Lochaber Narrow Gauge Railway facts for kids

Quick facts for kids Lochaber Narrow Gauge Railway |

|

|---|---|

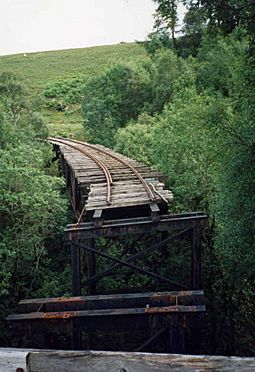

Bridge number 15 on the closed Upper Works Railway, photographed in 1995

|

|

| Overview | |

| Locale | Scotland 56°49′19″N 4°43′16″W / 56.822°N 4.721°W Headquarters: Fort William |

| History | |

| Opened | 1925 |

| Closed | 1977 |

| Technical | |

| Line length | 25 mi (40 km) |

| Track gauge | 3 ft (914 mm) |

The Lochaber Narrow Gauge Railway was a special kind of industrial railway in Scotland. It used a 3 ft (914 mm) narrow-gauge track, which means the rails were closer together than on regular trains. This railway was quite long, built to help construct and then maintain a huge 15-mile-long (24-kilometre) tunnel.

This tunnel carried water from Loch Treig to a factory near Fort William. The water power was used to make aluminium for a company called British Aluminium. People often called this railway the 'Old Puggy Line'.

Contents

Making Aluminium and the Need for Power

Aluminium is a metal found in a clay-like rock called bauxite. To get pure aluminium, you need a lot of electricity. The first factory in the UK to do this opened in 1896 at Foyers.

Later, another factory opened in 1908 at Kinlochleven. It used water power from the Blackwater Reservoir. As more and more aluminium was needed, British Aluminium planned a new factory. They chose Fort William because it had plenty of water power.

The plan was to build a 15-mile (24 km) tunnel. This tunnel would bring water from Loch Treig to the new factory. Smaller streams along the tunnel's path would also feed water into it. The new factory, called the Lochaber Works, was approved in 1921.

Building the Railway

The first part of the project took five years to build, starting in the mid-1920s. It cost a lot of money, about £3 million. Big engineering companies like Messrs Meik and Halcrow and Balfour Beatty worked on it.

To power the drills, pumps, and lights needed for construction, a temporary power station was built. This station used water to create electricity. About 25 miles (40 km) of power lines carried this electricity to different parts of the building site.

A temporary railway was also built to move materials around the power station site. It was probably a 2 ft (610 mm) gauge railway. Materials arrived by train on the main railway line and were then moved to this smaller railway.

Getting Materials to the Site

To bring in all the building materials, a temporary jetty was built where the River Lochy met Loch Linnhe. Later, a stronger concrete pier was constructed. This pier was about 0.5 miles (0.8 km) long.

A 3 ft (914 mm) gauge railway connected this pier to the factory site, which was called 'base camp' at the start. Engineers knew a railway was essential to connect all the work sites along the 17-mile (27 km) tunnel route.

The railway helped move workers and materials to 23 different places where tunnelling was happening. This was important because there were no roads to these remote sites. The railway from the factory eastwards to Loch Treig was called the Upper Works Railway.

Challenges of Building the Track

Building the railway was not easy. The land was very hilly. For example, Base Camp was at 35 feet (11 m) above sea level, but Adit 10 (a tunnel entrance) was at 640 feet (200 m). This meant the railway had to climb steeply in places. Some parts had a slope of 1 in 25, which is very steep for a train!

The railway also crossed soft, marshy areas called peat bogs. Here, the tracks were laid on bundles of brushwood called fascines. This made the track a bit wobbly. Teams of workers used shovels and pickaxes to level the ground for the railway.

Different Parts of the Railway

The Pier Railway was meant to be permanent. It used heavy rails. Its route was changed later to avoid the new village of Inverlochy. The new Pier Railway was about 2 miles (3.2 km) long. It crossed the West Highland Railway and the A82 road using bridges. The older railway had crossed the road at ground level.

The Upper Works Railway used lighter rails because it was originally planned to be temporary. Workers built many wooden bridges over streams. For bigger ravines, like at Bridge 15 and Bridge 27, they used strong steel spans supported by concrete pillars.

Inside the tunnel, there was also a 2 ft (610 mm) gauge railway. This smaller railway helped remove rock and dirt from the tunnel. It was mostly single track, but had sidings at the tunnel entrances to move wagons. Once the tunnel was finished, this railway was removed.

The Railway System

The main area of the railway was at the factory, or 'Base Camp'. Here, there were sheds for locomotives and other equipment. Some tracks here were mixed gauge, meaning they had both 3 ft/914 mm narrow gauge and 4 ft 8 1⁄2 in/1,435 mm standard gauge standard gauge rails.

The railway was a network of different lines:

Pier Railway

The Pier Railway was built to bring construction materials from a pier on Loch Linnhe to the factory site. It was about 1.75 mi (2.82 km) long. The first part had two tracks and crossed the Water of Nevis.

This railway crossed over the main London and North Eastern Railway line and the A82 road on bridges. The factory area had many buildings, including workshops, stores, and a locomotive shed. There were also huts for 700 workers.

Around 1939, a new Pier Railway was built. It crossed the main Fort William railway line and the A82 road on bridges. This new line was used to bring alumina (a material for aluminium) to the factory and to send finished aluminium ingots away by ship.

Upper Works Railway

The Upper Works Railway was the longest part of the system, running for about 19 miles (31 km) from the factory to the valve shafts near Loch Treig. The first part of this railway climbed very steeply.

Most of the bridges on this line were first made of wood. But later, they were rebuilt using strong steel from the factory. In the middle of the railway, at a place called "Central," there was a special track layout called a triangle to turn trains around.

There were also three shorter branch lines on the Upper Works Railway. One was the portal incline railway, which climbed steeply using an electric winch. Other branches went to Adit 10 and Adit 7, which were other tunnel entrances.

Treig–Laggan Railway

This was another branch line, about 3+1⁄4 mi (5.2 km) long. It was built in 1930 and connected the Upper Works Railway to Laggan Dam on Loch Laggan. This branch crossed over the West Highland Railway at Fersit on a long wooden bridge. Over time, much of this bridge was filled in with earth to make an embankment.

Closure of the Railway

In October 1971, heavy rain caused part of the Upper Works Railway to be washed away. There was a gap of about 70 ft (20 m) in the track. After this, the company decided it would be better to build new roads instead of fixing the railway.

However, it took a while to build the new roads. So, the railway kept running for several more years. Two locomotives and two smaller inspection cars were stuck on the other side of the damaged track. The railway finally closed down in 1977.

What Remains Today

After the railway closed, most of the tracks were removed. But many of the steel bridges were left in place. You can still find some short pieces of track on some of the longer bridges.

Some of the old 3-foot gauge trains and equipment still exist! One locomotive, named 'Sir Murray Morrison', was rebuilt and now works on the Cavan and Leitrim Railway in Ireland. Other inspection cars and wagons are also preserved.

In 2005, there was talk about reopening part of the Upper Works Railway as a tourist attraction.

See also

- British industrial narrow-gauge railways

| William L. Dawson |

| W. E. B. Du Bois |

| Harry Belafonte |