Lacquer facts for kids

Lacquer is a special kind of hard and often shiny coating. It is put on things like wood or metal to protect them and make them look good. Long ago, people made lacquer from the sap (liquid) of certain trees and waxes.

In Asia, "true lacquer" is made from the treated sap of trees like the lacquer tree. This sap is put on objects, usually made of wood, in many thin layers. Each layer is dried carefully. When finished, it creates a very hard, smooth, and shiny surface. This surface is strong, waterproof, and feels nice to touch. Asian lacquer is often decorated with paintings, carvings, or gold dust.

Today, the word "lacquer" can also mean a range of clear or colored coatings. These modern lacquers dry as their solvents (liquids that dissolve other substances) evaporate. They create a tough, lasting finish. Lacquer finishes can be very dull (matte) or very shiny (glossy). They are usually harder than regular paints. People often use them on smooth, hard surfaces.

Some modern finishes are called shellac or lac. These are made from shellac dissolved in alcohol. Other modern lacquers are called "synthetic lacquer." These are made from man-made materials like nitrocellulose or acrylic resin. They are dissolved in a mix of organic solvents. Synthetic lacquer is usually stronger than shellac. However, traditional shellac finishes are still liked for their natural look and feel. They are also often safe for food.

Contents

Where the Word "Lacquer" Comes From

The English word "lacquer" comes from an old French word, lacre. This word meant "a type of sealing wax." It then came from Portuguese, Arabic, and Persian words. Finally, it traces back to a Sanskrit word, lākshā. This word meant the lac bug. This insect produces a resin that was used as a wood finish in ancient India.

Natural Lacquers: Shellac and Urushiol

Shellac-Based Lacquers

In India, shellac has been used for a very long time. Shellac is a sticky substance made by tiny insects called lac bugs. People use it to finish wood, make lacquerware, and even for cosmetics. It is also used to make dyes for clothes.

Urushiol-Based Lacquers

Urushiol-based lacquers are different from most others. They dry slowly and harden through a chemical process called oxidation and polymerization. This means they react with oxygen and form strong chains. The main part of this lacquer is urushiol, which is a mix of natural chemicals from tree sap. For it to dry properly, it needs a warm and humid place.

These lacquers create very hard and strong finishes. They are beautiful and can resist damage from water, acids, and scratches. The sap comes from trees found in East Asia, like the lacquer tree. The fresh sap from these trees can cause a skin rash, so people need to be very careful when working with it. Lacquer skills became very advanced in Asia. Many beautiful and decorated items were made.

The lacquer tree has been in Japan for a very long time, almost 12,600 years. This was found by studying old lacquer trees. Lacquer was used in Japan as early as 7000 BCE. The oldest lacquerware was found in Hokkaido, Japan. It included ornaments made with red lacquered thread.

In China, during the Shang dynasty (1600–1046 BC), people developed advanced ways to use lacquer. It became a high art form. Even older lacquerware has been found in China from the Neolithic period. The oldest known Chinese lacquer object is a red wooden bowl. It was found at a site from the Hemudu culture (5000–4500 BC). By the Han dynasty (206 BC – 220 AD), many places in China were making lacquer. The knowledge of Chinese lacquer making spread to Korea and Japan.

Lacquer objects were traded to the Middle East. In China, lacquer was used for coffins, musical instruments, furniture, and household items. Red lacquerware from China is made by mixing lacquer with powdered cinnabar.

From the 1500s to the 1600s, lacquer was brought to Europe in large amounts. This happened through trade with Japan. Until the 1800s, lacquerware was one of Japan's main exports. European royalty and rich people collected Japanese lacquerware. These items were often decorated with beautiful maki-e designs. Words related to lacquer, like "Japanning" and "Urushiol," came from Japanese.

The trees that give lacquer must be at least ten years old before their sap can be collected. The sap hardens by absorbing oxygen. Placing it in a humid place helps it absorb more oxygen from the water in the air.

Lacquer trees in Thailand, Vietnam, and Burma are a bit different. Their sap contains similar substances called laccol or thitsiol. The lacquer from these trees is similar but softer than Chinese or Japanese lacquer. Burmese lacquer dries slower. It is often painted by hand without brushes.

Raw lacquer can be colored by adding small amounts of iron oxides. These can make it red or black. There is some proof that lacquer was used over 8,000 years ago in Japan and China. Later, people added other colors. Lacquer is not just a finish. If mixed with clay and applied to a mold with cloth, it can create objects without needing a wooden core. This process is called "kanshitsu" in Japan. For the Chinese musical instrument, the guqin, lacquer is mixed with deer horn powder. This makes it stronger for playing.

Different Kinds of Natural Lacquer

Natural lacquers can be divided into two main groups: unprocessed and processed.

The basic unprocessed lacquer is called raw lacquer. It comes directly from the tree, with only impurities filtered out. Raw lacquer has about 25% water and looks light brown. There is a standard type from Chinese lacquer trees. This is usually used for the first layers, mixed with powder. A high-quality type from Japanese lacquer trees is used for the final shiny layers.

Processed lacquer is made by stirring raw lacquer until much of the water evaporates. There are many different types of processed lacquer. For example, some are clear and can be mixed with colors. Others are already mixed with iron to make black lacquer. Some are mixed with a yellow substance to create a yellow-tinted lacquer. These are often used for middle layers. Japanese processed lacquers are often used for the top layers.

Some processed lacquers have oil added to them to make them extra glossy. Other special lacquers are very thick. They are mainly used for sticking gold or silver leaf onto objects.

Modern Lacquers

Nitrocellulose Lacquers

In the 1800s, new lacquers appeared. These were made with nitrocellulose, a material from cotton. They were used on brass items, like musical instruments. In the early 1920s, even faster-drying and stronger versions were made. These new lacquers quickly replaced older, slower-drying paints. They were used a lot in the car industry for about 30 years. Before these, car finishes had limited colors, damaged easily, and took a long time to dry.

One challenge with nitrocellulose was that it was very thick. It needed a lot of thinner liquid to be applied. This left a very thin layer that wasn't strong enough for outdoor use. Scientists found ways to make it less thick by heating it.

In 1923, the Oakland car brand was the first to use one of these new fast-drying nitrocellulose lacquers. It was a bright blue color. By 1925, nitrocellulose lacquers were changing the way cars, appliances, furniture, and musical instruments were finished.

Nitrocellulose lacquers are also used to make firework fuses waterproof. Each new coat of lacquer dissolves some of the previous coat. These lacquers were a big improvement for car and furniture finishes. They were easier to apply and kept their color better. The best way to apply them was by spraying. This led to the first widespread use of spray guns. Nitrocellulose lacquers create a hard, flexible, and strong finish that can be polished to be very shiny.

However, there are some downsides. The solvents used are flammable and can be harmful. Also, nitrocellulose itself is related to materials used for explosives. But after about a month, most of the harmful solvents evaporate, and the lacquer becomes much safer.

Acrylic Lacquers

In the 1950s, lacquers made with acrylic resin were developed. Acrylic resin is a clear, man-made plastic. Acrylic is also used in enamel paints, which get shiny without needing to be polished. But enamels dry slowly. The great thing about acrylic lacquer is how fast it dries.

Lacquers are not used as much for car finishes anymore. This is because tougher, more durable coatings called polyurethane were developed. These new coatings are better at resisting weather and chemicals. Modern car finishes usually have a primer, a color coat, and a clear topcoat.

Water-Based Lacquers

Because of health and environmental concerns with solvent-based lacquers, a lot of effort has gone into making water-based lacquers. These lacquers are much less harmful and better for the environment. They often give good results.

Water-based lacquers have fewer harmful fumes and are not as flammable as solvent-based ones. They still dry quite quickly. Even though their smell is weaker, they can still release tiny particles into the air. So, it's still important to wear protective gear. More and more, water-based colored lacquers are replacing solvent-based ones in cars and other industries. They are also used a lot for finishing wood furniture.

One challenge with water-based lacquer is that it can react strongly with other fresh finishes. For example, it might react with quick-dry primers or some paints. Also, stains from wood (like tannins) can sometimes bleed through the lacquer. If this happens, it's hard to fix because the lacquer reacts so much with other products. Water-based lacquer used for wood furniture is also usually not made for outdoor use, unless it says so specifically.

Japanning: European Imitation Lacquer

Just like "china" is a common name for porcelain, "japanning" was an old name for how Europeans tried to copy Asian lacquerware. When Asian lacquer work became popular in Europe in the 1600s, Europeans developed their own ways to imitate it.

The European method, used on furniture and other items, uses finishes similar to shellac. This technique, called japanning, involves putting on several layers of varnish. Each layer is dried with heat and then polished. In the 1700s, japanning became very popular. It was often used as a black coating for metal items. By the 1900s, the term "japanning" was used for coatings made from various varnishes and lacquers, not just shellac.

Images for kids

-

A Chinese carved lacquer oval tray, Yuan dynasty, c. 13th century.

-

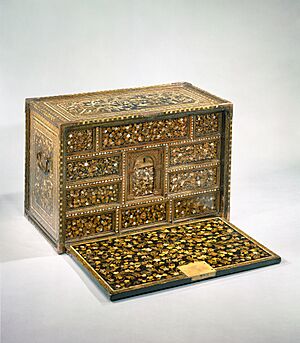

Ming dynasty Chinese lacquerware container, dated 16th century.

-

Inro in maki-e Lacquer, Edo period Japan, 18th century

-

Picnic Box with Design of the Scene from The Tale of Genji in Maki-e Lacquer, Edo or Meiji period Japan, 19th century

-

Lacquered vases from B.Thulhaadhoo, Maldives.

See also

- Lacquerware

- Varnish

- Acetate disc

- Cupping tester

- Lacquer painting