Silk facts for kids

Silk is a natural protein fiber. People can weave some types of silk into textiles, which are kinds of cloth. The silk fiber is mostly made of a protein called fibroin. It is created by certain insect larvae, or young insects, to build their cocoons.

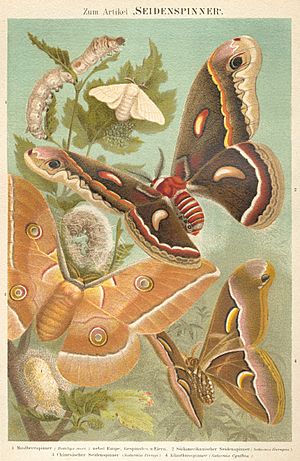

The most famous silk comes from the cocoons of larvae of the mulberry silkworm Bombyx mori. These silkworms are raised by humans in a process called sericulture. Silk cloth looks shiny because its fibers have a special triangular shape, like tiny prisms. This shape makes light bounce off the silk at different angles, creating many beautiful colors.

Many insects produce silk, but usually, only the silk from moth caterpillars is used to make cloth. Scientists have also studied other kinds of silk, which are different at a tiny, molecular level. Most silk is made by insect larvae that go through complete metamorphosis, meaning they change a lot as they grow. However, some insects, like webspinners and raspy crickets, make silk their whole lives. Other insects that produce silk include Hymenoptera (like bees, wasps, and ants), silverfish, mayflies, thrips, leafhoppers, beetles, lacewings, fleas, flies, and midges. Other arthropods, especially spiders, also make silk.

Contents

- What's in a Name? The Word "Silk"

- A Journey Through Time: The History of Silk

- Wild Silk: Nature's Own Threads

- Silk in China: A Secret Treasure

- Silk in India: A Rich Tradition

- Silk in Thailand: Hand-Woven Beauty

- Silk in Bangladesh: A Historic Trade

- Silk in Ancient Mediterranean Lands

- Silk in the Middle East

- Silk in Medieval and Modern Europe

- Silk in North America

- Silk in Malaysia and Vietnam

- How Silk is Made: The Production Process

- What Makes Silk Special: Its Properties

- Related Topics

- Images for kids

- See also

What's in a Name? The Word "Silk"

The word "silk" comes from an old English word, Old English: sioloc. This word came from the Greek word Ancient Greek: σηρικός, romanized: sērikós, which means "silken." Ultimately, the word came from Asia. For example, in Mandarin Chinese, "silk" is sī.

A Journey Through Time: The History of Silk

Wild Silk: Nature's Own Threads

For a long time, people in China, South Asia, and Europe knew about and used different kinds of wild silk. These silks came from caterpillars other than the mulberry silkworm. However, people made much less wild silk than cultivated silk.

There were a few reasons for this. First, wild silks had different colors and textures, so they weren't all the same. Second, when people found cocoons in the wild, the moth had usually already left. This meant the silk thread was broken into shorter pieces. Third, many wild cocoons have a mineral layer that makes it hard to unwind long silk strands. Because of this, the only way to get wild silk for weaving was through a lot of hard work, by carding it (like brushing wool).

Some natural silk structures were used without being unwound. For example, people in ancient Greece and Rome used spider webs as bandages. In the Aztec Empire, people glued caterpillar nests together to make fabric.

Commercial silk comes from silkworm pupae that are raised by humans. These silkworms are bred to make white silk threads without a mineral layer. The pupae are killed before the adult moths come out, either by boiling them or by piercing them with a needle. This allows the entire cocoon to be unwound as one long, continuous thread. This long thread helps create a much stronger silk cloth. Wild silks are also harder to dye than silk from cultivated silkworms.

Silk in China: A Secret Treasure

Silk was first made in ancient China. The oldest proof of silk comes from soil samples in tombs in Jiahu, Henan, dating back about 8,500 years. The oldest piece of silk fabric found is from around 3630 BC. It was used to wrap a child's body at a site near Xingyang, Henan.

Legend says that a Chinese empress, Leizu, discovered how to make silk. At first, only the Emperors of China could use silk or give it as gifts. But slowly, silk spread throughout Chinese culture and trade, reaching many parts of Asia. Because of its feel and shine, silk quickly became a popular luxury fabric. It was in high demand and became a very important item for international trade before the Industrial Revolution.

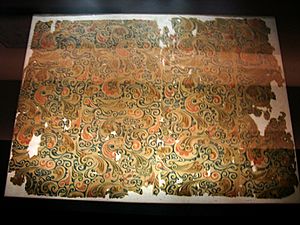

In 2007, archaeologists found beautifully woven and dyed silk fabrics in a tomb in Jiangxi province. These silks were from the Eastern Zhou dynasty, about 2,500 years ago. This discovery showed that ancient China had advanced silk-making skills much earlier than previously thought.

The first sign of silk being traded far away is a silk finding in the hair of an Egyptian mummy from around 1070 BC. Silk trade reached places like India, the Middle East, Europe, and North Africa. This trade was so big that the main trade routes between Europe and Asia became known as the Silk Road.

The Chinese emperors tried to keep the knowledge of sericulture a secret. They wanted to keep China's monopoly on silk. However, sericulture eventually reached Korea around 200 BC, the ancient Kingdom of Khotan by AD 50, and India by AD 140. In ancient times, Chinese silk was the most valuable and wanted luxury item traded across Asia and Europe. Many civilizations, like the ancient Persians, made money from this trade.

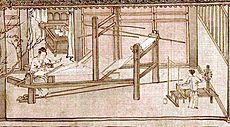

- How Chinese Silk Was Made

Silk in India: A Rich Tradition

India has a long history with silk. It is called Resham in eastern and northern India, and Pattu in southern India. Recent discoveries in Harappa and Chanhu-daro suggest that silk production, using wild silk from local silkworms, existed in South Asia during the Indus Valley civilization (around 2450 BC to 2000 BC). This was around the same time as early silk production in China.

India is the second largest producer of silk in the world, after China. About 97% of India's raw mulberry silk comes from six states: Andhra Pradesh, Karnataka, Jammu and Kashmir, Tamil Nadu, Bihar, and West Bengal. Ramanagara and Mysore in Karnataka are major silk production areas.

In Tamil Nadu, mulberry farming is common in the Coimbatore, Erode, Bhagalpuri, Tiruppur, Salem, and Dharmapuri districts. India's first automatic silk reeling factories were in Hyderabad and Gobichettipalayam.

India is also the biggest consumer of silk in the world. Wearing silk sarees for weddings and other special events is a tradition in Assam and southern India. Silk is seen as a symbol of royalty. Historically, only the upper classes used silk. Famous silk garments and sarees are made in places like Kanchipuram, Pochampally, Dharmavaram, Mysore, Arani (in the south), Banaras (in the north), and Bhagalpur and Murshidabad (in the east). In the northeastern state of Assam, three unique types of silk are produced: Muga, Eri, and Pat silk. Muga, also called golden silk, and Eri silk come from silkworms found only in Assam.

Silk in Thailand: Hand-Woven Beauty

Silk is made all year in Thailand by two kinds of silkworms: the farmed Bombycidae and wild Saturniidae. Most silk is produced after the rice harvest in the southern and northeastern parts of the country. Women traditionally weave silk on hand looms. They pass this skill down to their daughters. Weaving is seen as a sign that a girl is grown up and ready for marriage.

Thai silk fabrics often have complex patterns with many colors and styles. Most regions in Thailand have their own special silks. A single silk filament is too thin to use alone. So, women combine many threads to make a thicker, usable fiber. They do this by hand-reeling the threads onto a wooden spindle. This creates a smooth strand of raw silk. It takes about 40 hours to make half a kilogram of silk this way. Many local businesses now use machines for this, but some silk threads are still hand-reeled. Hand-reeled threads produce three grades of silk: two fine grades for light fabrics and a thick grade for heavier materials.

Before dyeing, the silk fabric is soaked in very cold water and bleached. This removes the natural yellow color of Thai silk yarn. Silk threads are dipped in large tubs of hydrogen peroxide. Once washed and dried, the silk is woven on a traditional hand-operated loom.

Silk in Bangladesh: A Historic Trade

The Rajshahi Division in northern Bangladesh is a major center for the country's silk industry. Three types of silk are made there: mulberry, endi, and tassar. Bengali silk was a very important item in international trade for hundreds of years. In medieval Europe, it was known as Ganges silk. Bengal was the top exporter of silk between the 16th and 19th centuries.

Silk in Ancient Mediterranean Lands

In the ancient Greek story Odyssey, there's a description of a shirt that "gleamed like the skin of a dried onion." This might have been a reference to shiny silk fabric. Aristotle wrote about Coa vestis, a wild silk fabric from the island of Kos. Sea silk, which comes from certain large seashells, was also valuable.

The Roman Empire knew about and traded silk. Chinese silk was the most expensive luxury item they imported. During the rule of Emperor Tiberius, laws were made to stop men from wearing silk clothes, but these laws didn't work. The Historia Augusta says that Emperor Elagabalus in the 3rd century was the first Roman to wear clothes made only of silk. Before him, people usually wore fabrics mixed with silk and cotton or silk and linen.

Even though silk was popular, the secret of how to make it only reached Europe around AD 550. This happened through the Byzantine Empire. A legend says that monks working for Emperor Justinian I secretly brought silkworm eggs to Constantinople hidden inside hollow canes from China. The best looms and weavers were kept inside the Great Palace in Constantinople. The silk cloth they made was used for royal robes or as gifts to important people from other countries. Any extra silk was sold at very high prices.

Silk in the Middle East

In the Torah, a scarlet cloth called "sheni tola'at" (meaning "crimson of the worm") is mentioned. It was used in special cleaning ceremonies. A famous scholar, Rabbi Saadia Gaon, translated this phrase as "crimson silk."

In Islamic teachings, Muslim men are not allowed to wear silk. Many religious experts believe this rule is to prevent men from wearing clothes that might seem too feminine or too fancy. There are discussions about how much silk a fabric can have (for example, if a small silk decoration on a cotton robe is allowed). However, most Muslim scholars agree that men should not wear silk. Modern clothes have brought up new questions, like whether men can wear silk neckties, which are seen as masculine.

Silk in Medieval and Modern Europe

Italy was the most important silk producer during the Middle Ages. The city of Catanzaro in Calabria was the first place in Italy to start making silk in the 11th century. Catanzaro's silk was sold all over Europe. It was traded at a big market in Reggio Calabria to Spanish, Venetian, Genovese, and Dutch merchants. Catanzaro became known as the lace capital of the world. It had a large silkworm farm that produced all the laces and linens used in the Vatican. The city was famous for its beautiful silks, velvets, damasks, and brocades.

Another important place was the Italian city-state of Lucca. It made a lot of money from silk production and trade starting in the 12th century. Other Italian cities involved in silk making were Genoa, Venice, and Florence.

The Silk Exchange in Valencia, built in the 15th century, shows how powerful and wealthy this Mediterranean trading city was. Silk was also produced and exported from the province of Granada, Spain, especially the Alpujarras region. This continued until the Moriscos, who ran the industry, were forced out of Granada in 1571.

Since the 15th century, silk production in France has been centered around the city of Lyon. Many mechanical tools for making silk in large amounts were first used there in the 17th century.

King James I tried to start silk production in England around 1619. He bought and planted 100,000 mulberry trees. However, these trees were not the right kind for silkworms, so the effort failed. In 1732, John Guardivaglio started a silk spinning business in Stockport. Later, other mills were built in Macclesfield and Congleton. These three towns were the center of the English silk spinning industry until it was replaced by spinning silk waste. British companies also set up silk factories in Cyprus in 1928. In the mid-20th century, raw silk was produced at Lullingstone Castle in Kent, England. Silkworms were raised there, and the silk was reeled under the direction of Zoe Lady Hart Dyke.

- Silk in Europe

-

The necktie came from the cravat, a neckband often made from silk.

Silk in North America

The Aztecs in North America used wild silk from native caterpillar nests to make containers and paper. Silkworms were brought to Oaxaca, Mexico, from Spain in the 1530s. The region made money from silk until the early 17th century, when the king of Spain stopped exports to protect Spain's own silk industry. Silk production for local use has continued there to this day, sometimes using wild silk.

King James I introduced silk farming to the British colonies in America around 1619. He hoped it would make people plant less tobacco. The Shakers in Kentucky also started raising silkworms.

The history of industrial silk in the United States is linked to several smaller cities in the Northeast. In the 1830s, Manchester, Connecticut, became an early center for silk. The Cheney Brothers were the first in the US to raise silkworms on a large scale. Today, the Cheney Brothers Historic District shows their old mills. Other smaller producers started raising silkworms, especially near Northampton, Massachusetts. One important group was the Northampton Association for Education and Industry, where Sojourner Truth was a member.

After a big flood in 1874, a manufacturer named William Skinner moved his mill to Holyoke. Over the next 50 years, he and his sons grew their business. By 1911, the Skinner Mill complex had the largest silk mill in the world under one roof. The brand Skinner Fabrics became the biggest maker of silk satins worldwide. Later in the 19th century, the silk industry also came to Paterson, New Jersey. Many European textile workers were hired there, earning it the nickname "Silk City" as another major US production center.

World War II stopped the silk trade from Asia, and silk prices went up a lot. The US industry started looking for other materials, which led to the use of synthetics like nylon. Synthetic silks have also been made from lyocell, a type of plant fiber. It can be hard to tell them apart from real silk.

Silk in Malaysia and Vietnam

In Terengganu, which is now part of Malaysia, a second type of silkworm was brought in as early as 1764 for the country's silk textile industry, especially for a fabric called songket. However, since the 1980s, Malaysia no longer raises silkworms, but it still grows mulberry trees. In Vietnamese legend, silk appeared thousands of years ago and is still woven today.

How Silk is Made: The Production Process

The process of making silk is called sericulture. It involves several steps, often done by different groups of people. First, silkworms are raised and fed mulberry leaves. Once the worms start to form their cocoons, these cocoons are put into boiling water. This helps to dissolve the natural glue that holds the cocoon together, allowing the long, individual silk fibers to be pulled out and wound onto a spinning reel.

To make 1 kilogram (about 2.2 pounds) of silk, 3,000 silkworms need to eat 104 kilograms (about 229 pounds) of mulberry leaves. It takes about 5,000 silkworms to make enough silk for one pure silk kimono. The main countries that produce silk are China (54%) and India (14%).

| Top Ten Silk Cocoon Producers — 2005 | ||||

|---|---|---|---|---|

| Country | Production (1000 kg) | |||

| 290,003 | ||||

| 77,000 | ||||

| 17,000 | ||||

| 11,000 | ||||

| 6,088 | ||||

| 5,000 | ||||

| 3,000 | ||||

| 1,500 | ||||

| 1,000 | ||||

| 600 | ||||

Making silk can have a big impact on the environment compared to other natural fibers. For example, making Indian silk uses a lot of carbon and water. This is mainly because it's an animal product, and more resources like fertilizer and water are needed for each unit of fiber produced.

What Makes Silk Special: Its Properties

Physical Properties of Silk

Silk fibers from the Bombyx mori silkworm are shaped like tiny triangles with rounded corners. They are about 5–10 μm (micrometers) wide. The flat surfaces of these tiny fibers reflect light from many angles, which gives silk its natural shine. Silk from other silkworms can have different shapes and sizes. For example, Anaphe silk is crescent-shaped, and tussah silk is like a long wedge. Silkworm fibers come out of two glands as a pair of main threads. These threads are stuck together by a protein called sericin, which acts like glue.

Silk feels smooth and soft, but it's not slippery like many synthetic fibers.

Silk is one of the strongest natural fibers. However, it can lose up to 20% of its strength when it gets wet. It absorbs moisture well, about 11% of its weight. Silk's elasticity (how well it stretches and returns to its original shape) is not very good. If it's stretched even a little, it tends to stay stretched. Too much sunlight can weaken silk. Insects can also attack silk, especially if it's dirty.

An example of how durable silk is comes from 1840. Silk clothes were found from a shipwreck from 1782. The silk was still perfect, even though the lining had completely rotted away. This shows how strong silk can be compared to other fabrics.

Silk does not conduct electricity well, so it can create static cling. Silk also releases infrared light well, which makes it feel cool to the touch.

Unwashed silk chiffon fabric might shrink up to 8% because the fibers relax. So, silk should be washed before making clothes, or dry cleaned. Dry cleaning can still shrink chiffon up to 4%. Sometimes, this shrinkage can be undone by gently steaming the fabric. Silk usually doesn't shrink slowly over time or due to changes at the molecular level.

Natural and synthetic silk can show piezoelectric properties in their proteins. This means they can create a small electric charge when squeezed or stretched.

Silkworm silk was used as the standard for the denier, which is a way to measure the thickness of fibers. Silkworm silk has a thickness of about 1 denier.

| Comparison of Silk Fibers | Thickness (dtex) | Diameter (μm) |

|---|---|---|

| Moth: Bombyx mori | 1.17 | 12.9 |

| Spider: Argiope aurentia | 0.14 | 3.57 |

Related Topics

Images for kids

-

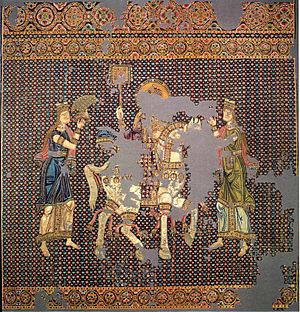

A Chinese Embassy group carrying silk and silkworm cocoons in the 7th century CE, Afrasiyab, Sogdia.

See also

In Spanish: Seda para niños

In Spanish: Seda para niños

| Claudette Colvin |

| Myrlie Evers-Williams |

| Alberta Odell Jones |