Panama Canal locks facts for kids

The Panama Canal locks are a clever system of water elevators. They help ships travel across the Panama Canal. These locks lift ships up about 26 meters (85 feet) to the main level of the canal. Then, they lower the ships back down to sea level.

When the canal first opened in 1914, it had six "steps" for ships. Three steps lifted ships up, and three steps lowered them down. The entire lock system, including the walls leading to them, is over 3 kilometers (1.9 miles) long. Building these locks was one of the biggest engineering projects ever at that time. No other concrete structure as large was built until the Hoover Dam in the 1930s.

The canal has two separate paths for ships. This is because each lock is built as a double system. The size of the original locks limited how big ships could be to pass through. This maximum size is called Panamax. In 2007, work began on a new set of locks. This Panama Canal expansion project finished in 2016. The new locks allow even bigger ships, called New Panamax ships, to use the canal. These larger ships can carry much more cargo.

Contents

How the Locks Work

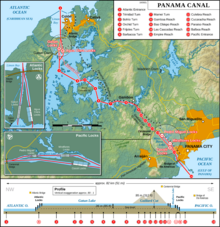

There are 12 locks in total. On the Pacific side, ships go through two steps at Miraflores and one step at Pedro Miguel. These steps lift them up to Gatun Lake. Then, on the Atlantic side, three steps at Gatun lower them down.

All three sets of locks are built in pairs. This means there are two parallel paths at each lock location. In theory, ships could go in opposite directions at the same time. However, large ships cannot pass each other safely in the narrow Culebra Cut. So, ships usually travel in one direction for a while, then in the other. Both paths of the locks are used for ships going in the same direction. This paired system is also helpful if one lock needs repairs or has a problem.

The lock chambers are huge concrete boxes. They are about 33.5 meters (110 feet) wide and 320 meters (1,050 feet) long. The part ships can actually use is about 305 meters (1,000 feet) long. These sizes set the limit for how big a ship can be to use the canal. This limit is known as Panamax.

The Gatun locks lift ships about 26 meters (85 feet). The Miraflores locks lift ships about 16.5 meters (54 feet). The Pedro Miguel locks lift ships about 9.4 meters (31 feet). The water level at Miraflores changes a lot because of the extreme tides on the Pacific side. It can vary between 13 meters (43 feet) at high tide and 19.7 meters (64.5 feet) at low tide. The tides on the Atlantic side are very small.

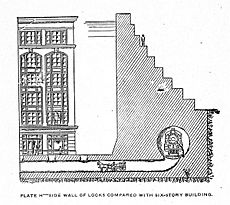

The side walls of the lock chambers are very thick. They are about 14 to 17 meters (45 to 55 feet) thick at the bottom. They get thinner towards the top, tapering to about 2.4 meters (8 feet) thick. The wall in the middle, between the two parallel chambers, is 18 meters (60 feet) thick. This middle wall has three tunnels running through it. The lowest tunnel is for drainage. Above that is a tunnel for electrical cables. The top tunnel is a walkway for operators to reach the lock machinery.

Filling and Draining the Locks

Each lock chamber needs a lot of water to fill it up. It takes about 101,000 cubic meters (26,700,000 US gallons) of water to raise a ship. The same amount of water is drained out to lower a ship.

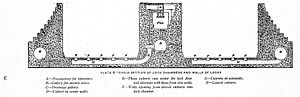

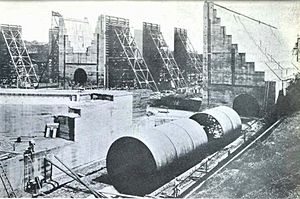

Inside the side and center walls are three large water tunnels, called culverts. These culverts carry water from the lake into the chambers to raise ships. They also carry water from one chamber down to the next, or out to the sea, to lower ships. These culverts start at 6.7 meters (22 feet) wide and shrink to 5.5 meters (18 feet) wide. They are big enough for a train to pass through!

Smaller culverts branch off from these main ones. They run under the lock chambers and have openings in the floors. Each chamber has 14 of these cross culverts, with five openings each. Seven come from the side wall culverts, and seven from the center wall culvert.

Water moves through the locks by gravity. Huge valves in the culverts control the water flow. Each cross culvert can be controlled separately. A lock chamber can be filled in as little as ten minutes.

Lock Gates

The gates that separate the lock chambers are very important. They must hold back a huge amount of water. They also need to be strong and reliable to prevent accidents. If a gate failed, a flood of water could rush downstream.

These gates are between 14 and 25 meters (47 to 82 feet) high, depending on their location. They are 2.1 meters (7 feet) thick. The tallest gates are at Miraflores because of the big tidal changes there. The heaviest gate parts weigh 662 tons (652 long tons). The hinges alone weigh 16.7 tons (37,000 pounds) each.

Each gate has two parts, called leaves. Each leaf is about 20 meters (65 feet) wide. They close to form a "V" shape, with the point facing upstream. This design means the force of the water from the higher side pushes the ends of the gates tightly together. The gates can only open when the water level is the same on both sides.

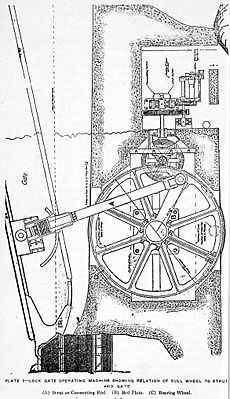

The original machines that opened the gates used a large drive wheel powered by an electric motor. This motor was connected to a rod, which then attached to the middle of the gate. The gates are hollow and float, much like a ship's hull. They are so well balanced that two small 19 kilowatt (25 horsepower) motors are enough to move each gate leaf. If one motor stops working, the other can still operate the gate, just at a slower speed.

Almost every chamber has a pair of extra gates. These can divide the chamber in two. This allows smaller ships, less than 180 meters (600 feet) long, to pass through without using all the water. These extra gates were added because most ships in the early 1900s were shorter than 180 meters. So, they didn't need the full length of the lock chamber.

Mules (Locomotives)

From the very beginning, it was decided that electric locomotives would guide ships through the locks. These locomotives are called mulas (Spanish for "mules"). They are named after the animals traditionally used to cross the Isthmus of Panama. These "mules" run on tracks along the lock walls. They help control the ship from side to side and act as brakes. The ship's own engines provide the forward motion, not the mules.

When a ship comes to the locks, it first pulls up to a guide wall. This wall is an extension of the middle wall of the locks. Here, the mules take control of the ship before it enters the lock. As the ship moves forward, more lines are attached to mules on the other wall. For large ships, there are two mules on each side at the front and two on each side at the back. That's eight mules in total! This allows for very precise control of the ship. However, the new expansion locks do not use mules.

The mules run on special railway tracks that are 5 feet wide. The track closest to the canal is for towing and has special "rack tracks" for geared operation. The track further inland is used for the mules to return to their starting point. It doesn't have rack tracks, except on steep slopes between lock chambers. The mules get their power from electricity. This power comes from a "third rail" laid below the surface on the land side. Each mule has a powerful winch. These winches pull or release cables to keep the ship centered in the lock as it moves from one chamber to another.

Safety Features

If the lock gates failed, for example, if a runaway ship hit a gate, it could cause a flood. The large lakes above the locks (Gatun Lake or Miraflores Lake) would drain through the lock system. To prevent this, the gates at both ends of the upper chamber in each set of locks are doubled. This means there are always at least two gates that would have to fail for the water to rush downstream. These extra gates are about 21 meters (70 feet) away from the main operating gates.

Originally, the locks also had chain barriers. These chains stretched across the lock chambers. They were meant to stop a ship from going out of control and hitting a gate. They could be lowered into the lock floor to let the ship pass. These "fender chains" had special braking systems. They could safely stop a ship weighing up to 10,000 tons. However, because the mules controlled ships so precisely, these chains were rarely needed. Many modern ships using the canal weigh over 60,000 tons. Because of this, and the cost of keeping them, the fender chains were removed in 1980.

The original design also included emergency dams. These were swinging bridges that could be moved across the locks at the upper end of each set. From these bridges, steel beams could be lowered to the lock floor. Then, steel shutters would slide down these beams to block the water flow. These emergency dams were never used and were removed in the 1950s.

In the late 1930s, new emergency dams replaced the original ones. These new dams would rise out of slots in the bottom of the lock chambers. They were operated by hydraulics or compressed air. The new dams were taken out of service in the late 1980s. Today, there are no emergency dams in place.

Controls

All the lock equipment works using electricity. This means the whole process of moving a ship up or down can be controlled from one central room. This control room is located on the middle wall of the upper set of locks. The controls were designed to prevent mistakes by operators. They include a full model of the locks. This model has moving parts that show exactly what the real lock gates and valves are doing. So, the operator can see the exact state of the locks and water valves. The controls also have mechanical safety features. These make sure that one part cannot move if another part is in the wrong position. For example, you cannot open the drain and fill valves of a lock chamber at the same time.

Construction

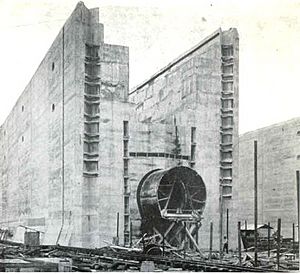

Building the locks started on August 24, 1909, at Gatun. The company Day & Zimmermann laid the first concrete.

The Gatun locks were built into a hill next to the lake. This required digging out about 3.8 million cubic meters (5 million cubic yards) of material, mostly rock. The locks themselves used about 1.56 million cubic meters (2,046,100 cubic yards) of concrete.

A lot of stone and cement were needed to build the locks. Stone for the Gatun locks came from Portobelo. For the Pacific side, stone was taken from Ancon Hill.

Huge overhead cableways were built to carry concrete to the Gatun construction site. Towers, 26 meters (85 feet) high, were built on the banks of the canal. Steel cables, 6.4 centimeters (2.5 inches) thick, stretched between them across the locks. Buckets running on these cables carried up to six tons of concrete at a time into the locks. Electric railways brought stone, sand, and cement from the docks to the concrete mixing machines. From there, another electric railway carried two 6-ton buckets at a time to the cableways. The smaller constructions at Pedro Miguel and Miraflores used cranes and steam locomotives in a similar way.

The locks on the Pacific side were finished first. The single lock at Pedro Miguel was ready in 1911. The Miraflores locks were finished in May 1913.

The tugboat Gatun was the first ship to try out the Gatun Locks. This happened on September 26, 1913. The test went perfectly, even though all the valves had to be controlled by hand because the central control board wasn't ready yet.

Map

See also

In Spanish: Esclusas del canal de Panamá para niños

In Spanish: Esclusas del canal de Panamá para niños

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |