Lynton and Lynmouth Cliff Railway facts for kids

The Lynton and Lynmouth Cliff Railway is a special kind of railway called a funicular. It uses water to power its movement! This railway connects two towns, Lynton and Lynmouth, which are located on a very steep coast in North Devon, England.

Lynton and Lynmouth are separated by a tall cliff. This made it really hard for people and goods to travel between them. In the late 1800s, people started thinking about building a funicular or a cliff lift to make travel easier. A clever engineer named George Croydon Marks helped design it and found money for the project with his business partner, Sir George Newnes. A local builder, Robert Jones, also helped design the railway's unique braking system and worked on building and maintaining the line for many years.

Construction began in 1887. A year later, a special law was passed that allowed the Lynmouth & Lynton Lift Company to run the railway. The completed railway opened on Easter Monday in 1890. It has been working continuously ever since! At first, it was mainly used to move heavy items like coal. But soon, it became very popular with tourists, and it's now mostly used for passengers. In 1947, its flat platforms were changed into proper passenger carriages. This railway is known as the world's highest and steepest water-powered cliff railway that is still in use.

Contents

History of the Cliff Railway

Why the Railway Was Needed

The tall cliffs between Lynton and Lynmouth made it difficult for people to travel and for businesses to grow. Most goods, like coal, lime, food, and other important supplies, arrived by sea at Lynmouth. Then, they had to be carried by packhorses and carts up the very steep hill to Lynton.

The cliffs also caused problems for the growing tourism industry. Holidaymakers would arrive at Lynmouth on paddle steamers from places like Bristol and Swansea. This started around 1820. You could hire ponies, donkeys, and carriages, but the steep hills meant the animals didn't last long. As the 1800s continued, it became clear that the cliffs were making it hard to move goods and were stopping new visitors from coming.

In 1881, ideas for a tramway or a rail-based lift came up. One plan involved using a stationary steam engine at Lynton, but it didn't go ahead. In 1885, another idea for a pier and cliff lift was suggested.

Building the Railway

In 1888, a special law allowed the Lynmouth & Lynton Lift Company to be formed. This law also gave them the right to take a lot of water (up to 272,760 litres) from the Lyn Valley river every day.

The water-powered railway was designed by a civil engineer named George Croydon Marks. Most of the money for building it came from his business partner, Sir George Newnes. Sir George owned a big house nearby and also supported other projects like the Lynton and Barnstaple Railway and the building of Lynton Town Hall. Robert Jones was hired as the main builder for the cliff railway. He also helped design parts of the system.

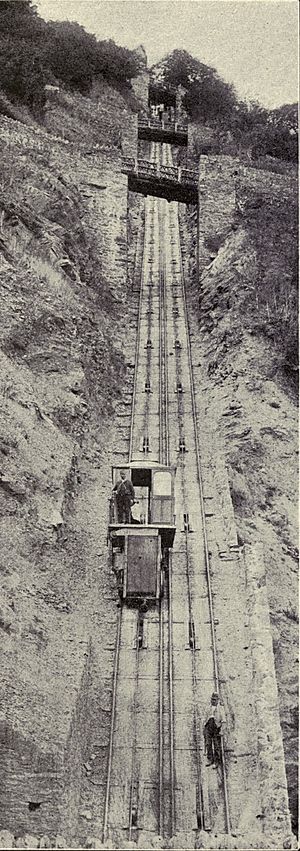

Construction began in 1887. Workers dug a cutting (a channel) into the limestone cliff to create the track. Three bridges were built over this track to carry existing paths. All the work was done by hand. The railway was finished in February 1890. Robert Jones continued to work as the company's engineer until 1921.

How the Railway Works Today

The cliff railway opened on Easter Monday, April 7, 1890. It has been running without stopping ever since! It quickly became useful for carrying many different things, including coal, ice, sand, and even petrol. The original cars were flat platforms that could have passenger carriages placed on them.

One interesting feature is a small stop, or halt, just below Lynton station. You can reach it by road. Large items, even motor cars, were moved by the railway until the late 1950s. When the tracks were replaced in 2006, this halt was used to access the site and store materials.

In June 1995, the waiting rooms at the top and bottom stations were given a special status as Grade II listed buildings. This means they are important historical structures. On September 18, 2014, the Institution of Mechanical Engineers (IMECHE) recognized the railway as a unique and amazing example of British engineering. It was the first public water-powered funicular railway in the UK that uses a "total-loss" system (meaning the water isn't reused).

In April 2018, the cliff railway had to close briefly for safety checks. This happened after a landslip (when a mass of earth slides down a slope) occurred near the middle bridge. The landslip was caused by heavy rain, freezing weather, and strong winds. Debris fell onto the track, but luckily, the railway was not running at the time.

Technical Details of the Railway

The railway has two cars, and each can carry up to 40 passengers. They are connected by cables that run up and down. These cables go around large 5 ft 6 in (1.676 m) pulleys at each end of the slope. This setup helps balance the weight of the cables. Originally, there was only one cable, but later, two cables were used, probably for extra safety. The cars don't need any power to move themselves. This system also has a very low carbon footprint, which is good for the environment.

Water travels over 1 mile (1.6 km) from the West Lyn River through 5-inch (127 mm) wide pipes. It goes to a storage tank at the top station. Each car has a 700-imperial-gallon (3,182 L; 841 US gal) tank between its wheels. When the car going down reaches the bottom station, its tank is emptied. Then it's ready for the trip back up. Once passengers are on board at both stations, water is added to the tank in the upper car. When it's heavy enough, it starts to go down, pulling the lower car up the hill.

As the car goes down, its speed is controlled by a driver in each car. They use hand signals to work together. Because the railway is so steep, the original carriages had four different braking systems. The main system uses water to squeeze special clamps onto the rails. There are also other brakes that press steel shoes onto the rails. What's unique is that this railway uses water instead of oil for its main hydraulic brakes. In June 1888, the braking system was patented by Newnes, Jones, and Marks.

The two parallel tracks are 3 ft 9 in (1,143 mm) wide. They climb 500 feet (152.4 m) and are 862 feet (262.7 m) long. This gives the line a very steep gradient of 1:1.724 (which means it goes up 1 unit for every 1.724 units forward, or 58% steepness). Halfway up the slope, there's a wider section where the tracks separate a bit, allowing the cars to pass each other. The track uses a type of rail called Bullhead rail. Originally, wooden sleepers (the pieces of wood or concrete that support the rails) were bolted to the rock. These wooden sleepers have now been replaced with modern concrete ones.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |