Bergius process facts for kids

The Bergius process is a way to make liquid fuels, like gasoline, from coal. It uses a special method called hydrogenation, which means adding hydrogen to coal under very high heat and pressure. This process was invented by Friedrich Bergius in 1913. He later won the Nobel Prize in Chemistry in 1931 for his work on high-pressure chemistry.

Contents

How the Bergius Process Works

To start, coal is ground into a very fine powder. Then, it is dried using hot gas. This dry coal powder is mixed with a thick oil that comes from the process itself.

A special substance called a catalyst is usually added to this mixture. A catalyst helps chemical reactions happen faster without being used up itself. Many different catalysts can be used, like tungsten or molybdenum disulfide. Sometimes, natural iron sulfide found in the coal is enough to act as a catalyst. This was how the original Bergius process worked.

The coal mixture is then pumped into a large container called a reactor. Inside the reactor, the temperature is very hot, between 400 and 500 degrees Celsius. The pressure is also extremely high, up to 70 times the pressure of the deepest ocean. Hydrogen gas is also added to the reactor.

This reaction creates several products: heavy oils, middle oils, gasoline, and gases. The main idea is that coal, which is mostly carbon, reacts with hydrogen to form liquid fuels.

The liquid product from the reactor needs to be made stable. This is done by passing it over another catalyst. The final liquid fuel is rich in certain types of chemicals called cycloalkanes and aromatics. It has very few alkanes and almost no alkenes.

These different liquid parts can be further processed. For example, they can be put through cracking or reforming. These steps turn the liquids into the desired type of synthetic fuel. If processed further, most of the cycloalkanes become aromatics. The hydrogen that is recovered can be used again in the process. The final gasoline can have a very high Research Octane Number, which means it burns very well in engines.

About 97% of the carbon from the coal can be turned into synthetic fuel. However, if hydrogen is made from coal, some carbon is lost as carbon dioxide. This lowers the overall efficiency of the process.

After the process, there is a leftover sticky tar mixed with ash from the coal and the catalyst. To avoid wasting too much carbon, the coal used should have very little ash. The hydrogen needed for the process can also be made from coal or the leftover residue. About 80 kilograms of hydrogen are needed for every ton of dry coal. The heavy oil and middle oil created can be reused by mixing them with new coal. This helps to get more gasoline from the process.

A more modern version of this process was tested in Wilsonville, Alabama. This plant operated from 1981 to 1985. It prepared a coal extract using finely crushed coal and a special solvent. As the coal broke down, it absorbed hydrogen from the solvent. This extract then went to another reactor, where more hydrogen was added. This step created smaller liquid hydrocarbons and removed sulfur, oxygen, and nitrogen from the coal. Part of the liquid product was recycled as the solvent. The rest was separated into different fuels and an ash-filled residue. This residue could be used to make the hydrogen needed for the process.

History of the Bergius Process

Friedrich Bergius developed the Bergius process during his studies. He received a patent for his method of using high pressure and temperature on carbon-containing materials in 1913. This process made liquid fuels from lignite (brown coal) by adding hydrogen. He developed this method before the well-known Fischer–Tropsch process.

In 1914, Karl Goldschmidt invited Bergius to build a large industrial plant. This plant was at his factory, Th. Goldschmidt AG (now Evonik Industries). Production finally started in 1919, after World War I ended. At that time, the need for fuel was decreasing.

The process faced many challenges, including technical problems and high inflation. Also, another chemist, Franz Joseph Emil Fischer, often criticized it. However, after Bergius showed him how it worked, Fischer started to support it. Because of these difficulties, Bergius sold his patent to BASF. There, Carl Bosch continued to work on improving the process.

Before World War II, several plants were built using the Bergius process. These plants could produce 4 million tons of synthetic fuel each year. During World War II, these factories were very important. They supplied Germany with much-needed fuel and lubricants.

Past Uses of the Bergius Process

Today, coal hydrogenation using the Bergius process is not used commercially.

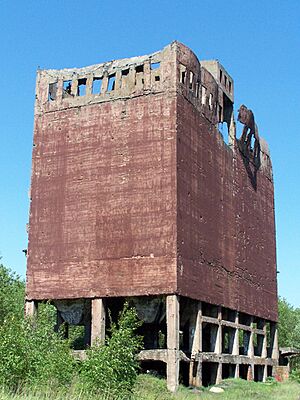

The Bergius process was used a lot by Brabag, a company in Nazi Germany. Plants that used this process were targets for bombing during the Oil Campaign of World War II. Currently, no plants are using the Bergius Process or its newer versions for commercial production. The largest demonstration plant, which could produce 200 tons per day, was in Bottrop, Germany. It was run by Ruhrkohle and stopped operating in 1993. There were reports that a Chinese company was building a much larger plant, but it's not confirmed if it became operational.

Towards the end of World War II, the United States started investing heavily in research to turn coal into gasoline. This project greatly benefited from German technology captured during the war. One plant using the Bergius process was built in Louisiana, Missouri. It started operating around 1946. By 1948, this plant was making gasoline in large amounts. The gasoline produced was a bit more expensive than regular gasoline but was of higher quality. The plant was shut down in 1953 by the Eisenhower administration. Some believe this happened because of strong pressure from the oil industry.

See also

- Synthetic Liquid Fuels Program

- Fischer–Tropsch process

- Karrick process

- Coal-water slurry fuel

Images for kids

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |