Mortar (masonry) facts for kids

Mortar is like a special kind of glue that holds stones and bricks together in buildings and walls. When it's first used, it's a soft paste. Some types of mortar simply dry to become strong, while others need a chemical reaction to harden. Some mortars can even resist fire for a while! People first started using mortar a very long time ago in Ancient Rome.

Contents

Ancient Mortar: Building with Early Glues

The very first mortars were made from simple materials like mud and clay. In ancient Babylonia, where there wasn't much stone but lots of clay, people built with baked bricks using lime or pitch as mortar.

Scientists believe the earliest use of mortar was around 6500 BCE in a place called Mehrgarh in Pakistan. Here, people used sun-dried bricks with a type of mortar. Later, in the Indus Valley civilization (around 3000 BCE), people used bricks that were fired in kilns (like big ovens) with a special gypsum mortar.

Gypsum mortar, also known as plaster of Paris, was used in building the famous Egyptian pyramids and many other old structures. It's made from gypsum, which doesn't need super high heat to process. This made it easier to create than other mortars and it hardened much faster. This is probably why it was popular for building arches and vaults. However, gypsum mortar isn't very strong in wet conditions.

In the early Egyptian pyramids (around 2600–2500 BCE), the huge limestone blocks were held together with mortar made of mud and clay, or clay and sand. Later, Egyptian pyramids used mortar made from either gypsum or lime. Gypsum mortar was a soft mix of plaster and sand.

In the Indian subcontinent, different types of mortar were found in Indus Valley Civilization cities like Mohenjo-daro (before 2600 BCE). A light gray gypsum cement, which included sand, clay, and a lot of lime, was used for wells, drains, and important buildings. They also used Bitumen mortar, but less often, for places like the Great Bath.

Building with concrete and mortar next appeared in Greece. Around 500 BCE, an underground water channel in Megara was coated with a special mortar called pozzolanic mortar. This type of mortar is made with lime and volcanic ash, which allows it to harden even underwater! The Greeks got this volcanic ash from islands like Thira and Nisiros. The Romans later improved how they made and used this mortar. They even developed a mortar using crushed terra cotta instead of volcanic ash, which was denser and resisted water better.

Ancient China didn't have hydraulic mortar (which hardens underwater) because they lacked volcanic ash. But around 500 CE, they found a clever solution: they mixed sticky rice soup with slaked lime to create a "sticky rice mortar." This was stronger and more water-resistant than regular lime mortar.

It's a mystery how the knowledge of making hydraulic mortar, which was so advanced in Greece and Rome, was lost for nearly 2,000 years. During the Middle Ages, when grand Gothic cathedrals were built, the only active ingredient in mortar was lime. Since lime mortar can be damaged by water, many old buildings suffered from rain over the centuries.

Modern Mortar: Portland Cement

Ordinary Portland cement mortar, often just called cement mortar, is a very common type of mortar today. It's made by mixing powdered Ordinary Portland Cement, fine sand, and water.

This type of cement was invented in 1794 by Joseph Aspdin and became very popular in the late 1800s. By 1930, it was used more than lime mortar for building. The big advantages of Portland cement are that it gets hard very quickly, which makes construction faster. Also, fewer highly skilled workers are needed to build with it.

However, Portland cement should generally not be used to fix or repoint older buildings that were originally built with lime mortar. Old buildings need the flexibility, softness, and "breathability" of lime mortar to work correctly.

In some countries like the United States, there are five standard types of mortar (M, S, N, O, K) that are sold as dry mixes. These types have different strengths based on how much cement, lime, and sand they contain. Type M is the strongest, and Type K is the weakest. The letters come from the words "MaSoN wOrK."

Special Mortars: Polymer and Firestop

Polymer Cement Mortar

Polymer cement mortars (PCMs) are made by adding polymers (like special plastics) to regular cement mortar. These polymers can be in the form of latexes or emulsions. PCMs have low permeability (meaning water doesn't easily pass through them) and help prevent cracks from drying shrinkage. They are mainly used for repairing concrete structures.

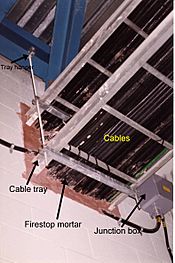

Firestop Mortar

Firestop mortars are special mortars used to block large openings in walls and floors that need to resist fire. They are part of a building's passive fire protection system. Firestop mortars have different ingredients and properties than regular mortars. You can't just use any mortar in their place because they are designed to meet specific fire safety standards.

Firestop mortar is usually a powder mixed with water that dries into a hard, stone-like material. Sometimes it's mixed with lightweight materials like perlite or vermiculite. It might also be colored so that people can easily tell it apart from regular mortar and confirm that the correct fire safety material was used.

Lime Mortar: The Breathable Choice

Lime mortar is another important type of mortar. Its setting speed can be increased by using impure limestone or by adding a pozzolanic material like calcined clay or brick dust. These additions help the mortar harden faster when mixed with water.

It's usually a bad idea to use Portland cement mortars to repair older buildings that were originally built with lime mortar. Lime mortar is softer and more flexible than cement mortar. This flexibility allows the brickwork to adjust to small movements in the ground or other changes over time. Cement mortar is much harder and doesn't allow for much flexibility. If both types are used in the same wall, the hard cement mortar can cause cracks in the brickwork.

Lime mortar is also considered "breathable." This means it allows moisture to move freely through the wall and evaporate from the surface. In old buildings, small cracks can let rainwater in. Lime mortar lets this moisture escape through evaporation, which helps keep the wall dry. If an old wall is repaired or covered with cement mortar, it can trap moisture behind the cement, leading to problems.

Pozzolanic Mortar: Hardening Underwater

Pozzolana is a fine, sandy volcanic ash. It was first found and dug up near Mount Vesuvius in Italy. The Romans discovered that adding pozzolana to lime mortar made it set relatively quickly, even underwater! Vitruvius, a Roman architect, described different types of pozzolana. Today, "pozzolana" is a general term for any material that can be added to slaked lime to create a hydraulic cement (one that hardens underwater).

When finely ground and mixed with lime, pozzolana creates a strong mortar that works like Portland cement, hardening even underwater.

Images for kids

-

Workers prepare mortar in a trough. A 10th-century sculpture from the Korogho church, Georgia.

-

Firestopped cable tray penetration. The cables and the tray are penetrants.

-

Cable tray cross barrier firestop test, full scale wall

See also

In Spanish: Mortero (construcción) para niños

In Spanish: Mortero (construcción) para niños