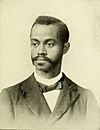

Gustavus Franklin Swift facts for kids

Gustavus Franklin Swift, Sr. (June 24, 1839 – March 29, 1903) was an American businessman. He created a huge meat-packing company in the Midwest. He ran this company until he passed away.

Swift is famous for inventing the first useful ice-cooled railroad car. This invention allowed his company to ship fresh meat all over the country and even abroad. This change led to a time of "cheap beef" for everyone. Swift also found ways to use animal parts that were usually thrown away. These parts were used to make things like soap, glue, and even medicines.

Gustavus Swift gave a lot of money to schools and churches. He helped the University of Chicago and the Methodist Episcopal Church. He also supported the YMCA. He started a special school at Northwestern University to honor his daughter, Annie May Swift. She had died while studying there. When he died in 1903, his company was worth a lot of money. It had over 21,000 workers. His company processed millions of cattle, hogs, and sheep each year. Swift and his family are buried in a special tomb in Mount Hope Cemetery in Chicago.

Contents

Gustavus Swift's Early Life and Business Beginnings

Gustavus Swift was born on June 24, 1839. He was the ninth of twelve children. His family lived on a farm in Sagamore, Massachusetts. They raised and processed cattle, sheep, and hogs. This is where Swift first learned about the meat business.

Swift did not enjoy school very much. He left after eight years. At age fourteen, he started working full-time in his older brother Noble's butcher shop. Two years later, in 1855, he started his own business. An uncle helped him with $400. Swift bought livestock in Brighton. He then drove them for ten days to Eastham. He was a smart businessman. He would sometimes not give his animals water before the end of the trip. This made them drink a lot when they arrived, which made them weigh more.

In 1861, Swift married Annie Maria Higgins. They had eleven children together. In 1862, Gustavus and Annie opened a small butcher shop. They also had a slaughterhouse. Seven years later, the family moved to Boston. In 1872, Swift became a partner in a new company called Hathaway and Swift. The company moved to Albany, then quickly to Buffalo.

Swift was very good at buying cattle. He saw that the market was moving west. In 1875, Hathaway and Swift moved again. They joined many other meat packers in Chicago's large Union Stock Yards. Swift became a very important person in "The Yards." His special delivery wagons were common sights on Chicago's streets.

In 1878, he formed Swift Bros and Company with his younger brother Edwin. This company became a major force in the Chicago meat packing industry. In 1885, it became Swift & Co. with Gustavus Swift as president. From this position, Swift changed how meat was processed, delivered, and sold. He died on March 29, 1903, in his home in Chicago.

How Chicago Became a Meat-Packing Hub

After the American Civil War, Chicago became a major railway center. This made it a perfect place to send livestock from the Great Plains to markets in the East. To get animals to market, herds were driven long distances. They went up to 1,200 miles to railheads in Kansas City, Missouri. There, they were loaded into stock cars. Then they were shipped live (on the hoof) to processing centers.

Driving cattle across the plains made them lose a lot of weight. Many animals also died during the trip. When they arrived, about 60% of an animal's weight was inedible. This made shipping live animals very costly and inefficient. Swift wanted to find a better way. He aimed to ship already processed meat from Chicago to the East.

The Invention of the Refrigerator Car

People tried to ship farm products by rail in the mid-1800s. In 1851, the Northern Railroad used an "icebox on wheels." This car worked only in cold weather. Other companies also tried shipping butter with ice.

The first processed beef left Chicago in 1857. It was carried in regular boxcars with ice bins. But placing meat directly on ice changed its color and taste. Swift tried shipping cut meat in open boxcars during winter. This method was too limited to be useful.

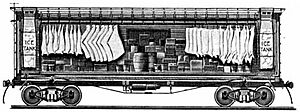

In 1878, Swift hired an engineer named Andrew Chase. Chase designed a new type of car. It was well-insulated and had ice in a compartment at the top. This allowed cold air to flow down naturally. The meat was packed tightly at the bottom. This kept the car stable and prevented the meat from moving.

Chase's design worked very well. It allowed Swift & Company to ship fresh meat across the United States and even to other countries. This completely changed the meat business. Swift tried to sell his design to major railroads. But they said no. They worried about losing money on their existing stock cars and animal pens.

So, Swift paid for the first cars himself. When American railroads still refused, he made a deal with the Grand Trunk Railway. This railroad didn't make much money from live cattle. They agreed to haul his new cars through Michigan and Canada. In 1880, the Peninsular Car Company built the first of these cars for Swift. The Swift Refrigerator Line (SRL) was born. Within a year, SRL had almost 200 cars. Swift was shipping about 3,000 processed animals a week to Boston. Other companies, like Armour and Company, quickly copied his idea. By 1920, SRL owned 7,000 ice-cooled rail cars.

Here is how much live cattle and dressed beef were delivered to New York:

| (Stock Cars) | (Refrigerator Cars) | |

| Year | Live Cattle | Dressed Beef |

| 1882 | 366,487 | 2,633 |

| 1883 | 392,095 | 16,365 |

| 1884 | 328,220 | 34,956 |

| 1885 | 337,820 | 53,344 |

| 1886 | 280,184 | 69,769 |

Using Every Part of the Animal

People were worried about pollution from meat packing plants. So, Swift looked for new ways to use animal parts that were usually thrown away. This led to making many different products. These included oleomargarine, soap, glue, and fertilizer. They also made hairbrushes, buttons, knife handles, and medicines like pepsin and insulin. Lower quality meats were canned into products like pork and beans.

Swift once famously said that his slaughterhouses used "everything but the squeal" of the pig. This meant they used almost every part of the animal.

Before there were federal inspections, some companies did not always use good practices. Sometimes, meat that was not fresh was repackaged and sold. These problems were shown in Upton Sinclair's famous book, The Jungle. The book shocked the country. It led to important laws like the Federal Meat Inspection Act and Pure Food and Drug Act in 1906. These laws made sure food was safer for everyone.

Controlling the Whole Process: Vertical Integration

Meat packing plants in Chicago were among the first to use assembly line methods. In an assembly line, work is divided into many small steps. Each worker does one specific task. Henry Ford, who created the Ford car company, said he learned about assembly lines from visiting a Chicago slaughterhouse.

Swift used these modern methods in his meat packing plants. This made his operations very efficient. It allowed his plants to produce huge amounts of meat. Swift & Co. was organized into different parts. Each part was in charge of a different step. This was called "vertical integration." It meant Swift controlled everything. He controlled the process from the farm to the local butcher shop.

Swift spent a lot of time teaching his employees. He taught them the company's ways and rules. He also encouraged them to work hard for the company's goals. He did this by promoting people from within the company. Swift's ideas changed the meat packing industry forever. They also helped create the modern American business system. This system focuses on making many products, having specialized jobs, and using new technology.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |