Peavey–Haglin Experimental Concrete Grain Elevator facts for kids

|

Peavey–Haglin Experimental Concrete Grain Elevator

|

|

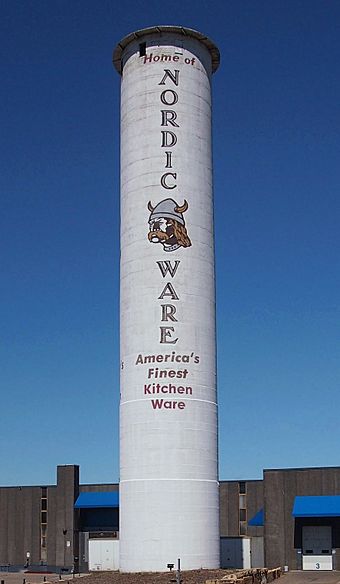

The Peavey–Haglin Experimental Concrete Grain Elevator from the southwest, now advertising Nordic Ware

|

|

| Location | 5005 County Road 25, St. Louis Park, Minnesota |

|---|---|

| Area | Less than one acre |

| Built | 1899–1900 |

| Architect | Charles F. Haglin |

| NRHP reference No. | 78001547 |

Quick facts for kids Significant dates |

|

| Added to NRHP | December 19, 1978 |

| Designated NHL | December 21, 1981 |

The Peavey–Haglin Experimental Concrete Grain Elevator is a very important building. It was the world's first known round grain elevator made from concrete. This elevator was built in St. Louis Park, Minnesota, between 1899 and 1900.

Its main purpose was to test a new idea: could concrete be used to store grain safely? Before this, most grain elevators were made of wood. Wooden elevators often caught fire or even exploded because of grain dust. The concrete design was a huge improvement.

This new round concrete design quickly became the standard for grain storage in the United States. It completely changed how grain was kept. After its first successful tests, the Peavey–Haglin Elevator was never used for storing grain again. Since the late 1960s, it has been kept by the Nordic Ware company. You can see their name and logo painted on it.

The Peavey–Haglin Elevator is recognized as a special historical site. It was added to the National Register of Historic Places in 1978. Then, in 1981, it was named a National Historic Landmark. In 1983, it became a Historic Civil Engineering Landmark.

Contents

Why a New Grain Elevator?

The "Elevator King" and Fire Risks

Frank Peavey (1850–1901) was a grain merchant from Maine. He moved to the Midwest and started a big business. He bought grain from farmers and stored it in elevators. Then, he would send it to flour mills.

By 1881, Peavey was based in Minneapolis. He became known as the "Elevator King." He owned many elevators across Minnesota, Iowa, and the Dakotas. But there was a big problem: wooden elevators were very dangerous. They were made of wood, which burns easily. They were also full of tiny grain dust, which can explode. Plus, they were often next to railroad tracks, where trains could spark fires.

Many elevator fires caused insurance costs to go way up. Peavey believed there had to be a better way. He wanted to build a large, fireproof grain elevator.

A New Idea: Reinforced Concrete

Peavey hired Charles F. Haglin (1849–1921), a local civil engineer. They worked together to solve the problem. They soon realized that reinforced concrete was a great solution. Reinforced concrete was a new invention that became popular in the 1880s. It uses steel bars inside concrete to make it stronger.

Building the First Concrete Elevator

"Peavey's Folly" Takes Shape

Other engineers thought Peavey and Haglin's idea was crazy. They said a round concrete elevator would explode when full of grain. They also thought it would crack when emptied. But Peavey and Haglin went ahead with their plan.

Construction started in the summer of 1899. People who doubted the project called it "Peavey's Folly." Haglin built a round frame, called a formwork, using steel hoops. Workers then poured concrete into this frame. After the concrete hardened, the frame was moved up to build the next section.

How it Was Built

This method allowed them to build the elevator section by section. It reached a height of 68 feet (21 m). The inside of the elevator was 20 feet (6.1 m) wide. The walls were 12 inches (30 cm) thick at the bottom. They got thinner towards the top, measuring 8 inches (20 cm) thick.

By the fall, the elevator was ready. Peavey had it filled with grain. The structure held strong. The grain was left inside to see how it would survive the winter.

Checking Out European Designs

A Trip Across the Ocean

While they waited for the winter test results, Peavey sent Haglin to Europe. Haglin's job was to see if anyone there had built reinforced concrete elevators. His young son Eddie and Peavey's son-in-law Frank Heffelfinger went with him.

From January to March 1900, they traveled a lot. They visited grain facilities and met experts in many cities. These included London, Hamburg, Copenhagen, Budapest, and Paris.

What They Found

They did find some concrete elevators in Europe. However, all of them were square or hexagonal, not round. Most were also built on top of steel or wood bins. Others were made of brick or stone with mortar.

When Haglin returned to Minneapolis, he reported his findings. He told Peavey that Europeans were not ahead of Americans in this type of construction.

A Huge Success and Lasting Impact

The Big Test Day

In the spring of 1900, it was time to empty the experimental elevator. A crowd gathered to watch. Many people stood far away, still expecting something bad to happen. But Haglin trusted his design. He stood right at the bottom of the elevator. He pulled the lever, and the grain poured out into a pit next to it.

The elevator stayed perfectly strong. The crowd started cheering! It was a huge success.

Changing the Industry

After this, Haglin made the elevator even taller, reaching 125 feet (38 m). He did a few more tests, which also worked perfectly. After these tests, the prototype elevator was never used to store grain again.

Peavey immediately asked Haglin to build a large grain elevator complex in Duluth. News of Peavey and Haglin's round concrete design spread quickly. It was soon adopted all over the American Midwest.

While traditional wooden elevators were still used on farms, the new concrete design appeared at major shipping centers. This completely changed the grain storage industry. Grain elevators, often the tallest buildings in the flat Midwest, became a symbol of successful farming.

The Elevator's Later Years

A Sad Loss and New Owners

Sadly, Frank Peavey died unexpectedly from pneumonia on December 30, 1901. He did not live to see how much his project would change the industry.

The experimental grain elevator stood unused for many years. Different businesses came and went around it. In the 1950s, Lumber Stores, Inc. owned the property. They painted their name on the elevator.

Nordic Ware, a company famous for making kitchenware like the Bundt cake pan, started nearby in 1946. As they grew, Nordic Ware bought the land where the elevator stood.

Restoration and Recognition

In 1969, Nordic Ware found that the elevator was getting old and might collapse. They knew how important the building was to history. So, the company spent $40,000 to fix it up. Around this time, the elevator was painted with the Nordic Ware advertisement you see today.

The Peavey–Haglin Experimental Concrete Grain Elevator is still there. It stands near the busy intersection of State Highways 7 and 100. It overlooks the Nordic Ware factory, the Cedar Lake Trail, and Lilac Park.

| Charles R. Drew |

| Benjamin Banneker |

| Jane C. Wright |

| Roger Arliner Young |