Fish processing facts for kids

Fish processing is all about what happens to fish and fish products from the moment they are caught until they reach you, the customer. This includes fish caught in the ocean or raised on fish farms.

Contents

Why Process Fish?

Fish is a food that can spoil very quickly. To make sure it stays fresh, safe, and tasty for a long time, it needs special handling and preservation. The main goal of fish processing is to stop fish from going bad.

One simple way to keep fish fresh is to keep them alive until you're ready to cook them. For thousands of years, people in China did this with carp.

Other ways to keep fish fresh include:

- Controlling temperature: Using ice, fridges, or freezers.

- Controlling water: Drying, salting, smoking, or freeze-drying fish.

- Killing tiny germs: Using heat (like microwaves) or special light.

- Adding chemicals: Using acids to stop germs from growing.

- Removing oxygen: Like with vacuum packing.

Often, people use more than one of these methods together. When chilled or frozen fish are moved from one place to another, they must stay cold. This is called keeping the "cold chain." It means using special containers or trucks that stay cold.

Fish processing also deals with managing waste and making fish products more valuable. There's a growing demand for fish products that are ready to eat or need very little cooking.

Handling Fish After Catching

When fish are caught for sale, they need to be handled carefully. This makes sure they stay fresh and undamaged until they reach the next step in the journey to your plate. For example, fish caught by a fishing vessel must be stored safely until the boat returns to shore.

Typical steps for handling fish include:

- Moving the fish from the fishing gear (like nets) onto the boat.

- Holding the fish before further steps.

- Sorting fish by size or type.

- Bleeding, gutting, and washing the fish.

- Chilling the fish.

- Storing the chilled fish.

- Unloading the fish when the boat gets back to port.

The order of these steps can change depending on the type of fish, the fishing gear, the size of the boat, how long it's at sea, and what the market needs. Modern fishing companies use equipment and methods designed to handle fish gently and make work safer for people.

Keeping Fish Alive

Another clear way to keep fish fresh is to keep them alive until they are sold or ready to be eaten. This is common around the world. Usually, fish are put into containers with clean water. Any dead, damaged, or sick fish are removed. The water temperature is then lowered, and the fish are not fed. This slows down their bodies and keeps the water cleaner.

Fish can be kept alive in floating cages, special wells, and fish ponds. In aquaculture (fish farming), holding tanks are used where the water is constantly cleaned, and its temperature and oxygen levels are controlled.

Preserving Fish

Preservation techniques are needed to stop fish from spoiling and make them last longer. These methods stop bad bacteria and other changes that make fish lose quality. Spoilage bacteria are the specific germs that create the bad smells and tastes of spoiled fish.

For bacteria to grow, they need the right temperature, enough water, oxygen, and surroundings that are not too acidic. Preservation techniques work by stopping one or more of these needs.

Controlling Temperature

If the temperature is lowered, the activity of tiny germs and natural changes in the fish can slow down or stop. This is done by refrigeration (cooling to about 0°C) or freezing (cooling below -18°C).

On fishing boats, fish are cooled by blowing cold air or by packing them in ice. Small fish, often caught in large numbers, are usually chilled with very cold water. Once fish are chilled or frozen, they need to stay cold. There are important things to consider when designing and managing cold storage, like how big and energy-efficient they are.

A very good way to keep fish fresh is to chill them with ice. Ice is spread evenly around the fish. It's a safe way to cool fish, keeps them moist, and makes them easy to store and transport. Ice is now easy and cheap to make because of modern fridges. Ice comes in different shapes, like crushed ice, flakes, plates, tubes, and blocks, all used to cool fish.

A special type of ice is slurry ice. This is made of tiny ice crystals mixed in water with a little salt. It cools fish very well. A newer method is pumpable ice technology. This ice flows like water and cools fish faster than regular ice. It also prevents "freeze burns" on the fish.

-

Fish cooling by pumpable ice.

Controlling Water

The "water activity" in fish measures how much water is available for germs and natural changes that cause spoilage. It's a number between 0 and 1. To stop spoilage, we need to reduce this available water.

Traditionally, methods like drying, salting, and smoking have been used for thousands of years. These can be very simple, like drying fish in the sun. More recently, freeze-drying and special chemicals that bind water have been added. Often, a mix of these methods is used.

-

Fish barn with fish drying in the sun, painted by Vincent van Gogh in 1882.

-

Salt fish dip in Jakarta.

Physical Control of Germs

Heat or special light can be used to kill the bacteria that cause fish to spoil. Heat is applied by cooking, blanching, or microwave heating. This process can pasteurize or sterilize fish products. Cooking or pasteurizing doesn't kill all germs, so the fish might still need to be refrigerated. Sterilized products can stay good at room temperature, but they need to be sealed in metal cans or special pouches before heating.

Chemical Control of Germs

Germs can also be stopped by adding special substances or by making the fish more acidic. Most bacteria stop growing when the fish is very acidic (pH less than 4.5). Acidity can be increased by fermenting the fish, marinating it, or by directly adding acids (like vinegar) to fish products. Some good bacteria produce natural germ-killers. Other preservatives include nitrites and sulphites.

Controlling Oxygen

Spoilage bacteria and fat spoilage usually need oxygen. So, reducing the oxygen around fish can make them last longer. This is done by controlling or changing the air around the fish, or by vacuum packaging. Controlled atmospheres have specific amounts of oxygen, carbon dioxide, and nitrogen. This method is often combined with refrigeration for better preservation.

Combining Techniques

Often, two or more of these techniques are used together. This can make preservation better and reduce unwanted side effects, like changing the nutrients with too much heat. Common combinations include salting/drying, salting/marinating, salting/smoking, and pasteurization/refrigeration.

Automated Processes

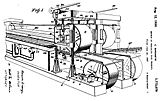

To make fish processing faster and more efficient, machines are now used. These include computer vision systems, electronic scales, and automatic machines that can remove skin and fillet fish.

-

A processing line for fish fingers.

Images for kids

-

Imitation crab and imitation shrimp made from surimi.

-

A medieval painting showing fish processing, by Pieter Bruegel the Elder (1556).

-

Filleting hake.

-

Filleting sole.

-

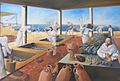

Egyptians bringing in fish and splitting them for salting.

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |