Annery kiln facts for kids

The Annery Kiln is an old limekiln (a special oven for making lime) located on the Annery estate in Monkleigh, North Devon. It sits right next to the River Torridge, close to the Half-Penny Bridge, which was built in 1835. This bridge connects Monkleigh and Weare Giffard. Today, the A386 road, which goes from Bideford to Great Torrington, runs right by it.

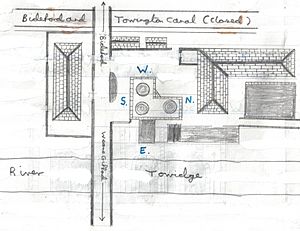

Weare Giffard is where the river starts to be affected by tides. This was a perfect spot for the kiln because raw materials could be brought in by boat. The lime made here was used as a fertilizer for farms further inland. The old limekiln is found between the River Torridge and the Rolle Canal, which was built around 1827. There was also a railway line, opened in 1872 and closed in 1966, that used to run from Bideford to Torrington. This old railway path is now part of the Tarka Trail, a popular walking and cycling route.

Contents

A Look Back: History of Annery Kiln

Weare Giffard is near the point where the River Torridge becomes tidal. This meant that coal and limestone could be brought up the river by boat long before the Rolle Canal was built between 1823 and 1827.

Why Location Mattered for Lime Kilns

The product of a lime kiln is called quicklime, and it's very strong and can corrode things. Because of this, it was really important to build kilns as close as possible to the farms where the lime would be used. If quicklime got wet during transport, it could damage the farmer's cart or even the animal carrying it!

Materials Used

The coal used, called "culm" (a type of anthracite), was mined in Devon at places like Tavistock and Chittlehampton. It was also brought in from South Wales through Bideford. Most of the limestone came from Caldey Island off the South Wales coast, but there were also quarries in Devon at Landkey, Swimbridge, Filleigh, South Molton, and Combe Martin.

What the Kiln Complex Included

The Annery limekiln site included the kiln itself, a pond for "slaking" the quicklime (adding water to turn it into slaked lime), and several cottages for the workers. These workers included lime-burners, shipbuilders, and blacksmiths. There were also storage buildings. A small wharf on the river allowed boats to unload their materials.

How the Kiln Was Built

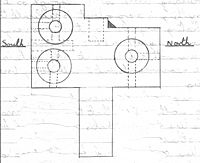

The Annery limekiln has a ramp facing the river. It has three burning "pots" (the main chambers where the lime was made), seven entrance doorways, and nine smaller openings at the bottom for removing the finished lime. The way the kilns are arranged makes the whole structure look like an L-shape. Some entrances led to arched areas called "eyes," where the grates were. There were also "poking holes" to insert metal rods to help the burning process.

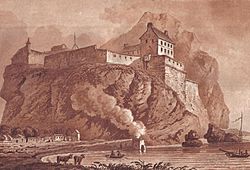

The top of the kilns was flat and big enough to store some coal and limestone. Like other kilns owned by Lord Rolle, these kilns were later decorated with castle-like battlements (a fancy, decorative feature). This was probably added by John Rolle, 1st Baron Rolle (who died in 1842), who owned the land and helped build the Rolle Canal and Half-Penny Bridge. The original Annery kiln was built before Lord Rolle's canal, so it probably didn't have these castle decorations at first.

Annery Kiln was very well built using local stones, mortar, and special firebricks inside the burning chambers. The openings have rounded or pointed Gothic arches made from bricks. The now-lost castle-like tops were similar to other kilns in the area.

Evidence suggests that the original kiln had only one pot and three arched entrances. Later, two more pots were added, and these had rounded arches with only two entrances each. The front of the newer part of the kiln has decorative "blind arches" (arches that are filled in) and two quatrefoils, which are symmetrical shapes made of four overlapping circles.

Transport and Demand

The kiln had excellent transport links. It was originally just by the river, but then the canal, the road between Bideford and Torrington, and the new Half-Penny toll-bridge (built in 1835) were added. In the 1800s, there was a huge demand for agricultural lime in Devon. Farmers from a wide area would come to Annery to collect loads of lime, first by pack-horse and later by wagons. They sometimes arrived as early as 4 AM to make sure they got their supply for the day.

Why the Kiln Closed

The growth of the railway network eventually made small local kilns less profitable. Annery Kiln closed around 1864, even before the local railway line opened. Strong competition from other lime kilns in Torrington and nearby areas also played a part in its closure.

Annery Kiln in 1971

How Limekilns Work

Function of a Limekiln

Annery Kiln had three burning chambers, all made of brick. Each chamber had an air inlet (called an "eye") at the bottom. Crushed limestone and coal, brought by boat from the nearby River Torridge or the Rolle Canal, were pulled up the ramp and dropped into the kiln chamber. Workers would build up layers of coal and limestone inside the kiln, on top of grate bars across the "eye" at the bottom.

Once the kiln was loaded, a fire would be started at the bottom. The fire would slowly spread upwards through the layers of material. After the burning was complete, the lime would cool down and then be raked out through the bottom openings.

The size of each kiln was limited because air needed to flow freely, and too much weight could cause a collapse. This is why individual kilns were all about the same size, and multiple kilns (like the three at Annery) were needed to produce more lime. Each kiln usually made between 25 and 30 tonnes of lime in one go. At Annery, they might have fired the kilns one after another to make sure there was always a supply of lime.

Typically, it took about one day to load a kiln, three days to burn the materials, two days to cool, and one day to unload. Getting the right amount of burning was tricky and often done by trial and error, by changing how much fuel was used. There were big temperature differences inside the kiln, so the final product was usually a mix of under-burned, well-burned, and "dead-burned" (unreactive) lime. This job was very hard work, with loading and unloading teams working in shifts. The heat was intense, and there was a lot of smoke, making it a dangerous job.

Lime and Its Uses

Lime kilns are used to make quicklime by heating limestone to a very high temperature (around 900-1000°C). This process is called calcination. If the temperature gets too high, the lime becomes "dead-burned" and isn't as useful.

Lime is used in building as a mortar (the cement-like material that holds bricks together) and to stabilize mud walls and floors. It's also widely used in agriculture to improve soil. Using lime became much more common when coal became cheaper, making the production process more affordable.

Before modern transport, moving heavy materials like limestone and coal by land was difficult because roads were often in poor condition. So, these materials were usually moved by sea. Lime was often made at small ports along the coast and then taken inland by carts. Many old kilns can still be seen on quaysides (docks) around the coastline of the United Kingdom.

More About Annery and Weare Giffard

Annery is a historic estate nearby. Old maps show that a large country house called Annery existed there in the 1700s. There was another lime kiln across the river from Weare Giffard, so the name "Annery Kiln" might have been used to tell them apart. Or, Annery Kiln might have been the main kiln for the local estate, supplying its tenants.

In 1971, during a visit to Annery Kiln, one of the old cottages had a chimney fire! The person living there solved the problem by firing both barrels of a shotgun up the chimney, which put out the fire and cleaned the chimney at the same time!

In the 1970s, the kiln was used as a garage and storage area (as shown in the photographs). The area around it was known as Annery Kiln and was a small community itself.

The small shipyard that used to be at Annery moved closer to the sea lock when the canal was built. William Tardrew of Annery was a part-owner in the Rolle Canal Company and owned land along the canal.

Next to Annery Kiln is Brick Marsh, which was once the site of the Devon or Annery Pottery.

The village name is sometimes spelled Weare 'Giffard' and sometimes 'Gifford', with 'Giffard' being more common. The Giffard family has been recorded in the area since at least 1219. Annery was first mentioned as 'Auri' in 1193.

The Beam Aqueduct (shown in an illustration) has long been used as a road bridge to a private house. Several important scenes for the film Tarka the Otter were filmed underneath it.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |