fish like salmon. Yanagiba knives have angled tips and are generally heavier with less slope. A regional type called takohiki (octopus cutter) is lighter, thinner, flatter, and shorter than a yanagiba. This makes it easier to cut through tough octopus meat. These knives are usually 270mm to 330mm long.

- Deba: These are thick knives used to cut through tough fish flesh for filleting. They can also cut through rib bones, behind the head, and through the head of a fish. They are 5mm to 9mm thick, depending on their size. Types include hon-deba (true deba), ko-deba (small deba), ajikiri (for aji fish), funayuki (a smaller, more pointed knife for use on boats), and mioroshi deba (a mix between deba and yanagiba, with medium thickness, weight, and length). Smaller deba knives are thinner and more agile, allowing them to move through flesh easily. However, they are still thinner behind the edge and more delicate than Western butcher knives. Their size usually ranges from 120mm to 210mm.

- Usuba: This means "thin blade." It's the thinnest of the three main traditional knife shapes and has a flat edge. It's used for push cutting, katsuramuki (making thin sheets by rotary cutting), and sengiri (cutting thin strips from those sheets). There are two main types: edo-usuba (with a square tip) and kamagata-usuba (with a round tip). Their sizes usually range from 180mm to 240mm.

- Kiritsuke: This is a hybrid knife. It has the length of a yanagiba and the blade height and profile of an usuba, but with an angled tip. It requires great knife control because it's tall, long, and flat. Sizes usually range from 240mm to 300mm.

- Mukimono: Used with the usuba for vegetables. It has an angled tip for decorative vegetable cutting. Sizes usually range from 150mm to 210mm.

- Hamokiri: This means "pike conger cutter." It's a knife with medium thickness and length, between a deba and a yanagiba. It's used to cut the thin bones and flesh of pike conger fish. Sizes usually range from 240mm to 300mm.

- Magurokiri: This means "tuna knife." It's used to cut tuna. It can be shorter for cutting across the tuna or longer and more flexible for cutting along it. Sizes range from 400mm to a very long 1500mm.

- Honesuki: Used to debone chicken. A thicker version called garasuki is used to cut through bones. Most have an angled tip to slip between tendons and cut them. Sizes usually range from 135mm to 180mm.

- Sobakiri: This means "soba cutter." A similar knife is the udonkiri (udon cutter). Sizes usually range from 210mm to 300mm.

- Unagisaki: This is an eel knife. It comes in different versions from various regions like Kanto, Kyoto, Nagoya, and Kyushu.

- Mochikiri: This means "mochi cutter." It's used to prepare mochi (Japanese rice cakes). It can have one or two handles.

Steel: The Heart of the Blade

The type of steel used is very important for a Japanese kitchen knife. It affects how tough the knife is (how well it resists breaking), how sharp it can get, how long it stays sharp, and how easy it is to sharpen. Even with the same steel, how it's heated and processed can change its qualities.

Stainless Steel

Stainless steel knives are generally tougher and less likely to chip than carbon steel knives. They are also less sharp. However, the very best stainless steels can stay sharp for a long time. Types of stainless steel include:

- Powdered steel: This steel has large particles that are broken up into powder. Then, they are pressed and heated together.

- Semi-stainless steel: This steel has less chromium, which helps prevent rust. It has qualities that are in between carbon steel and full stainless steel.

- Tool steel: This steel has many different metals mixed in. It may or may not be stainless.

Carbon Steel

Carbon steel knives are generally sharper, harder, and more brittle. This means they can chip more easily. They also rust more easily if not cared for. Types of carbon steel include:

- White steel: This steel is very pure, with very few impurities like phosphorus and sulfur. It's not mixed with other metals. It comes in different grades (1, 2, and 3), with grade 1 having the most carbon.

- Blue steel: This steel is pure and mixed with chromium and tungsten. These metals help the knife stay sharp longer and make it tougher. It comes in grades 1 and 2.

- Super blue steel: This is blue steel mixed with molybdenum and vanadium, plus more carbon. It stays sharp even longer but is a bit more brittle.

Construction: How Knives Are Built

The way a knife is built affects its strength and how it performs.

Monosteel Blades

Monosteel blades are made from a single piece of steel. They are usually harder to sharpen and thinner than laminated blades. There are three main types of monosteel blades:

- Zenko: These blades are simply stamped out from a sheet of steel.

- Honyaki: These are forged from carbon steel and then hardened differently across the blade. This makes the edge very hard and the spine (back) softer.

- Forged from a billet: These are forged from a block of steel without the special differential hardening.

Laminated Blades

Laminated blades are made from two or more pieces of steel joined together. They come in three main types: awase (meaning mixed), kasumi (meaning misty, because the iron looks misty after sharpening), and hon-kasumi (a higher quality kasumi).

To make a laminated blade, two pieces of steel are used: the jigane and the hagane. The jigane is the soft outer layer, or "skin." The hagane is the hard steel used for the cutting edge. Both can be carbon or stainless steel. This mix of metals makes laminated blades resistant to rust (with stainless steel) and strong (with high carbon steel). It's less common to see stainless steel on the outside with a carbon steel core because it's harder to make.

The jigane (soft outer layer) helps the knife be sharpened more easily and absorb shock. It also makes the hagane (hard cutting steel) even harder without making the whole blade fragile.

There are two main ways laminated blades are made:

- Ni-mai: This means two layers, with jigane covering the hagane.

- San-mai: This means three layers, with the hagane sandwiched between two layers of jigane.

Sometimes, special patterns are created in the jigane layer. These artistic patterns include:

- Suminagashi

- Damascus

- Kitaeji

- Mokume-gane

- Watetsu

Production: Where Japanese Knives Come From

Many high-quality Japanese knives come from Sakai. This city was a major center for samurai sword manufacturing since the 1300s. After the Meiji Restoration in 1868, samurai were not allowed to carry swords. So, many sword-makers started using their skills to make kitchen knives instead.

Knife making in Sakai began in the 1500s. That's when tobacco came to Japan, and Sakai craftsmen started making knives to cut tobacco leaves. The Sakai knife industry got a big boost from the Tokugawa shogunate (1603–1868). They gave Sakai a special seal of approval, which made its knives famous for their quality.

Today, Seki, Gifu is known as the home of modern Japanese kitchen knives. Here, advanced manufacturing technology is combined with old forging skills. This creates world-class stainless and laminated steel kitchen knives. Many big knife-making companies are in Seki. They make top-quality knives in both traditional Japanese and Western styles, like the gyuto and santoku.

Knives and swords are so important to Seki that the city has the Seki Cutlery Association, the Seki Swordsmith Museum, and hosts events like the Seki Outdoor Knife Show and the October Cutlery Festival. Most knife makers are small family businesses. They focus more on craftsmanship than on making many knives. They often produce fewer than a dozen knives each day.

Design and Use: How Japanese Knives Are Different

Japanese knives have unique designs that make them special.

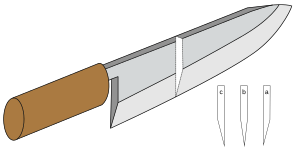

Unlike Western knives, Japanese knives are often "single ground." This means they are sharpened so that only one side forms the cutting edge. As you can see in the image, some Japanese knives are angled on both sides, but many are angled only on one side, with the other side of the blade being flat. People traditionally believed that a single-angled blade cuts better and makes cleaner cuts. However, it takes more skill to use than a knife sharpened on both sides. Usually, the right side of the blade is angled, because most people use their right hand to cut. Left-handed versions are rare and usually need to be specially ordered.

After World War II, Western-style knives, which are sharpened on both sides, became more popular in Japan. The santoku knife is an example of this change. It's an adaptation of the gyoto knife. Other knives that are now widely used in Japan include the French chef's knife and the sujihiki, which is similar to a Western carving knife. Even though these knives are usually sharpened evenly on both sides, their blades still have very sharp Japanese-style cutting edges (8-10 degrees per side). They are also made with very hard steel to improve their cutting ability.

Most professional Japanese cooks have their own set of knives. After using a carbon-steel knife, they might sharpen it in the evening. Then, they might let the knife "rest" for a day. This helps restore its natural protective layer and removes any metallic smell or taste that could get on the food. Some cooks even have two sets of knives for this reason.

Japanese knives have special features on their sharpened edges. Usually, the back side of the blade (the left side for a right-handed user) is curved inward. This curved part is called urasuki. It helps reduce friction and keeps food from sticking to the blade, so the food separates cleanly. The kanisaki deba, which is used for cutting crab and other shellfish, has its sharpened side on the opposite side (left side angled for right-handed use). This is so that the knife doesn't cut the meat when you are chopping the shell.

Images for kids

See also

In Spanish: Cuchillo de cocina japonés para niños

In Spanish: Cuchillo de cocina japonés para niños

| Bayard Rustin |

| Jeannette Carter |

| Jeremiah A. Brown |