Fischer-Tropsch process facts for kids

The Fischer–Tropsch process (often called F-T) is a special set of chemical reactions. It takes a mix of two gases, carbon monoxide and hydrogen, and turns them into liquid fuels like gasoline or kerosene. Think of it like a chemical recipe that changes gases into useful liquids!

Contents

How the Process Works

The Fischer–Tropsch process involves many chemical reactions. The main goal is to create chemicals called alkanes, which are the building blocks of fuels. Sometimes, the process also makes methane gas (which is natural gas) or small amounts of different kinds of alcohol.

Making the Right Gases

Before the F-T process can even start, the gases need to be prepared. For example, any sulfur must be completely removed from the chemicals. Sulfur can cause big problems for the process.

If a factory starts with methane (natural gas) and wants to make liquid fuel, it uses a reaction called "steam reforming." This reaction changes methane into the carbon monoxide (CO) and hydrogen (H2) gases needed for F-T.

Here's how steam reforming works: H2O + CH4 → CO + 3 H2

This means one molecule of steam (H2O) and one molecule of methane (CH4) turn into one molecule of carbon monoxide (CO) and three molecules of hydrogen (H2).

Special Helpers: Fischer-Tropsch Catalysts

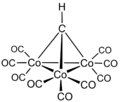

A catalyst is a substance that helps a chemical reaction happen faster without being used up itself. Many different catalysts can be used for the Fischer–Tropsch process.

The most common catalysts are metals like cobalt, iron, and ruthenium. These are all transition metals. Another metal, nickel, can also be used, but it often creates a lot of unwanted methane gas.

- Cobalt is a very active catalyst. It works best when the starting gas is natural gas.

- Iron catalysts are better when the starting gas is not as pure, like gas made from coal or biomass (materials from plants and animals).

Most metal catalysts, like cobalt and nickel, stay in their original metal form during the process. However, iron catalysts can change their form and chemical makeup during the reaction. It's important to control these changes for the process to work correctly.

Fischer-Tropsch catalysts are very sensitive to sulfur. Even a tiny amount of sulfur can mess up the reaction. Cobalt catalysts are even more sensitive to sulfur than iron catalysts.

Hot or Not? HTFT and LTFT

There are two main types of Fischer–Tropsch processes, based on temperature:

- High-Temperature Fischer–Tropsch (HTFT) happens at very hot temperatures, around 330°C to 350°C. It uses an iron-based catalyst. Companies like Sasol use HTFT in plants that turn coal into liquid fuels.

- Low-Temperature Fischer–Tropsch (LTFT) happens at lower temperatures. It uses a cobalt-based catalyst. Shell uses LTFT in a plant in Malaysia that turns natural gas into liquid fuels.

Turning Solids into Gas (Gasification)

Some F-T factories start with solid materials like coal or biomass. Before these solids can be used in the F-T process, they must be turned into gases like carbon monoxide and hydrogen. This process is called gasification.

Gasification can be a messy and expensive process. Factories that use coal for the Fischer–Tropsch process first gasify the coal. This can produce a lot of carbon dioxide (CO2). One reason for using coal is that gasification needs a lot of energy, and coal is a good source of that energy.

A Look Back: History of F-T

The original Fischer–Tropsch process was invented by two German scientists, Franz Fischer and Hans Tropsch, in the 1920s. They worked at the Kaiser Wilhelm Institute. Since then, many improvements have been made, and "Fischer–Tropsch" now refers to many similar processes.

Fischer and Tropsch got several patents for their invention. One important patent was granted to factories in Germany in 1936. At that time, Germany had a lot of coal but not much oil. The F-T process allowed them to turn coal into gasoline, which was very important for cars, airplanes, and trucks.

During World War II, the F-T process helped Nazi Germany and Japan make substitute fuels for their vehicles. About 9% of Germany's wartime fuel and 25% of its car fuel came from F-T production.

After the war, the United States Bureau of Mines started a program to study synthetic fuels. They even hired German scientists to work at a Fischer–Tropsch plant in Louisiana, Missouri, in 1946.

F-T in Business

Many big companies have used the F-T process, but it can be expensive. The equipment is costly, and running and maintaining the factories is also expensive. Also, the price of regular petroleum (oil) can change a lot, which makes it hard for F-T products to compete.

F-T factories are usually most profitable when they can use "stranded gas." This is natural gas found in places far from major cities, where it's too expensive to pipe the gas to customers. Instead, companies can turn this "stranded gas" into liquid fuels on-site, which are easier to transport and sell.

Sasol: A Big Player

The largest F-T factories in the world are run by a company called Sasol in South Africa. South Africa has a lot of coal but not enough oil. Sasol uses both coal and natural gas in the F-T process. They make many different oil substitutes and produce most of South Africa's diesel fuel.

Shell's Diesel and Wax

One of the biggest uses of F-T technology is at a Shell factory in Bintulu, Malaysia. This factory turns natural gas into low-sulfur diesel fuels and even wax used in food. It produces about 12,000 barrels of fuel each day.

In 2006, a Finnish company called UPM, which makes paper and pulp, announced plans to make biodiesel using the Fischer–Tropsch process. They planned to use waste materials from their paper and pulp factories as raw material for the biodiesel.

New Ideas: Research and Development

Using Carbon Dioxide Again

Scientists are also looking into new ways to use the Fischer–Tropsch process. In 2009, chemists for the U.S. Navy studied how to make fuels using hydrogen from seawater. They found that using an iron catalyst (instead of the usual cobalt) produced less methane and more useful short-chain hydrocarbons, which could be refined into jet fuel.

Scientists are interested in using carbon dioxide (CO2) from seawater as a source for fuel. While CO2 is only a small part of the air, ocean water contains much more of it. This makes seawater look like a good possible source for making alternative fuels.

Images for kids

-

A SASOL gas station in Gauteng, South Africa.

See also

In Spanish: Proceso Fischer-Tropsch para niños

In Spanish: Proceso Fischer-Tropsch para niños

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |