Kaiser Aluminum facts for kids

|

|

|

Formerly

|

Kaiser Aluminum and Chemical Company |

|---|---|

| Public | |

| Traded as | NASDAQ: KALU S&P 600 Component |

| Industry | Aluminum |

| Founded | 1946 in Washington state, U.S. |

| Headquarters | Franklin, Tennessee, U.S. |

|

Key people

|

Keith A. Harvey (president and CEO) |

| Products | Rolled aluminum, plate, sheet, can sheet, and extruded products. |

| Revenue | |

| Total assets | $1.865 billion (2020) |

|

Number of employees

|

3,700 (2021) |

| Subsidiaries | Anglesey Aluminium, Imperial Machine & Tool, Kaiser Warrick, LLC |

Kaiser Aluminum Corporation is an American company that makes aluminum products. It started as a part of a bigger company called Permanente Metals Corporation, which later changed its name to Kaiser Aluminum and Chemicals Corporation. Kaiser Aluminum then became its own separate company.

Contents

History of Kaiser Aluminum

Kaiser Aluminum was founded in 1946 by Henry J. Kaiser. The company began by renting, and later buying, three aluminum factories from the government in Washington state. These included plants in Mead, Tacoma, and Trentwood, plus an alumina refinery in Baton Rouge, Louisiana. The government wanted to help new companies like Kaiser compete with bigger aluminum producers like Alcoa and Reynolds.

In the early 1950s, Kaiser Aluminum grew a lot. It became a company that handled aluminum from start to finish. This meant they had their own mines in Jamaica, a refinery in Baton Rouge, and factories that melted and shaped aluminum in different parts of the country. They even used more factories that were left over from World War II and built new, large ones. This growth was also helped by the military needing a lot of aluminum for new production and for building up supplies during the Korean War.

Kaiser Aluminum also used to own a company that developed land, including areas in California, Oregon, Washington, and Arizona. They sold most of these land holdings in 1986.

In 1988, a company called Maxxam, Inc. bought Kaiser Aluminum's parent company. Later, in 2002, Kaiser Aluminum had to file for bankruptcy. This happened because of disagreements with workers, problems with electricity supply on the West Coast, and costs related to asbestos. The company worked hard and came out of bankruptcy four years later, in 2006.

Kaiser Aluminum used to own part of a company called Anglesey Aluminium in the UK. That factory closed down completely in 2013.

In April 2021, Kaiser Aluminum bought a factory from Alcoa called Alcoa Warrick, LLC, and renamed it Kaiser Warrick, LLC. This factory makes flat aluminum sheets used for food and drink cans. Kaiser Aluminum also announced plans to build a new production line at Kaiser Aluminum Warrick, which is expected to be ready by 2024.

About Kaiser Aluminum

Kaiser Aluminum's main office is in Franklin, Tennessee. In 2020, the company made about $1.173 billion in sales.

Kaiser Aluminum currently owns 13 factories that can produce over 400 million pounds of aluminum each year. Their North American factories make about 500 million pounds of special aluminum products every year. These products include sheets, plates, and other shapes used for many different things. With the addition of the Kaiser Warrick factory, Kaiser Aluminum now has about 3,700 employees.

Kaiser Aluminum Facilities

Historical Locations

Kaiser Aluminum leased the smelter at Mead in February 1946. A smelter is a place where metal is melted to separate it from other materials. This plant operated until 2004. 47°45′58″N 117°21′18″W / 47.76611°N 117.35500°W

The rolling mill at Trentwood was also leased in February 1946. A rolling mill shapes metal by passing it through rollers. This plant is still in operation today. 47°41′59″N 117°12′39″W / 47.69972°N 117.21083°W

The alumina refinery at Baton Rouge started operating for Kaiser in December 1946. An alumina refinery processes bauxite ore to make alumina, which is then used to produce aluminum. 30°27′36″N 91°11′06″W / 30.45996°N 91.18505°W

Kaiser bought the smelter at Tacoma in December 1946. This plant had been used during the war. 47°14′29″N 122°27′34″W / 47.24139°N 122.45944°W

From 1947 to 1950, Kaiser had a soda ash plant at Owens Lake. Soda ash is a chemical used in making aluminum. This plant helped solve a shortage of soda ash at the time. 36°26′00″N 117°57′03″W / 36.4332°N 117.9509°W

In 1948, Kaiser Aluminum bought the rod and wire mill at Newark. This factory made aluminum rods and wires, which could then be used to make even thinner wires or electrical cables. 40°00′55″N 82°27′57″W / 40.01541°N 82.46577°W

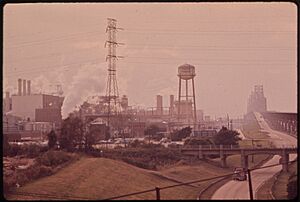

Construction of a new smelter at Chalmette began in 1950 and started production in 1951. This large plant helped double Kaiser's aluminum production. 29°56′15″N 89°58′52″W / 29.9376°N 89.98117°W

In March 1951, Kaiser leased the extrusion plant at Halethorpe. An extrusion plant pushes metal through a shaped opening to create long objects with a specific cross-section. 39°14′23″N 76°40′49″W / 39.23972°N 76.68028°W

In February 1953, Kaiser started shipping bauxite from its mining claim on Jamaica through Port Kaiser. Bauxite is the main ore used to make aluminum. This mine was a very important source for Kaiser's aluminum production. 17°51′45″N 77°36′18″W / 17.86255°N 77.60492°W

In October 1954, Kaiser leased the forging plant at Erie. A forging plant shapes metal by hammering or pressing it. 42°7′46″N 80°5′6″W / 42.12944°N 80.08500°W

In August 1954, Kaiser announced plans for a new factory at Ravenswood. This became an integrated mill at Ravenswood in 1955. It could perform all the steps of rolling and finishing aluminum sheets and foil. 38°55′58″N 81°49′34″W / 38.93264°N 81.82616°W

Other Historical Facilities

Kaiser also had a flourspar mine at Gabbs which closed in 1957 because its resources ran out. A flourspar mill at Fallon was also put on standby in 1957.

A magnesium plant at Manteca, California was operated by Kaiser Aluminum starting in January 1951 for a period.

Aluminum Production Numbers

Kaiser Aluminum also made agreements to buy primary aluminum from other companies, like Alcan in Canada, to help meet demand.

Here's a table showing the aluminum production capacity in tons per year for major U.S. companies at different times:

| Jan 1951 | Dec 1952 | Jan 1956 | |

|---|---|---|---|

| Chalmette | 100,000 | 200,000 | |

| Mead | 145,000 | 175,000 | 175,000 |

| Tacoma | 25,000 | 33,200 | 33,200 |

| Totals | |||

| Alcoa | 368,750 | 568,750 | 706,500 |

| Reynolds | 231,500 | 359,500 | 414,500 |

| Kaiser | 170,000 | 308,200 | 408,200 |

| Anaconda | 60,000 | ||

| Bessie Coleman |

| Spann Watson |

| Jill E. Brown |

| Sherman W. White |