Universal nut sheller facts for kids

The universal nut sheller (UNS) is a simple machine that helps people remove the outer shells from nuts. It was once called the Malian peanut sheller. This machine works by hand and can shell up to 57 kilograms (about 125 pounds) of dried peanuts in just one hour.

It costs less than $10 USD to make the materials for this machine. It is built from concrete, some metal parts, a wrench, and a rock or piece of wood. The UNS can shell many different sizes of nuts without needing big changes. People can adjust it quickly and easily. One universal nut sheller can help a village of 2,000 people. The machine is expected to last for about 25 years. The Full Belly Project is a group that helps make and share useful tools like the Universal Nut Sheller in local communities.

Contents

How the Universal Nut Sheller Started

In 2001, a man named Jock Brandis went to Mali to fix a village's water system. While there, a woman told him that her village really needed an affordable machine to shell peanuts. When Jock returned to the United States, he talked to Dr. Tim Williams, an expert on peanuts. Dr. Williams told Jock about a peanut shelling design from Bulgaria.

Jock worked with his friend, Wes Perry, to change and improve this design. Jock made several new versions of the machine. One year later, he finished the machine we now call the Universal Nut Sheller.

The Full Belly Project

In 2003, Jock Brandis joined with a group of volunteers from North Carolina. They had all worked with the Peace Corps before. Together, they started the Full Belly Project. This group works to create and share special helpful tools in developing countries.

How the Machine Works

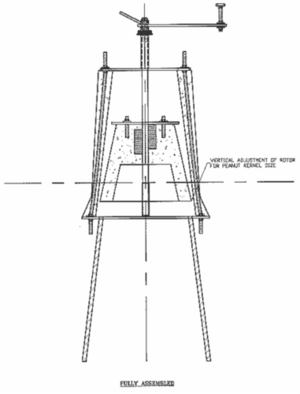

To use the machine, a person puts the nuts into the space at the top. The user then turns a handle, which makes a part inside, called the rotor, spin around. This spinning motion helps the nuts move down a space that gets narrower and narrower.

The shell of each nut breaks when the space becomes small enough and the spinning rotor creates enough rubbing to crack it open. The machine can be adjusted to fit different nut sizes. The shelled nuts and broken shell pieces fall into a basket. Later, people separate the nuts from the shells using a process called winnowing. This machine works best for plants like Jatropha curcas, shea nuts, dried coffee beans, and peanuts.

Pedal-Powered Sheller

The Full Belly Project also made a version of the universal nut sheller that uses pedals, like a bicycle. This pedal-powered machine has a fan connected to it. The fan automatically separates the shells from the nuts (winnows them) as the nuts are shelled.

These pedal-powered machines can shell the same types of crops as the hand-cranked ones. The winnowing part can also be used by itself. This means it can clean crops that don't need shelling, such as rice, maize (corn), and sorghum.

Challenges Faced by the Sheller

The universal nut sheller has not always worked well in Ghana. Many users there reported that the nuts broke too easily. People can try to prevent this by starting with a very wide setting and then making it narrower. However, this does not stop all breakage and makes the machine less efficient. Also, shelling peanuts is often a social activity that people do together in their free time, so a machine is not always needed.

The Universal Nut Sheller also had trouble shelling shea nuts from trees in Ghana for making shea butter. But, it has been reported to work well for shea nuts from trees in Uganda.

The cost of the machine was also a problem for some. It was simply too expensive for individual farmers to buy, even without counting the cost of molds or transport. However, groups of farmers who bought the machine together have found it to be successful.

Awards and Recognition

- 1st place - Popular Mechanics 2006 Breakthrough Awards.

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |