Indiana Glass Company facts for kids

|

|

| Private company | |

| Industry | Glassware |

| Founded | 1907 in Dunkirk, Indiana |

| Founder | Frank Merry |

| Defunct | 2002 |

| Headquarters | |

|

Key people

|

Frank W. Merry, Charles L. Gaunt |

| Products | pressed and blown glassware including lamp fonts, lamps and tableware |

|

Number of employees

|

1,300+ (1979) |

The Indiana Glass Company was an American company that made glass products for nearly 100 years. They created many types of glassware and tableware, including items that were pressed, blown, or shaped by hand.

The company's story began in Dunkirk, Indiana, where earlier glass factories operated as early as 1896. The Indiana Glass Company officially started in 1907. A group of investors, led by Frank W. Merry, bought a glass plant in Dunkirk. This plant used to belong to the National Glass Company, a large group of glass factories that faced financial problems.

Indiana Glass Company was known for making tableware, lamps, and vases. They also produced special types of glass collected today, like Depression glass, Goofus glass, and Carnival glass. One famous customer was A&W, the drive-in chain. Indiana Glass was the first company to make the root beer mugs for A&W. They also supplied many products to Kmart.

In 1957, another company called Lancaster Lens Company bought a major part of Indiana Glass. Lancaster Lens later changed its name to Lancaster Glass Company. By the 1960s, Indiana Glass became a part of a bigger company called Lancaster Colony Corporation. Sales grew in the 1970s, and Indiana Glass products were sold directly to homes through a program called Tiara Exclusives. The Dunkirk plant closed in 2002. Even though another plant in Oklahoma kept the Indiana Glass name for a while, it was sold to a different glass company in 2007.

Contents

How the Company Started

The Indiana Gas Boom

In the late 1880s, a big discovery of natural gas caused a huge economic growth in East Central Indiana. Gas was first found in Delaware County and Jay County. Many factories moved to this area because the gas was a cheap fuel source. For example, in Jay County, only 210 people worked in manufacturing in 1880. By 1900, over 1,423 people worked in factories, mostly glass factories. East Central Indiana became a major manufacturing hub in the state.

Beatty-Brady Glass Company

In 1895, the Pennsylvania Railroad built a large building in Dunkirk, Indiana. In 1896, George Beatty and James Brady bought this building. They started the Beatty-Brady Glass Company. By 1900, this glass factory had 225 employees and made tableware.

Around the late 1800s, many glass factories in the United States faced financial difficulties. The economy was tough, and there were several periods when business slowed down. The Beatty-Brady Glass Company also faced its own challenges during this time.

National Glass Company

In November 1899, the Beatty-Brady Glass Company was sold to the National Glass Company. This was a large group of glass tableware factories, sometimes called a "trust." It started with 11 companies and quickly grew to 19.

However, the National Glass Company also ran into financial trouble by 1903. Many of its factories closed or were destroyed by fire. By the end of 1904, most of its remaining plants were not operating.

To try and fix their problems, National Glass decided to lease some of its plants to other companies. In January 1904, Frank W. Merry leased the Dunkirk plant (the old Beatty-Brady factory). He started a new company called Indiana Glass Company. This new company had $125,000 in capital, which was a lot of money back then. Frank Merry became its president.

The Official Beginning

There's some confusion about the exact start date for the Indiana Glass Company in Dunkirk. Frank W. Merry played a key role in forming the company in 1904 when he leased the plant. In 1904, the Indiana Department of Inspection listed Indiana Glass Company as having 256 employees, making "pressed and blown glass."

However, most sources agree that 1907 is the official start date for the company. In 1907, the National Glass Company went bankrupt. Frank Merry and his partners formed a new company to buy the Dunkirk glass plant permanently. The purchase was finalized in 1909, and Frank Merry remained president.

Important people in the company's early management included Frank Merry, Henry J. Batsch, Harold H. Phillips, Charles W. Smalley, Rathburn Fuller, and James E. Merry. In 1916, Charles L. Gaunt joined as secretary and treasurer.

Early Operations

Glass factories in Dunkirk first used natural gas to heat their furnaces. But by 1905, the natural gas in the area started to run out. Indiana Glass then switched to using coal gas, which they made from coal brought in from West Virginia and Kentucky. Dunkirk's railroad line helped transport the coal and other raw materials like sand, soda ash, and lime needed for making glass.

By 1916, Indiana Glass was operating at full capacity. They added new machines, like the Daubenspeck automatic tumbler machine. This machine could take exact amounts of melted glass and put it into molds. This helped them make products like tumblers faster and with more consistent sizes.

In the early 1920s, the plant employed about 550 people when it was running at full speed. They could produce three carloads of glass products every day. The company made "pressed table glassware and lamps" and also "decorated glassware." They had showrooms in major cities like New York, Chicago, and San Francisco.

A well-known customer was the A&W Root Beer chain. Indiana Glass made the glass mugs used to serve A&W Root Beer for many years. The company made tableware by pressing melted glass into molds. Vases and lamps were made by glassblowers. In 1931, Frank Merry passed away, and Charles L. Gaunt became the company president.

During World War II, glass factories shifted to making less home glassware and more items for the war effort, such as lenses for aircraft and vehicles. After the war, tableware production restarted, but demand was lower. In 1953, Indiana Glass bought a major part of the Sneath Glass Company. This allowed them to use Sneath's special recipe for heat-resistant glass, adding to their wide range of products. At that time, Indiana Glass was a leader in barware, stemware, decorative crystal, and unique glass items.

How Molded Glassware is Made

Glass starts as a mix of ingredients like sand, soda, and lime. These ingredients are heated in a furnace to over 3,000°F (1,650°C). This intense heat melts the ingredients into a liquid, called molten glass.

For glass that is blown into a mold, a glassblower (either a person or a machine) takes a small blob of molten glass. This blob is then blown into a mold, which shapes the glass. For machine-made pressed glass, the molten glass goes to a machine that drops a precise amount into a mold. The mold then moves away, and the glass cools down.

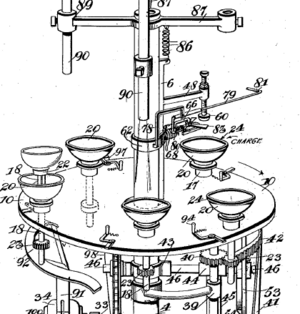

In 1916, Benjamin F. Gift in Dunkirk received a patent for a better glassware-making machine. This machine could receive molten glass, move the mold for cooling, and then release the finished glass item.

After the glass comes out of the mold, it's still hot. It's placed on a "lehr," which is a long conveyor belt inside a special oven. The glass slowly cools down in the lehr. This slow cooling process, called annealing, is very important. It stops the glass from cracking or becoming too fragile. At the end of the lehr, workers pack the cooled glass for shipping.

Products

Indiana Glass Company made many different glass patterns. They were a major producer of what collectors call Depression Glass. They also made Goofus glass, which was inexpensive glass with painted designs. Another type of low-cost glass they made was Carnival glass.

In 1919, Indiana Glass started making a 10-ounce beer mug. This mug became famous because A&W used it for root beer at their stands. In the early 1920s, Indiana Glass also introduced a smaller, child-sized mug that held 3.5 ounces, also for A&W.

Some of their well-known Depression Glass patterns include Avocado, Indiana Custard, Pyramid, Sandwich, and Tea Room.

- Avocado is the collector's name for Indiana Glass pattern number 601. It was made from 1923 to 1933 in clear, green, and pink colors. The design looks more like a pear than an avocado, so it's sometimes called Sweet Pear. This pattern was brought back in the 1970s through the 1990s for products sold by Tiara Exclusives, using 15 new colors.

- Indiana Custard is the collector's name for the Flower and Leaf Band pattern. It was made from the 1930s to the 1950s. This pattern was used for coffee sets in an opaque, custard-colored glass with decorative bands. A version made from milk glass was called Orange Blossom.

- Pyramid is the collector's name for Indiana Glass pattern number 610. This pattern was made from 1926 to 1932. It had sharp, angular designs that were considered modern for the late 1920s, when most pressed glass featured floral patterns. While originally made for commercial use, it was also used in homes. In 1974 and 1975, reproductions were made in black and blue glass for Tiara Exclusives.

- The Sandwich pattern (Indiana Glass version) was made from the 1920s through the 1980s. The color of the glass can sometimes help guess when it was made. Tiara Exclusives was still selling the Sandwich pattern in 1980.

- Tea Room was another pattern designed for commercial use, but also popular in homes. Like Pyramid, it had a modern, angular design for the late 1920s. It was sold for use in tea rooms, ice cream parlors, and soda fountains. Tea Room was only made from 1926 to 1931. Its art deco look makes it popular with collectors today. The Tea Room dinner sets came in clear, amber, green, and pink glass.

Lancaster Colony Corporation

In 1957, Lancaster Lens Corporation bought a controlling share of Indiana Glass. Robert K. Fox, the president of Lancaster Lens, became president of both companies. A month later, Lancaster Lens changed its name to Lancaster Glass Corporation.

In 1961, Lancaster Colony Corporation was formed as a holding company. By 1963, Lancaster Colony owned several companies, including Indiana Glass, Lancaster Glass, and Bischoff Glass Company.

Tiara Exclusives

Tiara Exclusives was a company owned by Lancaster Colony that started on July 1, 1970. It used a multi-level marketing approach, selling glassware made by companies like Indiana Glass through home parties, similar to how Tupperware is sold. Tiara was very successful at first, offering part-time work to many homemakers. By 1972, it had 750 sales representatives. The glassware sold through Tiara, especially from Indiana Glass, often used older, popular patterns.

Peak and Decline

Peak Years

By 1977, Indiana Glass was the fifth-largest glassware producer in the United States. They had about $36 million in sales of machine-made glassware and employed over 1,000 people at their Dunkirk factory.

At its busiest in 1979, the Dunkirk factory employed about 1,300 people. Indiana Glass also had another plant in Sapulpa, Oklahoma.

Decline

In the 1980s, cheap glassware imports became a problem for American glass companies. In 1986, Indiana Glass closed one of its Dunkirk facilities because of this competition. About 200 employees lost their jobs. The increased imports were partly due to new trade agreements. Indiana Glass, once the third-largest glassware producer, began to face financial difficulties. By the end of 1986, it employed about 600 people.

Lancaster Colony Corporation, which owned Indiana Glass, had many different businesses. Their Glass and Candles section, which included Indiana Glass, made up 27 percent of their sales in 1994. The Indiana Glass and Tiara names were important for the company. However, Tiara Exclusives was stopped in November 1998, which negatively affected sales in 1999. By 2002, the Glassware and Candles section had declining sales for three years in a row. They also faced losses when Kmart filed for bankruptcy.

Glassmaking Ends

Workers at the Indiana Glass plant in Dunkirk went on strike on October 8, 2001. The country was also experiencing a small economic slowdown at the time. The strike lasted three months. Production restarted for a short time, but it didn't last.

Lancaster Colony stopped all production at the Dunkirk factory of Indiana Glass in November 2002. About 240 workers immediately lost their jobs. The main reason for the shutdown was economic — business had been slow for the past three years. Lancaster Colony still owned another glass plant in Sapulpa, Oklahoma, which continued to operate under the Indiana Glass name for a while.

In 2006, a group called Barington Capital Group pushed Lancaster Colony to sell its glassmaking business. In November 2007, Lancaster Colony sold most of its glassmaking operations, including Indiana Glass Company, to Monomoy Capital Partners LP. These new acquisitions were then combined with Monomoy's Anchor Hocking Company.

Images for kids

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |