South Burnett Co-operative Dairy Association Factory facts for kids

Quick facts for kids South Burnett Co-operative Dairy Association Factory |

|

|---|---|

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

| Location | Macalister Street, Murgon, South Burnett Region, Queensland, Australia |

| Design period | 1919 - 1930s (interwar period) |

| Built | 1929 |

| Architect | George Gerald Hutton |

| Official name: South Burnett Co-operative Dairy Association Factory (former) | |

| Type | state heritage (built) |

| Designated | 9 November 2012 |

| Reference no. | 602811 |

| Significant period | 20th century 1913-1990s |

| Significant components | factory building, engine/generator shed/room / power supply |

| Builders | H Taylor |

The South Burnett Co-operative Dairy Association Factory is a historic building in Murgon, Queensland, Australia. It used to be a factory where dairy products were made. The famous architect George Gerald Hutton designed it, and H Taylor built it in 1929. This important site was added to the Queensland Heritage Register on 9 November 2012.

Contents

A Look Back at the Factory's History

The former South Burnett Co-operative Dairy Association Ltd Factory in Murgon has many buildings from different times, starting in 1908. It was a very important place for making dairy products in the region from 1913 until 1995.

How Dairying Grew in Queensland

In the late 1800s, several things helped the dairy industry grow in Queensland. The government made more land available for farming. New machines like mechanical cream separators (in the 1880s) and Babcock testing (to measure cream accurately) made dairy farming easier.

The government also offered loans to build butter and cheese factories. The Queensland Department of Agriculture and Stock even had a "Travelling Dairy" to show farmers new techniques. Better types of grass for cows and growing food for them also helped increase milk production.

The Importance of Railways

Good transport was key for dairy products to reach markets. Expanding Queensland's railway network helped move dairy goods faster. This led to more butter and cheese factories being built near railway lines. The first butter was shipped to Britain in 1895.

When the Kilkivan branch railway reached Murgon in 1904, it helped the town grow. It also boosted the dairy industry in the surrounding South Burnett area.

The Rise of Co-operatives

By the early 1900s, groups of local farmers often worked together to build factories. These groups were called "co-operatives." This became the main way cheese and butter factories were owned in Queensland.

In 1908, the Tiaro Dairy Co-operative Company started. They built a timber butter factory that same year. Many farmers from the South Burnett sent their cream to this factory. A cream collection point was set up in Murgon, and cream was sent to Tiaro by train.

By 1912, most of the cream for the Tiaro factory came from the South Burnett. So, in August 1912, the co-operative decided to move the factory to Murgon.

The Murgon Factory Begins

A new site was bought on Macalister Street in Murgon in August 1913, close to the Murgon railway station. The Tiaro factory was moved there, and it started working in September. Mr George Wood built the factory, and Waugh and Josephson supplied the machines.

The factory could now make 40 tons of butter per week, up from 12 tons at Tiaro. In early 1914, the co-operative changed its name to the South Burnett Co-operative Dairy Company Limited (SBCDC). Later that year, a railway track was built right to the factory.

Growing Bigger and Better

The Murgon butter factory grew steadily, showing how good the South Burnett area was for dairying. In 1913, it had 250 cream suppliers. By 1929, it had 800! Butter production also jumped from 252 tons in 1913 to 1644 tons in 1928.

This growth meant the factory needed to expand in 1929. The company decided to build a new section that could make 35 tons of butter. This new part would work with the old one. They also built a power plant strong enough to run both sections.

The idea was to use both parts of the factory to make butter in the morning. The rest of the day would be for handling new cream deliveries. This "dual factory system" was said to be "unique" in Australia at the time. It increased the factory's total butter production to 64 tons a week, or 128 tons with double shifts.

Brisbane architect George Hutton oversaw the building plans. Mr H. Taylor, also from Brisbane, was the builder. The upgrades cost more than £25,000. The largest new building was made of reinforced concrete with a special truss roof and a lantern roof. The engine room was built behind it.

The new buildings officially opened on 9 March 1929. William Forgan Smith, the Minister for Agriculture, was there. Over 1000 guests attended, and the town celebrated!

Many butter factories in Queensland were updated around this time. They replaced old timber buildings with new ones made of brick and concrete. Factories also added more churns and focused on making high-quality butter. They used modern methods like pasteurisation and had more trained staff.

How Butter Was Made

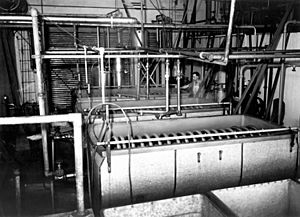

Making butter followed a common process. First, cream cans were received and weighed. The cream was tested to see its quality (choice, 2nd, or 3rd grade). Then, the cans were emptied into large vats and cleaned to be returned to the farmers.

Next, the cream was pasteurised (heated to kill germs), cooled, and sent to storage vats. From there, it went to the churns. After churning, the butter was refrigerated, packed into boxes, and sent by train for export.

Dairying's Golden Age and Decline

The years between World War I and World War II were a boom time for dairying in Queensland. The number of dairy cows grew by 50 percent between 1927 and 1937. By the 1930s, dairying was Queensland's most widespread farm industry. It was also the state's second most profitable export from 1936 to 1941.

By the late 1930s, about one in eight Queenslanders lived on dairy farms. In 1938, the South Burnett had five co-operative butter factories: in Nanango (Nanango Butter Factory Building), Kingaroy, Murgon, Wondai, and Proston. These factories helped produce and export dairy products. However, the industry relied on many small farms where families milked cows twice a day for modest earnings.

With its increased production, the Murgon butter factory became Queensland's fourth largest butter producer by 1931. Production peaked in 1934, making 2873 tons.

However, demand and prices for butter dropped in the 1950s. People started eating more margarine. This led to a decline in dairying. Many smaller farmers left the industry as it shifted towards producing milk instead of cream, which needed bigger herds and new equipment. Export opportunities also became limited, especially after Britain joined the European Common Market in 1973.

Changes and Closure

In the late 1960s, butter factories in the Burnett region began to close. The Proston Butter Factory closed in 1967. The Maryborough Co-operative Dairy Company closed its factories in Wondai and Biggenden in 1969. By 1976, there were fewer than 400 dairy farmers left in the South Burnett.

The Murgon butter factory survived longer because it started making other dairy products from the 1940s. It began making cheese in late 1942 during wartime. While other factories stopped making cheese after the war, Murgon continued until the 1990s.

In 1948, the factory started selling pasteurised bottled milk. In 1953, they installed a modern pasteurisation and bottling plant. They also built a new office and a dairy research laboratory. In 1960, a new building was added to make buttermilk powder from the liquid left over after churning butter.

When the Nanango and Kingaroy butter factories closed in 1977, all cream supplies went to Murgon. It was the last dairy factory left in the South Burnett. In 1978, new milk processing facilities opened. They started making skim milk in 1979 and later, flavoured milk drinks.

By 1995, butter production had stopped. A drop in demand for cheddar cheese forced the Murgon factory to close. This marked the end of dairy processing at the site.

In 1998, Clovely Estate bought the factory. Since then, it has been used for making wine, which is a new industry in the South Burnett.

What the Factory Looks Like Today

The former Murgon Butter Factory is located at the corner of Macalister and McLucas Streets in Murgon. It's next to where the Kilkivan/Kingaroy railway line used to be. The site has many buildings and structures from different times when dairy products were made. These include the old Tiaro Butter Factory, the main building (from 1929), the plant room, and the boiler shed with its tall chimney.

The Main Building (1929)

The main building faces the loading yard on Macalister Street. It's a rectangular concrete shed with decorative stepped walls at the top. These walls hide a gable roof covered with corrugated metal. The front side has seven sections, some with windows and some with large timber doors for the loading dock. The words "The South Burnett Co-operative Dairy Association Ltd" are written on the decorative wall.

Inside, the roof has steel trusses, and the ceiling is lined with particle board. The floor is concrete, and a raised concrete loading dock runs along two sides. A narrow vent with windows and timber louvres runs along the roof's peak.

A concrete loading dock with a metal awning runs along the side facing Macalister Street. Old railway tracks run next to the dock.

The Old Tiaro Butter Factory Buildings

Two rectangular timber buildings from the original Tiaro butter factory are still on the site. They have gable roofs covered with corrugated iron. These buildings contain rooms that were used for processing dairy products, including cold and salt rooms. They have brick and concrete walls, timber floors, and some rooms have curved ceilings.

Newer cold rooms and lab areas are now in the northern part of the old loading dock. The space between the old Tiaro buildings and the main 1929 building is covered by a sloped roof and is open to the dock.

Other Old Structures

Other older buildings used for making butter and milk include a timber shed on the McLucas Street side and a small timber shed with two gable roofs south of the chimney.

The Plant Room

The plant room is a rectangular building in the middle of the site. It has a steel frame and concrete walls, with a gable roof of corrugated metal. Inside, the concrete walls are plastered and painted. The floor is concrete, and low concrete stands hold various machines. The timber roof is open, with a narrow vent at the top. Two large steel-framed windows are on one wall, and a double timber door opens to the other side. A newer cold room is attached to one side.

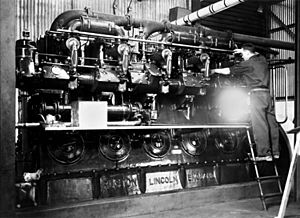

This shed holds many machines, including engines, pulleys, belts, pipes, gauges, and equipment for the ammonia chilling process.

The Boiler Shed and Chimney

Two round metal boilers with brick fireboxes are inside a timber shed with a hipped roof, covered in corrugated iron. The fireboxes have metal fronts with openings. Each firebox connects to the tall chimney by a brick tunnel.

The shed has a concrete floor and short trolley tracks near the fireboxes. One side has three large open window openings. The shed also contains other equipment related to the boilers, like ladders and pipes.

The tall brick chimney is square at the bottom and gets narrower towards the top. It has decorative stepped edges at the bottom and top.

Newer Buildings

Three newer buildings made of concrete blocks are also on the site. These were built later for the dairy business but are not considered historically important.

The site also has several new structures related to the current wine-making business, such as tanks and storage rooms. These are also not considered historically important.

Why This Place is Important

The South Burnett Co-operative Dairy Association Factory (former) was listed on the Queensland Heritage Register on 9 November 2012 because it meets certain important criteria.

It Shows How Queensland's History Changed The Murgon factory, which made dairy products from 1913 to 1995, shows how Queensland's dairy industry grew and changed in the 1900s. It was one of Queensland's biggest butter makers during the dairy boom years. It was also one of the largest and most important dairy factories in the Wide Bay-Burnett region for a long time.

The parts of the Tiaro butter factory that were moved to Murgon in 1913 show how fast dairy farming grew in the South Burnett in the early 1900s. The factory's expansion in 1929 shows how it adapted to more cream production and used modern ways of making butter. Later changes from the 1940s show how the factory shifted from making mostly butter to making cheese and milk products, as the market changed.

It Shows What a Dairy Factory Is Like The South Burnett Co-operative Dairy Association Ltd Factory (former) is a great example of what a dairy factory looks like and how it works. It's located next to a railway line, which used to have a special track for moving products. Inside, the buildings are connected and have areas for receiving cream, large rooms for making butter, milk, and cheese, and cold storage areas.

The 1929 engine room with its remaining equipment (like the ammonia compressor and pipes), along with other factory parts (the large brick chimney, boilers, and sheds), show the industrial needs of the complex over time.

Images for kids