Whitchurch Silk Mill facts for kids

Quick facts for kids Whitchurch Silk Mill |

|

|---|---|

|

|

| Type | Fulling mill Silk mill |

| Location | Whitchurch |

| OS grid reference | SU4625247901 |

| Area | Hampshire |

| Built | 1800 |

| Owner | Hampshire Buildings Preservation Trust |

|

Listed Building – Grade II*

|

|

| Official name: Whitchurch Silk Mill | |

| Designated | 10 Jan 1953 |

| Reference no. | 1092645 |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

Whitchurch Silk Mill is a fascinating old watermill located in the town of Whitchurch, Hampshire, England. It sits right on the River Test. This special building is recognized as a Grade II* listed building, which means it's an important historical site that needs to be protected.

Contents

A Look Back at the Mill's History

The Whitchurch Silk Mill was built way back in 1800. A man named Henry Hayter constructed it on a piece of land known as Frog Island. It's thought that there might have been a mill on this very spot even earlier, perhaps one of the four mills mentioned in the ancient Domesday Book.

From Cloth to Silk

When it was first built, the mill was a fulling mill. This means it was used for a part of the process of making cloth, helping to clean and thicken it. However, things changed a few years later. In 1817, William Madick bought the mill. He decided to change its purpose to throw silk, which involves twisting silk fibers into thread.

Owners and Workers Through Time

In 1844, two merchants from Manchester, Alexander Bannerman and John Spencer, took over the mill. Then, in 1846, William Chappell, who was the mill's manager, bought it from them. At this time, the mill was a busy place, employing 108 people. This included 39 children who were under 13 years old, which was common for factories in those days.

By 1866, the Hide family owned the mill. They kept it in their family until James Hide passed away in 1955. During this period, the mill was famous for weaving silk for Burberry. Burberry, a well-known fashion company, used this silk as colorful linings for their raincoats.

Becoming a Public Treasure

After the Hide family, the mill was operated by Ede and Ravenscroft until 1985. They used the mill to produce special silk for legal and academic gowns. In 1985, the Hampshire Buildings Preservation Trust bought the mill. After doing some important repair work, they opened it to the public in 1990. This allowed everyone to visit and learn about its history.

In December 2012, the people in charge of the mill decided to start making silk there again. This means visitors can now see silk being woven using traditional methods.

How the Mill is Managed Today

The Hampshire Buildings Preservation Trust still owns the Whitchurch Silk Mill. However, they lease it to a special group called the Whitchurch Silk Mill Trust. This trust makes sure the mill is looked after and preserved for the future.

The Whitchurch Silk Mill Trust is a registered charity. This means it's a non-profit organization dedicated to a good cause. They explain their mission like this:

"Whitchurch Silk Mill Trust weaves silk on Victorian machinery in the Georgian watermill of Whitchurch Silk Mill, Hampshire. The mill is open to the public who come from across the UK and abroad. The charity educates visitors about silk, retains and develops the skills of silk weaving and restores its historic machinery."

Local groups, including the Town Council, and many people from the public have given their support to the Silk Mill. Their help has been very important in bringing silk weaving back to life at the mill.

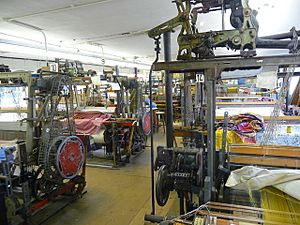

The Mill's Amazing Machinery

The mill used to get its power from a large water wheel. This wheel was about 5 feet 6 inches (1.68 meters) across. It turned a system of line shafting which then powered all the machines.

Today, the mill has 15 looms in total.

- 10 of these are Tappet looms, which are very old, dating from 1890 to 1932.

- There are also 3 Dobby looms from the 1950s.

- Finally, there are 2 Hattersley looms from the 1960s, which were brought to the mill in 1972.

While the water wheel was once key, these days each loom is powered by its own electric motor. The mill also has a warping mill and winding frames, which are also from the 1890s. These machines are all important for preparing the silk threads before they are woven into fabric.