Unitary Plan Wind Tunnel (Mountain View, California) facts for kids

|

Unitary Plan Wind Tunnel

|

|

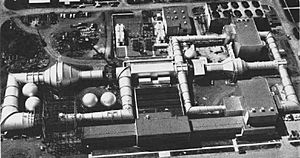

Aerial view of the Unitary Plan Wind Tunnel complex, 1974

|

|

| Location | Mountain View, California |

|---|---|

| Built | 1955 |

| NRHP reference No. | 85002799 |

Quick facts for kids Significant dates |

|

| Added to NRHP | October 3, 1985 |

| Designated NHL | October 3, 1985 |

The Unitary Plan Wind Tunnel is a special research place at the NASA Ames Research Center in Moffett Federal Airfield, Mountain View, California. It helps engineers design and test new airplanes and space vehicles. This includes big passenger planes, military jets, and even NASA's own space vehicles like the Space Shuttle. The facility was finished in 1955. It is one of five important places built after a special law in 1949 to help with flight research.

Contents

Why Was This Wind Tunnel Built?

After the first big wind tunnel was built in 1921, America became a leader in making airplanes. But by 1945, other countries were catching up. New technologies like missiles and jet aircraft showed that America needed to improve its flight research.

So, in 1949, the U.S. Congress passed a law called the Unitary Wind Tunnel Plan Act. This law helped the government, the Air Force, private companies, and universities work together. They built many new wind tunnels. The Ames Unitary Plan Wind Tunnel Complex was one of these important new facilities.

How Was the Wind Tunnel Constructed?

Building this huge facility started in 1950 and finished in 1955. No single wind tunnel could test every type of aircraft or missile. So, NASA decided to build the Ames tunnel with three different test sections. All three sections share one powerful motor system.

The transonic test section is 11 by 11 feet (3.3 x 3.3 meters). This section tests planes flying near the speed of sound. The two supersonic sections are smaller. One is nine by seven feet (2.7 x 2.1 meters), and the other is eight by seven feet (2.4 x 2.1 meters). These test planes flying faster than the speed of sound. Giant valves, 20 feet (6 meters) wide, move air between the supersonic sections.

The Unitary Plan Wind Tunnel has three closed-loop tunnels. Each tunnel has its own place to test models. But they all use the same powerful motors. These motors power huge compressors that push air through the tunnels. Because they share motors, only one test section can be used at a time.

Here are the three main parts of the system:

- 11-by 11-foot Transonic Test Section: This tunnel can test models at speeds from Mach 0.20 to Mach 1.45. Mach 1 is the speed of sound.

- 9-by 7-foot Supersonic Test Section: This tunnel tests models at speeds from Mach 1.55 to Mach 2.55.

- 8-by 7-foot Supersonic Test Section: This tunnel tests models at speeds from Mach 2.55 to Mach 3.5. This section was stopped in the early 1990s.

The Unitary Plan Wind Tunnel was named a National Historic Landmark in 1985. This means it is a very important historical place.

What Has Been Tested Here?

The Unitary Plan Wind Tunnel has helped design many famous aircraft. Companies like Boeing and Douglas tested their commercial planes here. These include the Douglas DC-8, DC-9, and DC-10. Military planes like the F-111 fighter, the C-5A Galaxy transport, and the B-1 Lancer bomber were also tested.

Beyond airplanes, all of NASA's human space vehicles have been tested here. This includes the Space Shuttle and the new SLS rocket. These tests helped make sure they were safe and worked well in flight.

How Does the Drive System Work?

The most important part of the tunnel is its main drive system. This system has four powerful electric motors linked together. Each motor can create up to 65,000 Horsepower and uses 7200 volts of electricity. Together, the system can produce a massive 260,000 horsepower! This incredible power pushes the air through the tunnels at very high speeds. A special liquid system helps control the speed of these motors.

The 11-foot Transonic Wind Tunnel

The 11-foot transonic wind tunnel is a closed tunnel. It can create speeds from Mach 0.25 to Mach 1.4. A three-stage compressor creates the airflow. To reach Supersonic speeds, a flexible wall moves to form a special shape called a De Laval nozzle.

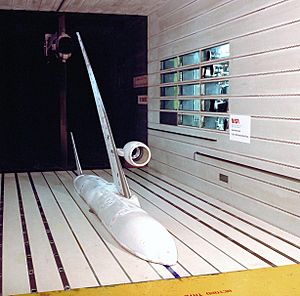

Models tested here are often full-size (mounted on a "sting") or half-size (mounted on the floor). The sting mount can move the model to different angles. This helps engineers see how the plane will fly in various positions.

Engineers measure many things during tests. They check forces, pressures, and temperatures on the model. They also use special cameras and paints. These tools help them see how air flows over the model. Examples include Shadowgraph (like Schlieren) and Pressure-sensitive paint.

The 9x7-foot Supersonic Wind Tunnel

The 9x7-foot supersonic wind tunnel can reach speeds from Mach 1.55 to Mach 2.5. The Mach number is set by moving a special sliding block. An 11-stage compressor, weighing over 450 tons, creates the powerful airflow.

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |