Fischer–Tropsch process facts for kids

The Fischer–Tropsch process is a special set of chemical reactions that turn a mix of carbon monoxide (CO) and hydrogen (H2) gases into liquid hydrocarbons. This gas mixture is often called syngas. These reactions happen with the help of special materials called catalysts, usually metals. They work at temperatures from about 150 to 300 degrees Celsius (300-570 degrees Fahrenheit) and at high pressures.

The Fischer–Tropsch (FT) process is very important for making liquid fuels from other sources. For example, it's used in coal liquefaction (turning coal into liquid fuel) and gas to liquids (GTL) technology.

Usually, the carbon monoxide and hydrogen needed for the FT process come from coal, natural gas, or biomass (like plants or waste). This first step is called gasification. After that, the FT process changes these gases into synthetic oils and synthetic fuel. This method has been looked at many times as a way to get diesel fuel with less sulfur, and to help with the supply or cost of fuels made from regular petroleum. Some even talk about using the Fischer–Tropsch process to make carbon-neutral fuels from CO2 and hydrogen.

The process was first created by two scientists, Franz Fischer and Hans Tropsch, in Germany in 1925. They worked at the Kaiser Wilhelm Institute for Coal Research.

Contents

How the Fischer–Tropsch Process Works

The Fischer–Tropsch process involves a series of chemical reactions that create many different hydrocarbons. Ideally, these hydrocarbons have the formula (CnH2n+2). The most useful reactions make alkanes, which are a type of hydrocarbon, like this:

- (2n + 1) H2 + n CO → CnH2n+2 + n H2O

Here, 'n' is usually a number between 10 and 20. Making methane (where 'n' = 1) is usually not wanted. Most of the alkanes made are straight-chain molecules, which are good for diesel fuel. Besides alkanes, some other reactions also happen, making small amounts of alkenes, as well as alcohols and other hydrocarbons that contain oxygen.

These reactions release a lot of heat, which means they are highly exothermic.

Steps in the Reaction

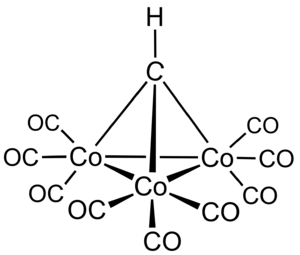

Turning a mix of hydrogen (H2) and carbon monoxide (CO) into liquid products is a multi-step process. It involves several intermediate compounds, which are temporary molecules formed during the reaction. Imagine the hydrocarbon chain growing by adding hydrogen atoms to carbon and oxygen. Then, the bond between carbon and oxygen breaks, and a new bond between two carbon atoms forms.

For each –CH2– group made from CO + 2 H2 → (CH2) + H2O, several steps are needed:

- CO gas sticks to the catalyst surface.

- The bond between carbon and oxygen breaks.

- Hydrogen gas (H2) also sticks to the catalyst and breaks apart.

- Two hydrogen atoms combine with the oxygen to make water (H2O).

- The water leaves the catalyst surface.

- Two hydrogen atoms combine with the carbon to make CH2.

The conversion of CO to alkanes involves adding hydrogen to CO, breaking C–O bonds with hydrogen, and forming new C–C bonds. Scientists believe these reactions start with carbon monoxide molecules attaching to the metal catalyst.

Starting Materials: Syngas Production

Fischer–Tropsch plants that use coal or other solid materials as their starting point must first turn these solids into gases. These gases include CO, H2, and other hydrocarbons. This process is called gasification. The gas mixture, called "syngas," is made of hydrogen and carbon monoxide. The ratio of H2 to CO can be adjusted using another reaction called the water-gas shift reaction.

Gas to Liquids (GTL)

In gas to liquids (GTL) technology, the carbon monoxide for the FT process comes from hydrocarbons. These are often small molecules of natural gas that might otherwise be wasted. GTL is a good option when natural gas is cheaper than oil.

Before the gases enter the FT reactor, they must be cleaned to remove sulfur. If sulfur is present, it can "poison" or deactivate the catalysts needed for the FT reactions.

Several reactions are used to get the right H2:CO ratio. The most important is the water-gas shift reaction, which makes more hydrogen from carbon monoxide:

- <chem>H2O + CO -> H2 + CO2</chem>

For FT plants that use methane (natural gas) as the feedstock, another important reaction is dry reforming. This turns methane into CO and H2:

- <chem>CH4 + CO2 -> 2CO + 2H2</chem>

Process Conditions

The Fischer–Tropsch process usually runs at temperatures between 150 and 300 degrees Celsius (300-570 degrees Fahrenheit). Higher temperatures make the reactions happen faster and convert more gas, but they also tend to make more unwanted methane. So, the temperature is usually kept in the lower to middle part of this range.

Increasing the pressure leads to higher conversion rates and also helps form longer alkane chains, which are both good things. Typical pressures range from one to several tens of atmospheres. Even higher pressures would be helpful, but the extra cost of high-pressure equipment might not be worth it. Also, very high pressures can cause the catalyst to stop working well due to coke (carbon) buildup.

Different syngas compositions can be used. For catalysts made with cobalt, the best H2:CO ratio is around 1.8–2.1. Catalysts made with iron can handle lower ratios because the iron catalyst itself helps with the water-gas shift reaction. This is useful for syngas from coal or biomass, which often have low H2:CO ratios (less than 1).

Fischer–Tropsch Reactor Design

A key challenge for FT reactors is removing the large amount of heat produced by the reactions. Here are some types of reactors used:

Multi-tubular Fixed-bed Reactor

This reactor has many small tubes filled with the catalyst. Cooling water surrounds these tubes to take away the heat from the reaction. This type of reactor works well at lower temperatures, up to about 257 °C (530 K). If the temperature gets too high, carbon can build up and block the reactor. Since many liquid products are formed, this can also be called a trickle flow reactor.

Slurry Reactors

In these reactors, heat is removed by internal cooling coils. The syngas bubbles through a liquid mixture of waxy products and tiny catalyst particles. This also helps stir the contents. Using small catalyst particles helps with heat transfer and mass transfer. A lower temperature in the reactor makes the product more thick and waxy. A higher temperature (above 297 °C, 570 K) can lead to less desirable products. Separating the product from the catalyst can also be a challenge.

Fluid-bed and Circulating Catalyst Reactors

These reactors are used for high-temperature FT synthesis (around 340 °C) to make smaller, unsaturated hydrocarbons using iron catalysts. This technology was first used in the 1940s and 50s. Sasol, a company in South Africa, has improved and uses these reactors. For example, at their Secunda plant, Sasol operates many large reactors of this type.

Product Distribution

The mix of hydrocarbons produced in the Fischer–Tropsch process generally follows a pattern called the Anderson–Schulz–Flory distribution. This can be shown by a formula:

- Wnn = (1 − α)2αn−1

Here, Wn is the amount of hydrocarbons with n carbon atoms, and α (alpha) is the "chain growth probability." This 'alpha' tells us how likely it is that a molecule will keep reacting to form a longer chain. The catalyst and the specific conditions of the process mostly determine 'alpha'.

This formula shows that methane will always be the largest single product if 'alpha' is less than 0.5. However, by making 'alpha' closer to one, the total amount of methane can be greatly reduced compared to all the longer-chained products. Increasing 'alpha' means more long-chained hydrocarbons are formed. Very long-chained hydrocarbons are waxes, which are solid at room temperature. To make liquid fuels, these waxes might need to be "cracked" (broken down) into smaller molecules.

Catalysts Used

Four metals can act as catalysts for the Fischer–Tropsch process: iron, cobalt, nickel, and ruthenium. Since the FT process usually turns cheap starting materials into complex mixtures that need more refining, the catalysts are made from inexpensive metals, especially iron and cobalt. Nickel makes too much methane, so it's not often used.

These catalysts are usually made by taking metal salts (like iron nitrate) and letting them settle out of a solution. These metal salts can then be placed onto a catalyst support (a material that holds the catalyst). These treated materials become active catalysts when heated with CO, H2, or the syngas.

Because the FT process has many steps, it's hard to study exactly how the active catalyst works. For iron catalysts, different forms of the metal, oxides, and carbides can exist at the same time and play different roles in the reaction. Controlling these different forms can affect the types of products made.

Besides iron and cobalt, ruthenium and nickel are also active. Even though it's expensive, ruthenium is the most active FT catalyst. It works at the lowest temperatures and makes heavier hydrocarbons. But its high price means it's not used much in industry.

Cobalt catalysts work better for FT synthesis when the starting material is natural gas. Natural gas has a lot of hydrogen, so the water-gas shift reaction isn't as needed for cobalt catalysts. Cobalt-based catalysts are more sensitive than iron ones.

For example, high-temperature Fischer–Tropsch (HTFT), which runs at 330–350 °C, uses an iron-based catalyst. This process was widely used by Sasol in their coal-to-liquid (CTL) plants. Low-temperature Fischer–Tropsch (LTFT) uses an iron- or cobalt-based catalyst. This process is famous for being used in the first large-scale GTL plant built by Shell in Malaysia.

Promoters and Supports

Besides the main active metal (usually iron or cobalt), FT catalysts also have two other parts: promoters and the catalyst support. Promoters are additives that make the catalyst work better. For FT catalysts, common promoters include potassium and copper, usually added as salts. The choice of promoter depends on the main metal. For example, iron catalysts need alkali promoters (like potassium) to work well and stay stable. Adding copper can help with reduction, and adding silica or alumina can help with the catalyst's structure. Some manganese can also be added to control which products are made (e.g., more alkenes). While alkali metals help iron catalysts, they can harm cobalt catalysts.

Catalysts are often placed on materials with a large surface area, called supports, such as silica, alumina, or zeolites.

History of Fischer–Tropsch

The Fischer–Tropsch (FT) process became very important in Nazi Germany as a way to produce liquid fuels. Germany had a lot of coal but not much oil. The original process was developed by Franz Fischer and Hans Tropsch in 1926. It was first used commercially in Germany in 1936. During World War II, Germany used the process to make "ersatz" (replacement) fuels. FT production made up about 9% of Germany's wartime fuel production and 25% of its car fuel. Many improvements have been made to the process since Fischer and Tropsch's time.

After the war, the United States Bureau of Mines even brought German scientists to a Fischer–Tropsch plant in Missouri in 1946 to learn more about the process.

In the 1930s and 1940s, a scientist named Arthur Imhausen developed a way to make edible fats from these synthetic oils through a process called oxidation. The products were separated, and the edible fats were made from a specific part of the oil. This ""coal butter" margarine" was found to be nutritious and tasty. It was even added to diets, providing a good amount of calories. However, making 1 kg of synthetic butter required at least 60 kg of coal.

Commercial Use Today

Ras Laffan, Qatar

The Pearl GTL plant in Ras Laffan, Qatar, is the second largest FT plant in the world. It uses cobalt catalysts at 230 °C to turn natural gas into liquid petroleum. It produces about 140,000 barrels of oil per day, plus other natural gas liquids.

Another plant in Ras Laffan, called Oryx GTL, started in 2007 and can produce 34,000 barrels of oil per day. This plant uses a Sasol process with a cobalt catalyst. Oryx GTL is a joint project between QatarEnergy and Sasol.

Sasol

The biggest use of Fischer–Tropsch technology in the world is by Sasol in South Africa. South Africa has large coal reserves but little oil. Sasol's plant in Secunda can produce 165,000 barrels per day. The first commercial plant opened in 1952. Sasol uses coal and natural gas to make various synthetic petroleum products, including most of South Africa's diesel fuel.

PetroSA

PetroSA, another South African company, runs a refinery with a 36,000 barrels per day plant. This plant completed testing in 2011 and is now preparing for full commercial use. This technology can turn natural gas, biomass, or coal into synthetic fuels.

Shell Middle Distillate Synthesis

One of the largest uses of Fischer–Tropsch technology is in Bintulu, Malaysia. This Shell facility turns natural gas into low-sulfur Diesel fuels and food-grade wax. It produces about 12,000 barrels of oil per day.

Velocys

Velocys is building a plant in Oklahoma City, USA, that uses its special microchannel Fischer–Tropsch technology. This project will use a mix of landfill gas and natural gas to make fuels.

UPM (Finland)

In 2006, Finnish paper company UPM announced plans to make biodiesel using the Fischer–Tropsch process. They plan to use waste biomass from their paper and pulp factories as the starting material.

INFRA GTL Technology

In 2010, INFRA built a small pilot plant to turn natural gas into synthetic oil. This plant showed the full process, from taking in natural gas to making synthetic oil. In 2015, INFRA built its own catalyst factory in Russia, producing special Fischer–Tropsch catalysts. In 2016, INFRA designed and built a portable GTL plant in Texas, USA, to process natural gas into synthetic crude oil.

New Developments

Audi

Car company Audi, working with Sunfire, makes E-diesel on a small scale. The second step of their process uses the FT reaction.

U.S. Air Force Fuel Certification

Syntroleum, a US company, has made over 400,000 US gallons of diesel and jet fuel using the Fischer–Tropsch process from natural gas and coal. They are working to sell their FT technology for coal-to-liquid plants in the US, China, and Germany, and gas-to-liquid plants worldwide.

The US Air Force, which uses a lot of fuel, started looking into alternative fuels in 1999. On December 15, 2006, a B-52 airplane flew for the first time using a 50–50 mix of regular jet fuel and Syntroleum's FT fuel. The flight was a success. This program aims to approve the fuel blend for use in B-52s and other aircraft. This is part of the Department of Defense's plan to get about half of its aviation fuel from alternative sources by 2016.

Carbon Dioxide Reuse

Normally, carbon dioxide (CO2) is not a main starting material for FT reactions. However, hydrogen and carbon dioxide can react over a cobalt catalyst to make methane. With iron catalysts, they can also make unsaturated short-chain hydrocarbons. Adding ceria to the catalyst can further increase the amount of product. These short-chain hydrocarbons can then be turned into liquid fuels using other catalysts like zeolites.

Process Efficiency

Using standard FT technology, the process can convert carbon with an efficiency of 25 to 50 percent. For plants that turn coal into liquid fuel (CTL), the energy efficiency is about 50%, with an ideal of 60%. For plants that turn gas into liquid fuel (GTL), the efficiency is about 60%, with an ideal of 80%.

Fischer–Tropsch in Nature

Scientists have even suggested that a process similar to Fischer–Tropsch might have created some of the basic building blocks of DNA and RNA inside asteroids. Also, the idea that abiogenic petroleum (oil not made from ancient living things) forms naturally would require some FT-like processes to happen in nature.

See also

In Spanish: Proceso Fischer-Tropsch para niños

In Spanish: Proceso Fischer-Tropsch para niños

- Bergius process

- Coal gasification

- Fischer assay

- Hydrogenation, a general term for this type of process

- Hubbert peak theory

- Industrial gas

- Karrick process

- Sabatier reaction

- Steam methane reforming

- Synthetic Liquid Fuels Program

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |