Martin-Baker facts for kids

|

|

| Private | |

| Industry | Aircraft ejection systems |

| Founded | 1934 |

| Founder | Sir James Martin Valentine Baker |

| Headquarters | Denham, Buckinghamshire, England |

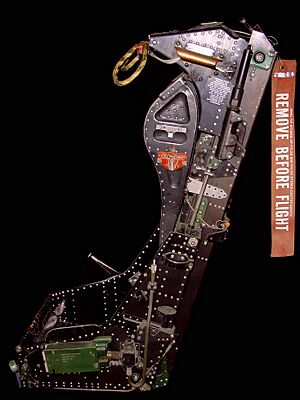

Martin-Baker Aircraft Company Limited is a British company famous for making ejection seats. These special seats help pilots escape from aircraft in emergencies. The company also makes other safety equipment for planes and helicopters.

Martin-Baker started out building aircraft. Later, they became leaders in designing and making ejection seats. Their main office is in Denham, England. They also have locations in France, Italy, and the United States.

This company provides ejection seats to 93 air forces around the world. Their seats are used in over 200 different types of aircraft. This includes modern jets like the Lockheed Martin F-35 Lightning II.

Martin-Baker announced in 2022 that their ejection seats have saved 7,789 lives. This count started after their first live ejection test in 1945.

The company also makes "crashworthy" seats. These seats are designed to protect people in helicopters and other aircraft during a crash. By 2012, they had delivered over 20,000 of these special seats. Martin-Baker is still a family-run business. It is managed by the twin sons of the founder, Sir James Martin.

Contents

- The Story of Martin-Baker

- How Ejection Seats Work

- Types of Martin-Baker Ejection Seats

- Martin-Baker Mk.1

- Martin-Baker Mk.2

- Martin-Baker Mk.3

- Martin-Baker Mk.4

- Martin-Baker Mk.5

- Martin-Baker Mk.6

- Martin-Baker Mk.7

- Martin-Baker Mk.8

- Martin-Baker Mk.9

- Martin-Baker Mk.10

- Martin-Baker Mk.11

- Martin-Baker Mk.12

- Martin-Baker Mk.14 NACES (SJU-17)

- Martin-Baker Mk.15

- Martin-Baker Mk.16

- Martin-Baker Mk.17

- Martin-Baker Mk.18

- Testing and Operations

- The Ejection Tie Club

- Important Safety Incident

The Story of Martin-Baker

The company began in 1929 when James Martin set up "Martin's Aircraft Works." In 1934, James Martin and Captain Valentine Baker officially formed the Martin-Baker Aircraft Company. They wanted to develop new aircraft designs.

Martin and Baker first designed an unusual two-seat plane called the MB 1. This project was stopped because of money problems. They also built an autogyro, which is like a helicopter with a spinning wing.

In 1935, they flew their own plane, the Martin-Baker MB 1. Their first military plane was the Martin-Baker MB 2 fighter, which flew in 1938. It was designed to fly in hot places.

Early Aircraft Designs

- Martin-Baker MB 3 (1942): This was a fighter plane with six cannons. Sadly, Captain Baker died in a crash while testing this plane.

- Martin-Baker MB 4 (1943): This fighter plane design was canceled before it was built.

- The Martin-Baker MB 5 (1944): This plane was a redesigned version of the MB 3. It had a strong steel body and special propellers.

- Martin-Baker MB 6 (1945): This was a jet fighter project from World War II. It included an early idea for an ejection seat.

- Martin-Baker MB 7 (1946) Black Bess: This was a concept for a fast test aircraft after the war. The project was stopped in 1947.

During World War II, Martin-Baker made parts for aircraft. They also designed special cutters for bomber wings. These cutters helped planes get free from barrage balloon cables, saving many aircraft.

In 1944, the British government asked the company to research ejection systems. They wanted to find a way for pilots to safely escape from fast fighter planes.

How Ejection Seats Work

Martin-Baker started looking into ejection seats as early as 1934. They decided that an explosive charge was the best way to launch a seat. Captain Baker's death in 1942 made James Martin focus even more on pilot safety. This led the company to specialize in ejection seats.

In 1944, James Martin was asked to develop ways for fighter pilots to escape. He believed the best method was to eject the pilot and their seat using an explosive charge. After ejecting, the pilot would separate from the seat and open their parachute.

To figure out how much force a person could handle, they built a special test rig. This rig was like a tall tripod. A seat was shot up guide rails using an explosive cartridge.

On January 20, 1945, they did the first test with a dummy. Four days later, a company worker named Bernard Lynch did the first "live" test. He was shot up the rig to a height of about 1.4 meters (4 feet 8 inches). They slowly increased the power until he reached 3 meters (10 feet). At this point, Lynch felt a lot of discomfort.

The first real ejection seat was successfully tested by Bernard Lynch on July 24, 1946. He ejected from a Gloster Meteor jet flying at 515 kilometers per hour (320 mph) at 2,438 meters (8,000 feet) over Chalgrove Airfield.

The first production Martin-Baker ejection seat was installed in the Saunders-Roe SR.A/1 prototype plane.

Martin-Baker was a leader in making ejection seats work at very low altitudes and speeds. This led to the "zero-zero" capability in 1961. A "zero-zero" seat can save a pilot even if the plane is on the ground and not moving.

Types of Martin-Baker Ejection Seats

Martin-Baker has developed many different models of ejection seats over the years. Each "Mk." (Mark) number represents a different design or improvement. Here are some examples of the aircraft that use these seats:

Martin-Baker Mk.1

- Avro Canada CF-100 Canuck

- English Electric Canberra

- Gloster Meteor

- Hawker Hunter

Martin-Baker Mk.2

- Avro Canada CF-100 Canuck

- de Havilland DH.112 Venom

- English Electric Canberra

- Gloster Meteor

Martin-Baker Mk.3

- Avro Vulcan

- Fairey Delta 2

- Gloster Javelin

- Handley Page Victor

Martin-Baker Mk.4

- Aermacchi MB-326

- Dassault Mirage III

- English Electric Lightning

- SEPECAT Jaguar

Martin-Baker Mk.5

- Douglas F4D Skyray

- Grumman A-6 Intruder

- Lockheed T-33 Shooting Star

- McDonnell F3H Demon

Martin-Baker Mk.6

Martin-Baker Mk.7

- Grumman F-14 Tomcat

- Lockheed F-104 Starfighter

- McDonnell Douglas F-4 Phantom II

- Northrop F-5

Martin-Baker Mk.8

- Embraer EMB 312 Tucano

- BAC TSR-2

Martin-Baker Mk.9

- Hawker Siddeley Harrier

- SEPECAT Jaguar

Martin-Baker Mk.10

- BAE Systems Hawk

- Dassault Mirage 2000

- Dassault Rafale

- McDonnell Douglas F/A-18 Hornet

- Panavia Tornado

- Saab JAS 39 Gripen

Martin-Baker Mk.11

- Pilatus PC-7 Turbo Trainer

- Pilatus PC-9

Martin-Baker Mk.12

- Hawker Siddeley Harrier

Martin-Baker Mk.14 NACES (SJU-17)

This seat is used by the US Navy.

Martin-Baker Mk.15

- Pilatus PC-7 Mk II

Martin-Baker Mk.16

- Alenia Aermacchi M-346 Master

- Beechcraft T-6 Texan II

- Eurofighter Typhoon

- Lockheed Martin F-35 Lightning II

- Pilatus PC-21

Martin-Baker Mk.17

This is a very small and light ejection seat.

- Grob G 120TP

Martin-Baker Mk.18

- KAI KF-21 Boramae

Testing and Operations

Martin-Baker has its own airfield, Chalgrove Airfield, in Oxfordshire, England. They use this airfield to test their ejection seats. They even fly their special Meteor test planes from Chalgrove to France for some tests.

Two Gloster Meteor T.7 aircraft, WL419 and WA638, are still used by the company for flight testing. Another Meteor plane (WA634), which helped develop early ejection seats, is now at the Royal Air Force Museum Midlands.

The Ejection Tie Club

Martin-Baker runs a special "Ejection Tie Club." If your life has been saved by one of their ejection seats, you can become a member! Members receive a special tie, patch, certificate, and membership card. The company also worked with Bremont to create a special watch for club members.

The club started in 1957. As of 2019, there are over 6,000 registered members.

Important Safety Incident

In 2011, a pilot from the Red Arrows display team, Flt. Lt. Sean Cunningham, was involved in an incident on the ground. He was ejected from his Hawk T1 jet. Sadly, his parachute did not open.

In 2018, Martin-Baker admitted that they had not properly warned the Royal Air Force about a technical issue with a bolt on the ejection seat. The company stated they had known about this problem since 1990. They admitted that they failed to provide a written warning about over-tightening this bolt.

| Precious Adams |

| Lauren Anderson |

| Janet Collins |