Whitbread Engine facts for kids

Quick facts for kids Whitbread Engine |

|

|---|---|

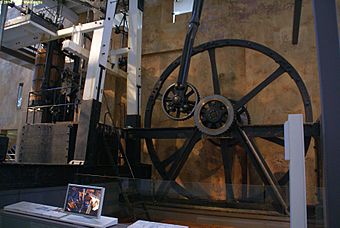

Boulton & Watt steam engine decommissioned in 1887, at the Powerhouse Museum

|

|

| Origins | |

| Type | Watt, rotative beam |

| Designer | James Watt |

| Maker | Boulton and Watt |

| Date | 1785 |

| Country of origin | England |

| Former operator | Whitbread, London, England |

| Purpose | Driving brewery machinery |

| Measurements | |

| Cylinders | 1 |

| Bore | 0.64 metres (25 in) |

| Stroke | 1.8 metres (6 ft) |

| Flywheel diameter | 4.27 metres (10 ft) |

| Power | 26 kilowatts (35 hp) (as built) |

| Preservation | |

| Location | Powerhouse Museum, Sydney, Australia 33°52′40″S 151°11′58″E / 33.877898°S 151.199573°E |

The Whitbread Engine is a super old and important machine! It's a steam engine that was built way back in 1785. You can see it today at the Powerhouse Museum in Sydney, Australia. It's special because it's one of the very first steam engines that could make things spin, and it's the oldest one still around!

This engine is a "rotative" type. That means it takes an up-and-down motion and turns it into a spinning motion. This spinning power was perfect for running machines all day long.

The famous engineer James Watt designed this engine. It was built by his company, Boulton and Watt. Its first job was at the Whitbread brewery in London, England. After working for over 100 years, it was moved to Australia in 1887. Today, it has been fixed up and can even run again!

Engine's Story

In 1784, a man named Samuel Whitbread ordered this engine. He wanted it for his brewery in London. It was meant to replace a large horse mill that horses used to power.

The engine was set up in 1785. It was only the second steam engine ever put into a brewery. With this new engine, Whitbread's brewery became the biggest in Britain! They even kept the old horse wheel as a backup, just in case the steam engine stopped working.

The engine's spinning parts were connected to wooden shafts. These shafts ran machines all over the brewery. The machines helped crush malt and lift it into hoppers. There was also a pump that moved beer and a stirrer for large vats. Another pump connected to the engine's beam pulled water from a well to a roof tank.

In 1787, something exciting happened! King George III and Queen Charlotte visited the brewery. This was great publicity for both the brewery and the engine makers. The engine worked hard for 102 years, until 1887.

Moving to Australia

When the engine was taken out of service in 1887, it was almost thrown away. But Archibald Liversidge, a scientist from the University of Sydney, heard about it. He was in London at the time. He asked if the engine could be given to the museum in Sydney. Whitbread & Co agreed, as long as it was used for teaching people.

So, the engine was taken apart and shipped to Sydney. It traveled on a sailing ship called the Patriarch. The huge flywheel had to be cut in half to fit on the ship. It took a few years to set up the engine because there wasn't enough money.

Eventually, the engine was put in its own building at the museum. In the 1920s or 1930s, an electric motor was added. This allowed visitors to see the engine move without needing steam. Later, in the 1980s, a group helped raise money to fully restore the engine.

The engine was moved to the new Powerhouse Museum in 1988. Today, you can sometimes see it running as part of the museum's "Steam Revolution" exhibit. Steam for the engine comes from the museum's main boiler.

How the Engine Works

The Whitbread Engine has a piston that is about 0.64 meters (25 inches) wide. This piston moves up and down 1.8 meters (6 feet) with each stroke. The engine's top speed is 20 spins per minute for its large flywheel. When it was new, it could produce about 26 kilowatts (35 horsepower) of power.

In 1795, the engine was changed to be "double-acting." This meant the piston could push and pull the beam. Later, a special device called a centrifugal governor was added. This governor helps control the engine's speed automatically. Also, the main beam and driving rod, which were originally made of wood, were replaced with strong iron parts.

This engine is important because it shows four big ideas that made Boulton and Watt's engines so powerful. These ideas helped start the Industrial Revolution.

- Separate Condenser: This part keeps the main cylinder hot. This makes the engine work much more efficiently.

- Parallel Motion: This clever design turns the piston's straight up-and-down movement into the beam's arcing motion. It keeps a strong connection, which allowed the engine to be double-acting.

- Centrifugal Governor: This device automatically adjusts the steam going into the engine. It keeps the engine running at a steady speed.

- Sun and Planet Gear: This special gear system changes the up-and-down motion of the beam into a spinning motion. This spinning power could then drive all sorts of factory machines.

See also

- Murray's Hypocycloidal Engine – another old working engine with a special gear

| Jewel Prestage |

| Ella Baker |

| Fannie Lou Hamer |