Coldharbour Mill Working Wool Museum facts for kids

Coldharbour Mill is a very old factory near Uffculme in Devon, England. It's one of the oldest woollen textile mills in the world. It has been making things continuously since 1797! This mill was once part of a bigger company called Fox Brothers. It's so important that English Heritage has made it a special Grade II* listed building.

Contents

Where is Coldharbour Mill?

Coldharbour Mill is easy to find, just off the M5 motorway near Uffculme. It's also close to the border with Somerset. The main office for the mill was in Wellington.

The mill was built next to the River Culm. The river's water was super important for running the machines. In 1797, Thomas Fox bought the land because of this good water supply. He said the buildings were "middling" but the "stream good."

Back then, roads were very bad. Finished cloth had to be carried by horses to ports like Topsham and Exeter. It could take twelve days to get cloth to London!

A Look at History

People believe there has been a mill here since Saxon times. The Domesday Book, a very old record, even mentions two mills in the Uffculme area.

At its busiest, the Fox Brothers company employed about 5,000 people. They owned nine mills and factories across England. One famous mill they bought was William Bliss & Sons in Chipping Norton. It was a grand mill with a reading room and even a chapel for workers.

The main factory in Wellington, called Tonedale Mills, was huge. It covered 10 acres! It was special because it made both worsted and woollen products. This meant they handled everything from raw sheep's wool to the finished cloth, all in one place.

The Fox Family Story

The Fox family, who owned the mill, were early members of the Quaker religion. In 1772, a young man named Thomas Fox joined a wool manufacturing business in Wellington. He was 25 years old.

Thomas and his wife, Sarah, built Tone Dale House in 1801. A Fox family member still lives there today! In 1826, when Thomas's sons became partners, the business changed its name to Fox Brothers.

The family was important in their local community. They even helped fund the Grand Western Canal.

Their Own Bank

In 1787, the company needed more money. So, they started printing their own "promises to pay" notes! These notes were like their own bank money and local businesses accepted them.

Later, in 1797, there was a fear of invasion, and gold became scarce. Thomas Fox printed even more notes to keep his business growing. The bank they started, Fox, Fowler and Company, grew to have over fifty branches. It was allowed to print its own bank notes until 1921.

What They Made: Textile Products

In the past, Exeter was a big center for the wool trade in England. Cloth was sent to countries like France, Holland, and Germany. A strong cloth called serge was very popular.

A writer named Celia Fiennes described the busy Exeter market in the late 1600s. She said the whole area, for about 20 miles around, was busy with spinning, weaving, and drying serges. She noted that an incredible amount of money, sometimes £15,000, was paid out in cash every week!

However, wars in Europe in the late 1700s made it hard to sell cloth. Many merchants struggled. The Fox family started making "long ells," which were fine white serge, for the East India Company.

When the East India Company's special trading rights ended in 1833, the demand for long ells dropped. Thomas Fox then focused on making flannel. Flannel was sold in England and America.

In 1881, after some army losses, the British government wanted to equip soldiers with khaki uniforms. Fox Brothers decided to make puttees, which were long strips of cloth wrapped around the lower leg. They thought this would save lives and create jobs. Fox Brothers became a major producer of puttees, making about 850 miles of the cloth during World War I!

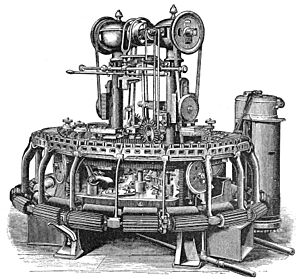

To help with flannel production, Coldharbour Mill started making worsted yarn in 1865. This needed more power for new combing machines. Worsted yarn is made from long-haired sheep's wool, and the fibers are combed to make them all straight and parallel.

The Mill's Buildings

Experts from English Heritage say Coldharbour Mill is "probably one of the best-preserved textile mill complexes in the country." It still has all the different buildings and power systems from the 1800s, plus much of the machinery from the 1900s.

Coldharbour Mill mostly made wool yarn for the weaving machines at the Wellington mill. The original mill building was likely three stories tall. The main mill building, started in 1799, was very large for its time.

The mill grew over the years. They added extensions, a stone staircase, and even a fourth floor. A special shed for combing wool was built over the water channel that carried water away from the waterwheel.

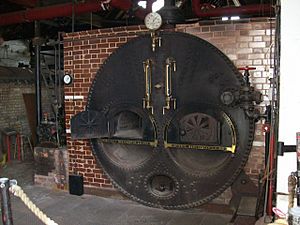

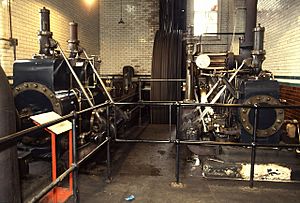

Steam power was added in three main stages. In 1865, a building for a steam engine and a boiler house were built. Later, in the 1890s and 1910, more steam engines were added, and the boiler house was made bigger.

The mill site also has many other buildings. These include stables, a carpenter's workshop, and even an air raid shelter from World War II.

How the Mill Got Its Power

Coldharbour Mill is special because it used both water and steam power for a very long time. Water power was even used for the night shift until 1978!

Water Power

The mill has a large waterwheel that is 18 feet tall and 14 feet wide. It has 48 buckets! This waterwheel is still connected to the steam engine system, which is very rare. You can often see the wheel turning today.

Steam Power

The idea of using steam engines came to the Fox family early on. Thomas Fox even invited James Watt, a famous inventor, to Wellington in 1782. However, steam engines were very expensive to run because coal was costly. Also, people were worried that machines would take their jobs.

So, the first wool spinning machines at the mill were powered by horses in 1791. It wasn't until 1865 that Coldharbour Mill got its first steam engine. By then, trains could bring cheap coal to the area.

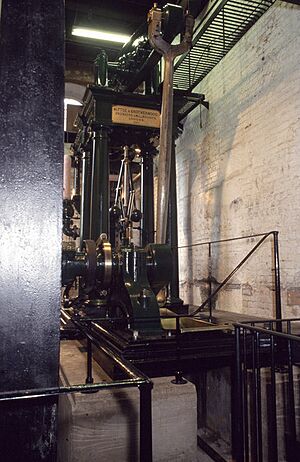

The mill has two large Lancashire boilers, but only one still works. A powerful 300 horsepower steam engine, installed in 1910, took over from earlier engines. This engine, along with the waterwheel, ran until the mill closed in 1981. Today, this big steam engine still works and runs regularly on special weekends! It uses ropes to send power to machines on all five floors.

Gas Production

Coldharbour Mill even made its own gas from coal right on site! This gas was used to light the mill, so machines could run all night. The building where they made the gas is still there today. Experts say it's a very rare example of old gas-making facilities.

Making Yarn: Textile Machinery

When Coldharbour Mill closed in 1981, all its machines were still in place. Most of these machines have been saved and are now part of the museum. Some weaving machines from the Tonedale factory were also brought here.

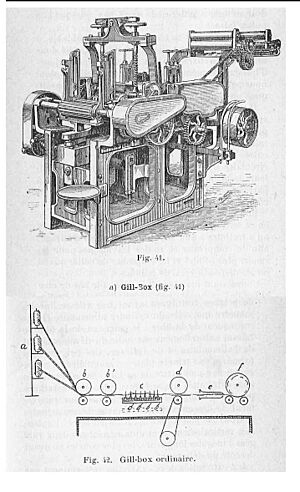

The process of making wool yarn starts with cleaning and combing the raw wool. Machines called "gill machines" open up the wool. Then, a large washer with steam-heated rollers cleans it. After washing, more gill boxes comb the fibers even more. A special "Noble combing machine" separates the long, good fibers from the shorter ones.

Today, the museum buys British wool that has already been combed and dyed. Up to ten strands of this wool are fed into an "Intersecting Gill Box." This machine starts to pull out the fibers and can blend colors to make new shades. The output is called a "sliver." This machine makes sure the sliver is always the same weight, which is important for making yarn that's not too thick or too thin.

Next, the slivers are pulled out even more and given a small twist. This makes them stronger so they can be wound onto a bobbin. At Coldharbour Mill, you can see this happening on old "draw boxes." The thread is pulled out to be much thinner and given a light twist. This creates "roving" for thick yarns like Aran yarn, or it goes through more steps for thinner yarns like double knitting yarn.

Coldharbour Mill Today

Today, Coldharbour Mill is a museum run by a charity. It's called "a working wool museum" because it still runs its old machines to show how wool products were made. You can even buy the things they make, like worsted yarn, tartan cloth, and rugs! The mill has four official tartans, including "Devon Original" and "Somerset."

The museum also has other cool exhibits:

- A World War II display.

- Lots of information about how puttees were made.

- An archive about old buses and transport from the West Country.

- Special visiting exhibitions.

| Frances Mary Albrier |

| Whitney Young |

| Muhammad Ali |