Meat-packing industry facts for kids

The meat-packing industry is all about handling meat from farm animals like cattle, pigs, and sheep. This includes slaughtering (preparing animals for meat), processing (turning them into cuts of meat), packaging, and distributing the meat. While the main goal is to produce meat for people to eat, the industry also creates many useful by-products like animal skins, dried blood, and fats.

In places like the United States, a facility where meat packing happens is often called a slaughterhouse, packinghouse, or meat-packing plant. In New Zealand, they call it a freezing works because much of their meat is exported (sent to other countries).

The meat-packing industry grew a lot thanks to the invention of railroads and new ways to keep meat fresh using refrigeration. Railroads made it possible to transport animals to central places for processing. They also helped move the finished meat products to distant markets.

Contents

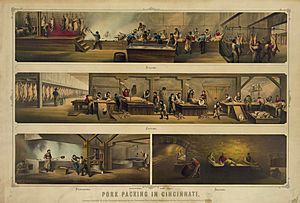

History of Meat Packing

In the United States

Before the American Civil War, meat production was mostly local. Farmers would provide animals to butchers who served their nearby towns. But after the war, big contracts for the Army encouraged people to think about selling meat to much larger areas. From 1865 to 1873, five main things helped the industry grow across the whole country:

- Cities were growing fast, creating a big new market for fresh meat.

- Large-scale ranching (raising animals on big farms) became popular.

- Railroads and refrigeration made it easier to move meat.

- Smart business people helped the industry expand.

- Cattle ranching moved to the Great Plains, from Texas northwards.

- Cattle drives moved large herds to train stations in Kansas. From there, cattle cars took the live animals east.

- Abilene, Kansas, became a major train hub, shipping thousands of cattle each year. Most went to Kansas City, Milwaukee, and Chicago.

In Chicago, famous stockyards (places where livestock are kept before slaughter) were built in 1865. Business leaders like Philip Armour and Gustavus Franklin Swift opened large plants there. Swift was especially good at shipping refrigerated meat over long distances to cities in the eastern U.S.

A useful refrigerated (ice-cooled) train car was introduced in 1881. This was a big deal! It meant companies could ship meat carcasses (the animal's body after slaughter) instead of live animals. Carcasses weighed much less, saving money. This opened up the entire national market, and even markets across the Atlantic Ocean using refrigerated ships. Swift created a system that included buying cattle, slaughtering them, packing the meat, and shipping it. This made his business huge, and other companies soon followed.

New laws also changed the industry. The Pure Food and Drug Act of 1906 and the Federal Meat Inspection Act were passed. These laws helped make sure food was safe and clean. They also helped larger meat packers because they had the resources to meet the new rules, while smaller companies found it harder.

Historian William Cronon noted that thanks to the big Chicago meat packers, ranchers had a reliable market for their animals and often got better prices. At the same time, people across America could buy more types of meat, and it was often cheaper than before.

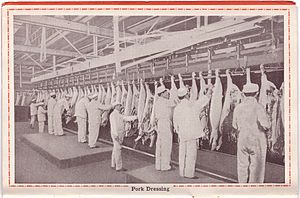

Working Conditions

In the early 1900s, meat-packing plants often had tough working conditions. They sometimes hired new immigrants or migrants to replace workers who went on strike. In 1906, a book called The Jungle by Upton Sinclair showed the public how bad the working conditions and unclean practices were in some meat-packing plants, especially in Chicago.

Meat-packing plants, like many factories back then, were known for making employees work too much. They didn't always have good safety measures and often fought against workers forming unions. Public pressure led the U.S. Congress to pass the Federal Meat Inspection Act and the Pure Food and Drug Act in 1906. These laws aimed to improve safety and cleanliness in the industry. Before these laws, workers faced dangerous chemicals, sharp machines, and serious injuries.

In the 1920s and 1930s, workers successfully formed unions, like the United Packinghouse Workers of America (UPWA). This union helped workers get better wages, hours, and benefits. The union also supported important causes like the Civil Rights Movement in the 1960s. For a few decades, even though the work was still hard, these jobs allowed workers to have good, middle-class lives.

Even with many improvements since the early 1900s, new challenges have come up in the meat-packing industry. Today, workers in meat packing are three times more likely to get seriously injured than the average American worker. Some reports say they are nearly seven times more likely to get injuries from doing the same movements over and over. The industry still employs many immigrant workers, including some who may not have legal papers. These workers can be at higher risk because it's harder for them to organize or get help for injuries.

Changing Locations

After 1945, many meat-packing companies closed their big city stockyards, like the famous ones in Chicago. They moved their operations to smaller towns closer to where cattle were raised, especially in states like Iowa, Nebraska, and Colorado. This shift happened because transportation changed from mostly trains to trucks. It also became harder for workers to form unions in these new, more rural locations. Over time, the number of jobs in the industry fell due to new technology and other changes. Wages also decreased. Both Chicago (in 1971) and Omaha (in 1999) eventually closed their stockyards.

In Argentina

Argentina had the resources to build a strong meat-packing industry. However, it was hard for them to sell their meat to Europe because of quality control issues and because frozen meat was not as good as the chilled meat from the United States and Australia. By 1900, the Argentine government encouraged investments to improve quality. British companies, which controlled world shipping, started using ships with cold air containers. This helped Argentina finally sell more meat to the British market.

In China

Meat became a much bigger part of the food supply in China in the late 20th century. This was because more people became middle class and had more money to spend on food. China went from providing only a small amount of meat for city dwellers to becoming the world's largest meat producer. Thousands of modern meat-packing plants opened across the country.

Health and Safety for Workers

Workers in American slaughterhouses face higher risks of injury than many other jobs. They are much more likely to suffer serious injuries or injuries from doing the same movements repeatedly. Safety measures are very important in these workplaces.

Working in slaughterhouses can also be very stressful for people. Studies have shown that workers in these jobs may experience lower overall well-being.

Another issue is that some important medicines, like heparin, use materials that come from the meat-packing industry. During the COVID-19 pandemic in 2020, many meat-packing plants had large outbreaks of the virus. This was due to close working conditions. This situation showed how important these plants are, but also how vulnerable their workers can be.

During the COVID-19 pandemic, meat-packing workers were often expected to process animals much faster. This was partly because there weren't enough workers. Many workers got sick because they worked closely together and were exposed to bacteria and viruses. Workers often had to shout over loud machines, which could spread germs more easily. More than 50,000 meat-packing workers caught COVID-19, and over 200 died.

Major Meatpackers

The "Big Four" (around 1900)

Around 1900, the biggest meat packers were:

The "Big Three" (in the 1990s)

In the 1990s, the main companies were:

- IBP

- ConAgra Foods

- Excel Corporation

Today's Major Meatpackers

Today, some of the most important meat packers in the United States include:

Beef Packers:

- Tyson Foods

- Cargill Meat Solutions (also known as Excel)

- JBS USA (also known as Swift)

- National Beef

Pork Packers:

- Smithfield Foods

- Seaboard Corporation

- Tyson Foods

- JBS USA

- Cargill Meat Solutions

Chicken Packers:

- Pilgrim's Pride

- Tyson Foods

- Perdue Farms

- Sanderson Farms

Outside the United States, some major meatpackers are:

- Teys Australia

- JBS S.A. (Brazil)

- BRF S.A. (Brazil)

- Charoen Pokphand Group (Thailand)

- Imperial Cold Storage and Supply Company (South Africa)

- Maple Leaf Foods (Canada)

- Schneider Foods (Canada)

- Cargill Proteins (Canada)

- AFFCO Holdings (New Zealand)

See also

In Spanish: Industria de procesamiento de la carne para niños

In Spanish: Industria de procesamiento de la carne para niños

- Animal–industrial complex

- Environmental impact of meat production

- Slaughterhouse

- Union Stock Yards, Chicago