Saturn V dynamic test vehicle facts for kids

|

Saturn V dynamic test vehicle

|

|

The first stage of this Saturn V is hoisted into position for a shake test at the Saturn V dynamic test stand in 1966.

|

|

| Location | Huntsville, Alabama |

|---|---|

| Built | 1964 |

| Architect | NASA-Marshall Space Flight Center; Boeing Aircraft |

| NRHP reference No. | 78000500 |

Quick facts for kids Significant dates |

|

| Added to NRHP | November 22, 1978 |

| Designated NHL | February 10, 1987 |

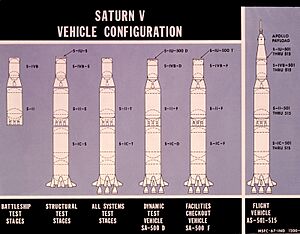

The Saturn V dynamic test vehicle, also known as SA-500D, was a special prototype of the Saturn V rocket. NASA used it to test how the rocket would handle strong shaking during launch. It was the first full-sized Saturn V rocket ever put together by the Marshall Space Flight Center (MSFC).

Even though SA-500D never flew into space, it was super important. It helped engineers develop the real Saturn V rockets that took the first astronauts to the Moon as part of the Apollo program. This test rocket was built under the guidance of Dr. Wernher von Braun. It helped test all the equipment and facilities needed for the Saturn V at MSFC.

SA-500D is the only Saturn V rocket on display that was actually used for its original purpose. It's also the only one that was put together before being moved to a museum. You can see it today at the U.S. Space & Rocket Center in Huntsville, Alabama.

Contents

Why Test Rockets?

Before a Saturn V rocket could launch, engineers had to be sure it was safe. They needed to check if the design could handle everything from being built to flying to the Moon. To do this, they created five different test versions of the Saturn V.

These test versions went through many simulations. They tested everything the rocket would experience during launch and flight. All these tests had to pass before the Marshall Space Flight Center would say the Saturn V was ready to fly.

SA-500D was one of these five test versions. Its main job was to show how the Saturn V would bend and vibrate. It also helped check if the guidance and control systems would work correctly. The rocket's powerful engines created huge amounts of shaking. Engineers needed to make sure the rocket wouldn't break apart or go off course from these vibrations.

Other test versions included:

- Battleship test model: Used for early engine firing tests and design improvements.

- Structural test model: Checked if the rocket's structure was strong enough for launch.

- SA-500F: Used to test launch facilities and train the launch crews.

- SA-500T: Tested all the rocket's systems together by firing the engines.

SA-500D did not have a real Apollo spacecraft on top. Instead, it used "boilerplate" parts. These parts had the same size, shape, and weight as the real spacecraft. They helped test the entire rocket system.

Building the Test Rocket

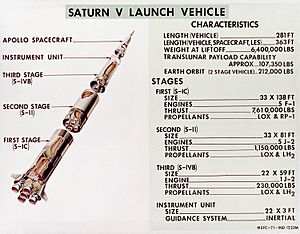

The Saturn V rocket had three main parts, called stages, and an Instrument Unit (IU).

- The first stage (S-IC) was super powerful. It provided a massive push to lift the rocket to about 200,000 feet (61 km) high. Then, it would fall away into the Atlantic Ocean.

- The second stage (S-II) took over, pushing the rocket almost into Earth orbit.

- The third stage (S-IVB) gave the final push to reach orbit. It also performed a special burn to send the Apollo spacecraft toward the Moon.

- The Instrument Unit (IU) was the rocket's brain. It was a computer that guided and controlled the rocket.

SA-500D was the complete assembly of these parts for dynamic testing. The Saturn V dynamic test stand was a huge structure with special "electrodynamic shakers." It could hold the entire Saturn V rocket and shake it. This shaking copied the vibrations that the rocket engines would create during a real launch.

The parts for SA-500D were built between 1964 and 1966. The actual tests happened in 1966 and 1967. Some parts of SA-500D were first used for testing the Saturn IB rocket. This was because the Saturn V shared some parts with the Saturn IB.

Engineers at MSFC named each stage with a suffix to show its purpose. For example, S-IC-D meant it was the first stage (S-IC) for dynamic testing. S-IC-1 was the first flight model of the first stage.

Here's how each part of the SA-500D test rocket came together:

Apollo Boilerplate

Building the test rocket started from the top. A "boilerplate" Apollo spacecraft, called BP-27, was used for all dynamic tests. Boilerplate parts are test versions that look and weigh like the real thing. They don't need to be fully working spacecraft. BP-27 had many sensors to record data for engineers to study.

BP-27 was made of special test hardware. It included a command module and launch escape system built just for it. Other parts, like the service module (SM-010) and the spacecraft–lunar module adapter (SLA #1), were also assigned to BP-27.

The Marshall Space Flight Center received BP-27 in late September 1964. Soon after, they got the boilerplate lunar module, called LTA-2. Interestingly, LTA-2 is the only part of SA-500D that actually flew in space! It was fixed up, renamed LTA-2R, and flew on the Apollo 6 mission.

BP-27 was first used for Saturn IB dynamic testing. Then it went to Kennedy Space Center for another test rocket (SA-500F). Finally, it came back to MSFC for the full Saturn V tests with SA-500D.

Third Stage

The third stage, S-IVB-D, arrived at MSFC before any other Saturn V stages. This was because it was first used for dynamic testing with the Saturn IB rocket. It was built by Douglas near Los Angeles.

It traveled by barge through the Panama Canal and several rivers. It arrived at MSFC on January 4, 1965. On the same day, the first stage of the Saturn IB (S-IB-D/F) also arrived. These parts were put together with the Instrument Unit (S-IU-200D/500D) and BP-27. They were used for Saturn IB dynamic tests from February to September 1965. After that, it was used for the Saturn V tests.

Instrument Unit

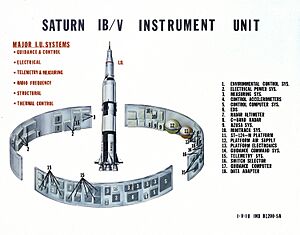

The Saturn V instrument unit was like the electronic brain for the rocket's first three stages. It controlled the engines, guidance, stage separation, and even the temperature inside the rocket. It had a strong ring for structure and electronics inside.

The Instrument Units had a slightly different naming system. S-IU-200D/500D was made for both the SA-200D (a Saturn IB) and SA-500D (the Saturn V).

IBM built the electronics for the IU. They even built a special facility in Huntsville with a clean room for this work. The IU's structural ring had two jobs: holding IBM's electronics and supporting everything above it. It had to be strong enough to hold the weight of the lunar module, service module, command module, and three astronauts.

The IU for SA-500D was the second one built. Its ring was finished in January 1965, and IBM installed the electronics by February 1. It was the last piece needed for the Saturn IB dynamic testing program. It was stacked with S-IVB-D, S-IB-D, and BP-27 for most of 1965. On October 8, 1965, it began dynamic testing for the Saturn V program as part of SA-500D.

First Stage

The Marshall Space Flight Center built the first few test and flight versions of the S-IC first stage. S-IC-D was the first one built by Boeing at the Michoud Assembly Facility in New Orleans. Boeing used the tools developed in Huntsville for this.

On September 9, 1965, Hurricane Betsy hit the Michoud Assembly Facility. The building holding S-IC-D was badly damaged, but the stage itself was quickly repaired.

S-IC-D made the first trip on NASA's barge Poseidon. It arrived at MSFC on October 13, 1965. The huge first stage was lifted into the dynamic test stand on January 13, 1966. An observer said, "Fog and clouds hovered around the top of the 360 foot (110 m) tall test stand most of the day while the 300,000 pounds (140,000 kg) stage was being lifted from its transporter into place inside the stand, said to be the tallest building in Alabama."

Second Stage

The second stage of SA-500D had a complicated journey. The original second stage planned for dynamic testing (S-II-D) was canceled. Instead, engineers decided to use another test article that had a different main purpose. Two of these test articles were damaged during other tests. The one finally used in SA-500D was named S-II-F/D.

S-II-F was a facilities checkout article. It was shipped from Seal Beach, California to Kennedy Space Center on February 20, 1966. There, it became part of SA-500F, which checked out the facilities for preparing the Saturn V. SA-500F was put together in the Vehicle Assembly Building (VAB). It was then rolled out to the launch pad on May 25, 1966.

After the facilities checkout at KSC was done, the parts of SA-500F were sent to MSFC to become part of SA-500D. This included the Apollo boilerplate BP-27 and the S-II-F/D. The second stage was changed for dynamic testing. It was shipped by the Poseidon barge from KSC on October 29, arriving at MSFC on November 10, 1966.

How Dynamic Testing Worked

Engineers needed to know exactly how the rocket would move and shake during flight. This information was vital for designing the rocket's structure, guidance, and control systems. The dynamic test project helped them find these characteristics and confirm their earlier calculations.

The main goals of these dynamic tests were to:

- Find out how the rocket's structure would move and shake in conditions like flight.

- Figure out the best places for sensors and how the control system would react.

- Make sure all the rocket stages and parts fit together correctly.

- Compare test results with actual flight results to improve future rocket designs.

- See how the rocket would move when being transported from the Vehicle Assembly Building to the launch pad.

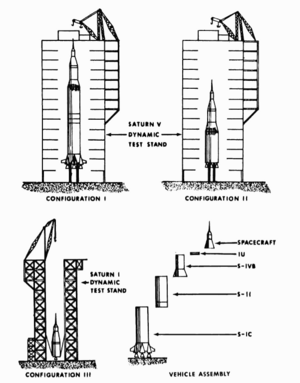

Dynamic tests were done in three different setups, each for a different phase of Saturn V flight.

- Configuration I tested the entire rocket stack, like it had just launched.

- Configuration II tested the rocket after the first stage had fallen away and the second stage was firing.

- Configuration III tested just the third stage and the Apollo spacecraft.

Configuration III tests happened in late 1965. They used the Saturn IB dynamic test facility. This was while the Saturn V test stand and the first and second stages were still being built.

Configuration I tests needed the Saturn V's first stage. It was loaded into the test stand on January 13, 1966. But testing had to wait for the last piece, the second stage, to arrive.

By November 10, 1966, all the parts were at MSFC. The second stage was stacked on top of the first on November 23. The third stage was added on November 30. The Instrument Unit and boilerplate Apollo were installed in December. The rocket was now ready for "Configuration One" testing.

Configuration One tests ran from January through March 1967. These tests found "several minor irregularities" that needed fixing. These issues were addressed during March 1967.

Configuration Two testing followed. For this, the first stage was removed from the stack. This simulated conditions after the first stage had separated during flight.

During testing, engineers looked at how the rocket reacted to shaking from side-to-side, up-and-down, and twisting. The rocket sat on a special support system that allowed it to move freely. Engineers tested vibrations with different amounts of "fuel" (ballast) to copy different moments in the flight.

NASA historian Mike Wright explained the testing: "The tests involved 450 hours of shaking. They gathered data from about 800 measuring points. A fake Apollo capsule, with the same weight and center of gravity as the real one, was placed on top of the rocket. Forces were applied to the rocket's tail to simulate engine thrust. Other flight factors were also added to test reactions. During some shaking tests, the top of the rocket moved as much as 6 inches. The bottom moved up to 3 inches. These tests were required before the Center could confirm that the guidance system would keep the rocket on course during launch."

On August 3, 1967, MSFC announced that the dynamic test program was a success. This meant the Saturn V's dynamics and structure were ready for its first launch later that year. The testing led to "several slight modifications" for the final flight rockets.

The first Saturn V launch, Apollo 4, happened three months later. The test article LTA-2 was fixed up as LTA-2R and flew on the next Saturn V launch, Apollo 6.

On Public Display

After all the tests were finished, SA-500D was put back together in Huntsville. This time, it was for public display at the Alabama Space Science Center. The rocket was moved to the museum on June 28, 1969. It was displayed lying down next to other rockets, including a Saturn I standing upright. SA-500D was installed in 1969, and the museum (later renamed) opened in 1970.

SA-500D was recognized as a List of Historic Mechanical Engineering Landmarks in 1980. It was also declared a National Historic Landmark in 1987. In 1989, the museum became known as the U.S. Space & Rocket Center.

Restoration Efforts

After many years of being outside, the rocket started to show damage from weather and pests. In 2005, the U.S. Space & Rocket Center decided to restore it. Experts found significant damage to the metal and other materials like foam and fiberglass. The full restoration of the Saturn V began in June 2005.

The restoration finished in July 2007. The Saturn V was then moved into a new building designed to protect it. This building also provides more museum space. The move took about a week, starting on July 10. The Davidson Center for Space Exploration opened in January 2008.

On May 3, 2012, someone shot three bullets at the Davidson Center from Interstate 565. The bullets broke three windows. Two bullets hit SA-500D's third stage, leaving dents and marring the paint. Luckily, no one was hurt. The damage was fixed within two months.

What's on Display?

The SA-500D display includes:

- The first stage (S-IC-D)

- The second stage (S-II-F/D)

- The third stage (S-IVB-D)

- The Instrument Unit (S-IU-200D/500D)

- A service module (SM-010)

- A spacecraft–lunar module adapter (SLA)

- A boilerplate (BP-23A)

BP-23A was used in tests to check the launch escape system and recovery parachutes. It was refurbished and used again in another test on June 29, 1965.

The dynamic test boilerplate, BP-27, is also on display at the U.S. Space and Rocket Center. It sits on top of the vertical Saturn I rocket.

Other Apollo and Saturn items you can see there include the Apollo 16 command module, the Apollo 12 Mobile Quarantine Facility, a Lunar Lander, and another Instrument Unit.

Images for kids

-

The first stage of this Saturn V is hoisted into position for a shake test at the Saturn V dynamic test stand in 1966.

-

Wernher von Braun gives a sense of scale to the F-1 engines of the S-IC first stage as he stands at the base of SA-500D on display.

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |