Reșița Works facts for kids

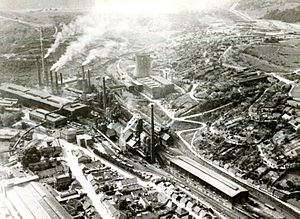

The Reșița Works are two important companies, TMK Reșița and UCM Reșița. They are located in Reșița, a city in the Banat region of Romania. These factories started way back in 1771. For a long time, they worked as one big company. During the time of Communist rule, they were known as the Reșița Steel Works and the Reșița Machine Building Plant. These factories have been super important for the growth of industry in Romania and the local area. Their story is closely linked to the story of Reșița city itself.

Contents

History of the Reșița Works

How it All Started and Grew

The Habsburg monarchy, which ruled the Banat region, wanted to make more metal. So, in 1769, they began building furnaces in Reșița to melt iron ore. The factories officially started on July 3, 1771. This makes them the oldest industrial factory still operating in Romania today!

At first, the main work was shaping metal. But over time, making machines became more important. By the late 1800s, machine manufacturing was the main job. For many years, both metalworking and machine making worked together in the same factory. Until 1855, the factories belonged to the government's Treasury.

By 1815, the Reșița Works were making many things. They produced cast iron parts, iron rods, hoops for cart wheels, tools, nails, and items for farms and homes.

A New Owner and Big Plans

In 1855, the government sold the factories because it needed money. An international group called the Imperial Royal Privileged Austrian State Railway Company bought them. This company also owned land, mines, metal factories, and railways. They even had a factory in Vienna that made locomotives (train engines). There's a story that metal from Reșița was used to build the Eiffel Tower in Paris in the late 1880s. But there's no proof that this actually happened.

A big reason for the factories' success was that they could mostly supply themselves. They often used raw materials and energy sources that were found or made right there.

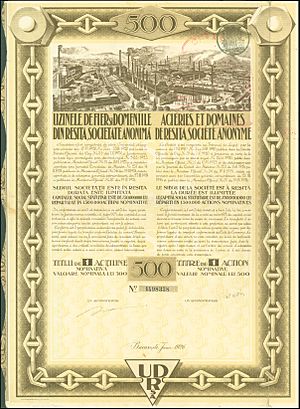

After the Banat region joined Romania, a new company was formed in 1920. It was called the Steel Works and Domains of Reșița (U.D.R.). A special area for workshops was built near the Bârzava River. This area included the machine works, where the first workshops were built between 1886 and 1891. Most of the company's land was forests. But they also had mines for iron, coal, and copper, as well as vineyards and quarries for limestone.

What the Factories Made

Starting in the 1920s, the Reșița Works had many different parts:

- Furnaces for melting metal

- A plant for making coke (a type of fuel)

- Steel factories

- Mills for rolling metal

- A foundry (for casting metal)

- A forge (for shaping metal with heat)

- Factories for bridges and metal structures

- A factory for train wheels

- An old machine factory

- A factory for oil drilling equipment

- A factory for weapons

- A factory for electric machines

- A factory for locomotives, which could make 100 train engines a year.

Some of their main products included:

- Steam locomotives (train engines)

- Train wheels and axles

- Metal bridges and railway equipment

- Metal frames for buildings

- Moveable bridges

- Electric machines like motors and generators

- Equipment for drilling oil, such as pumpjacks

- Weapons like artillery, anti-tank guns, and mortars.

The Reșița Works was the largest company in Romania in terms of money earned and the number of people it employed. In 1948, it had 22,892 employees! In 1939, after Nazi Germany took over parts of Czechoslovakia, they also took control of a share in Reșița. This made it harder for the King of Romania, Carol II, to keep Romania independent. Later, a German company took over the business and technical management.

Nationalization and Changes

In June 1948, the new Communist government took control of the company. This was part of a big plan to take over many companies in Romania. For about a year, it kept its old name. But then, in 1949, it was split into two parts. This was the first time the Reșița Works were divided.

In 1954, the two parts were put back together into one big company. It was called the Reșița Metallurgical Works. Even though it remained very important, some parts of the Reșița Works were gradually shut down. For example, the factories for metal structures, oil drilling equipment, and train switches were closed.

However, new and advanced technologies were also brought in. They started making:

- Steam turbines and turbo generators

- New air compressors

- Diesel locomotives

- Hydroelectric units (for making electricity from water)

- Diesel engines for ships

- Equipment for chemical and metal industries

- Fluid mechanics equipment like hydraulic pumps.

During this time, steam locomotives were stopped being made. For forty years, the Reșița Works played a big part in almost every major economic plan in Romania. This included programs for energy, nuclear power, rail transport, the navy, and the metal and chemical industries. Their products were also sent to nearly forty other countries around the world.

Splitting Up and Becoming Private Again

On April 1, 1962, the Reșița Works were split into two separate companies again. These were the Reșița Steel Works (CSR) and the Reșița Machine Building Plant (UCMR or UCM). They were meant to work together.

After the Communist government fell in 1989, the Steel Works (CSR) started to have problems. In 1994, thousands of workers and residents protested. This led to new investments and equipment. In 1996, CSR became a public company.

Its first attempt to become a private company in 2000 didn't work out. An American company took over but was accused of not keeping its promises. This caused many protests. Eventually, in 2001, the government decided to cancel the contract. The process started again in 2003. In 2004, the state sold the company. Since 2006, it has been known as TMK Reșița, and it is part of a Russian company. It makes special metal parts. By 2011, the number of employees had dropped to 800, from 10,400 in 1990.

The Machine Building Plant (UCMR) was controlled by different government ministries. Its name was changed in 1973 to Reșița Machine Building Enterprise (ICMR). Between 1969 and 1973, it was the main part of a group of factories in Reșița. After the Romanian Revolution, it got its UCMR name back in 1991. It became a private company in 2003. Today, it is mostly owned by a Swiss company and has about 2500 employees. It works on machining, welding, and heat treatments for metal.

Historic Landmarks and Environment

Four parts of the Reșița Works are listed as historic monuments. These include the UCM locomotive factory, and from the CSR, blast furnace #2, the brick factory, and a special workshop for puddling and steam laminating. Even though blast furnace #1 was taken down, blast furnace #2 was kept. It's important because it shows the city's history and its industrial past.

By the early 1990s, the factories had caused serious air, water, and soil pollution. This made Reșița one of the most polluted areas in Eastern Europe.

Images for kids

-

Workers welcoming Nicolae Ceaușescu and Ion Gheorghe Maurer (1968)

See also

- Galați steel works

- FAUR

Notes

Lua error in Module:Coordinates at line 614: attempt to index field 'wikibase' (a nil value).

ro:UCM Reșița

| Aaron Henry |

| T. R. M. Howard |

| Jesse Jackson |