Tunnel boring machine facts for kids

A tunnel boring machine (TBM) is a giant machine used to dig tunnels. People sometimes call them "moles" or "worms" because of how they dig through the ground. These machines can dig through many different types of ground, like hard rock, wet or dry soil, and sand. Each type of ground needs a special kind of TBM.

TBMs are a different way to dig tunnels compared to using drilling and blasting (D&B) methods, which involve explosives, or digging by hand.

Using TBMs causes less disturbance to the ground around the tunnel. They also create a very smooth tunnel wall. This means it costs less to finish the inside of the tunnel. TBMs are great for digging tunnels in cities because they don't shake the ground as much. However, these machines are expensive to build. The really big ones can also be hard to move around. But for very long tunnels, these costs become less of a problem.

Tunnels dug by TBMs can be from about 1 meter (3 feet) to 17.6 meters (58 feet) wide. Smaller tunnels are usually made using other methods. TBM tunnels are usually round. But they can also be U-shaped, horseshoe-shaped, square, or rectangular.

The speed of digging tunnels has gotten much faster over time. The first TBMs could only dig about 4 meters (13 feet) per week. Forty years later, this increased to 16 meters (52 feet) per week. By the end of the 1800s, speeds reached over 30 meters (98 feet) per week. Today, rock TBMs can dig over 700 meters (2,300 feet) per week! Machines that dig through soil can go even faster, over 200 meters (650 feet) per week. Generally, the bigger the tunnel, the slower the digging speed.

History of Tunnel Boring Machines

Early Ideas (1800s)

The first successful idea for a "tunnelling shield" was created by Sir Marc Isambard Brunel in 1825. He used it to dig the Thames Tunnel in London. This was just the shield idea, though. The actual digging was still done by hand.

The first machine built to bore a tunnel was called the Mountain Slicer. It was ordered by the King of Sardinia in 1845. This machine was meant to dig the Fréjus Rail Tunnel through the Alps between France and Italy. It had over 100 drills on its front. But money problems stopped the project. The tunnel was finished later using simpler tools.

In the United States, the first boring machine was used in 1853 for the Hoosac Tunnel. It was called Wilson's Patented Stone-Cutting Machine. It used special cutting discs, like those on a farm tool, to break the rock. This was a new way to remove rock, using pressure instead of chiseling or blasting.

Later in the 1800s, British officers Major Frederick Beaumont and Major Thomas English improved TBMs. In 1875, a trial run for a tunnel under the English Channel used English's TBM. It dug through chalk for about 1,840 meters (6,036 feet). A French engineer, Alexandre Lavalley, used a similar machine to dig from the French side. But the Channel Tunnel project was stopped because the British military worried it could be used for invasion.

Even so, in 1883, this TBM was used to dig a railway ventilation tunnel. This tunnel was 2.1 meters (7 feet) wide and 2 kilometers (6,750 feet) long. It went under the River Mersey between Birkenhead and Liverpool, England.

The Hudson River Tunnel was built using a Greathead shield TBM. Compressed air was used to help prevent cave-ins. However, many challenges were faced during its construction.

1900s and 2000s

In the late 1800s and early 1900s, people kept designing and testing TBMs. They tried machines with rotating drills, hammers, or even giant teeth. But these early TBMs were often too expensive or couldn't dig through hard rock. So, interest in them went down. However, TBMs continued to be developed for softer rock, like in potash and coal mines.

A very large TBM, 14.4 meters (47 feet) wide, was made for Canada's Niagara Tunnel Project. This machine was used to dig a hydroelectric tunnel under Niagara Falls. It was nicknamed "Big Becky."

In 2013, a huge TBM called Bertha was built. It was 17.45 meters (57 feet) wide. Bertha was used for the Highway 99 tunnel project in Seattle, Washington. It started digging in July 2013 but stopped in December 2013 for major repairs. Bertha finished the tunnel on April 4, 2017.

Two TBMs were used for Kuala Lumpur's Rapid Transit system. They dug through sandy mudstone and other soft ground. They could dig over 345 meters (1,130 feet) per month!

The world's largest hard rock TBM is called Martina. It can dig a tunnel 15.62 meters (51 feet) wide. It is 130 meters (426 feet) long and weighs 4,500 tons! Martina was used for the Sparvo gallery of the Italian Motorway Pass A1. The same company also built the world's largest slurry TBM, which digs tunnels 17.6 meters (58 feet) wide.

Types of Tunnel Boring Machines

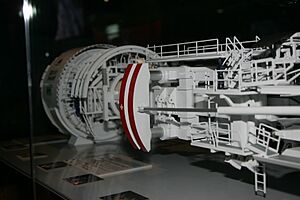

TBMs usually have a spinning cutting wheel at the front, called a cutter head. Behind it are other important parts. These include a main bearing, a system to push the machine forward, a way to remove the dug-out material (called muck), and support systems. Machines are designed differently depending on the type of ground, how much water is present, and other things.

Machines that dig through hard rock are different from those that dig through soft earth. They cut differently, push differently, and support the tunnel walls differently.

Tunnel Wall Types

Concrete Lining

Shielded TBMs are often used to dig tunnels in soft soil. They put up concrete segments behind the machine to support the tunnel walls.

The machine pushes against these concrete segments with strong hydraulic cylinders. This allows the TBM to apply force to the front of the tunnel as it digs.

Main Beam

Main Beam machines do not put up concrete segments right behind the cutter head. Instead, they use other ways to support the rock. These can include metal rings, rock bolts, or sprayed concrete (shotcrete).

Shield Types

The walls of a newly dug tunnel often need support right away to stop them from collapsing. Many TBMs have one or more cylindrical shields that follow the cutter head. These shields support the walls until permanent tunnel supports are built. The stability of the walls also affects how the TBM pushes itself forward.

Open/Gripper

Gripper TBMs are used in rock tunnels. They don't use a shield. Instead, they push directly against the unreinforced sides of the tunnel.

Some gripper machines can only move forward when they are not gripping the tunnel walls. Others can move continuously.

Single Shield

A single-shield TBM has one cylindrical shield behind the cutting head. A permanent concrete lining is built right after this shield. The TBM then pushes off this new lining to apply force to the cutter head. Because it has to push off the lining, a single-shield TBM digs and builds the lining in separate steps.

Double Shield

Double Shield TBMs have two shields. A front shield moves with the cutting head. A back shield acts as a gripper. The two shields can move in and out like a telescope. The gripper shield holds the TBM in place. This allows the machine to push the cutter head forward while also building the concrete lining at the same time.

Tunnel-Face Support Methods

In hard rock with little water, the area around the TBM's cutter head can be left open. The rock face can support itself. But in weaker soil, or when there's a lot of water, pressure must be applied to the front of the tunnel. This stops it from collapsing or letting water into the machine.

Earth Pressure Balance Machine (EPB)

]]

Earth Pressure Balance (EPB) machines are used in soft ground with low pressure. They use the dug-out material (muck) to keep pressure at the tunnel face. The muck enters the TBM through a special screw. By controlling how fast the muck is removed and how fast the TBM moves, the pressure at the front can be controlled. Sometimes, things like foam or special liquids are added to the ground to make it more stable.

EPB machines push forward by pressing against the concrete segments they install. Their cutter heads have different types of cutting tools for digging.

EPB machines have made it possible to dig through soft, wet, or unstable ground much faster and safer than before. The Channel Tunnel, parts of the London Underground, and most new metro tunnels built in the last 20 years used this method.

Slurry Shield

Slurry shield machines are used in soft ground with high water pressure or in sandy/gravelly conditions. The cutter head is filled with pressurized slurry, usually made of bentonite clay. This slurry pushes against the tunnel face to keep it stable. The slurry mixes with the muck and is then pumped out of the tunnel to a special plant.

At the plant, the slurry is cleaned so it can be reused. Slurry TBMs are not good for very fine silts and clays because the muck particles are too small to separate from the bentonite.

Sometimes, a special sealed area is built at the cutting head so workers can operate the machine. This area might have high air pressure, so workers need special training.

Open Face Soft Ground

Open face soft ground TBMs are used when the dug-out ground can stand on its own for a short time. They are good for ground that is not too strong and doesn't have much water. They can dig tunnels over 10 meters (33 feet) wide. After digging a section, the shield is pushed forward to start a new section. The tunnel is supported by precast concrete segments. The last segment, called the key, is wedge-shaped and locks the ring tightly against the ground.

Tunnel Size

TBMs can dig tunnels from about 1 meter (3 feet) to 17 meters (56 feet) in diameter. Micro tunnel shield TBMs are used for small tunnels, usually 1 to 1.5 meters (3 to 5 feet) wide. These are too small for people to walk inside.

Backup Systems

Behind all types of tunnel boring machines, in the part of the tunnel that is already finished, there are trailing support decks. These are called the backup system. They can include conveyors to remove the muck, pipes for slurry (if used), control rooms, electrical systems, and ventilation systems. They also have ways to transport the pre-made concrete segments into place.

Urban Tunnelling

Digging tunnels in cities has a special rule: the surface above must not be disturbed. This means avoiding the ground sinking. In soft ground, this is usually done by keeping the soil pressure stable during and after digging.

TBMs that can control the pressure at the tunnel face, like Earth Pressure Balance (EPB) and Slurry Shield (SS) machines, are used for this. Both EPB and SS types can lower the risk of the surface sinking if the ground conditions are well known. When digging in cities, engineers must also think about other tunnels, existing pipes, and building foundations. The project must make sure these are not harmed.

See also

- Channel Tunnel

- New Austrian tunneling method

- Roadheader

- Subterrene

- Trenchless technology

Images for kids

| Shirley Ann Jackson |

| Garett Morgan |

| J. Ernest Wilkins Jr. |

| Elijah McCoy |