Sand filter facts for kids

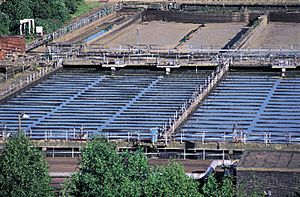

Sand filters are special filters that use sand to clean water. They are an important step in making water safe to drink or use.

There are three main kinds of sand filters:

- Rapid sand filters (which use gravity or pressure)

- Upward flow sand filters

- Slow sand filters

All these types are used a lot around the world to clean water. Rapid and upward flow filters often need special chemicals called flocculants to work best. Slow sand filters, however, can clean water very well without chemicals. They can remove most harmful germs (like pathogens) and even improve the water's taste and smell. Sand filters can be used in big water treatment plants or even at home, because they use simple materials.

Contents

How Sand Filters Began

People have used ways to separate things for a very long time. Even in ancient times, people used materials like rushes and plants to filter liquids. The ancient Egyptians used clay pots with tiny holes to filter their drinking water, wine, and other liquids. This shows that the idea of filtering water is very old!

How Sand Filters Clean Water

A sand filter is a type of "depth filter." This means it catches tiny bits of dirt and other particles inside a thick layer of material, not just on the surface. Think of it like a sponge that traps dirt inside its holes.

There are two main ways filters work:

- Surface filters catch particles on their top layer.

- Depth filters catch particles deep inside the material.

Sand filters are good at removing small amounts of tiny particles (less than 100 micrometers, which is super small!) from water. They are mostly used to clean the water itself, rather than collecting the particles. This is why they are often used in wastewater treatment.

How Particles Get Trapped

Sand filters work because water flows through many tiny spaces between the sand grains. As the water twists and turns, the small particles in the water get very close to the sand grains. They can get caught in a few ways:

- Direct hit: The particle bumps right into a sand grain and sticks.

- Sticky forces: Tiny forces (like Van der Waals forces) pull the particles onto the sand.

- Electric pull: Opposite electric charges can attract particles to the sand.

- Floating around: Very tiny particles might just drift into a sand grain and get stuck.

Sometimes, particles might not stick if they have the same electric charge as the sand. Also, particles that are already stuck might get knocked off, but they usually get caught again deeper in the filter.

To make sure particles stick well, water is sometimes treated before it enters the sand filter. This can be done by:

- Changing the water's pH level to adjust the electric charge of the particles and sand.

- Coagulation: Adding small chemicals (like aluminum or calcium) that have a strong electric charge. These chemicals help tiny particles clump together.

- Flocculation: Adding special long chains of chemicals that act like bridges, connecting particles to each other or to the sand, making bigger clumps.

Different Ways Sand Filters Operate

Sand filters can work with water flowing downwards (most common) or upwards. When water flows downwards, it can be pushed by pressure or just by gravity.

- Pressure sand filters are often used in factories and are called rapid sand filters.

- Gravity-fed filters are common for cleaning drinking water, especially in developing countries (these are called slow sand filters).

Here are the main types of sand filters:

- Rapid (gravity) sand filters

- Rapid (pressure) sand filters

- Upflow sand filters

- Slow sand filters

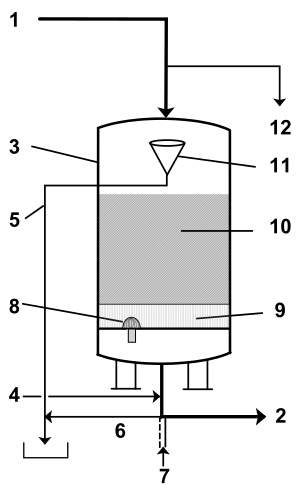

A rapid pressure sand filter usually has a big chamber filled mostly with sand. Dirty water comes in from the top, flows through the sand, and clean water leaves from the bottom. These filters often have systems to spread the water evenly and control air flow. Over time, smaller sand grains tend to stay at the top, and larger ones at the bottom.

When a filter first starts working, it gets better at cleaning water as more particles get caught. This is called "filter ripening." During this time, the water might not be perfectly clean yet.

Filters need to be cleaned to remove the trapped dirt. This is called "regeneration."

- For rapid filters, this is done by backwashing. Water (and sometimes air) is pumped backwards through the filter. This lifts the sand grains and washes away the trapped dirt. This dirty water is then sent to a settling tank.

- For slow sand filters, the cleaning method is called scraping. The top layer of sand, where most of the dirt and germs are, is carefully removed.

Rapid Pressure Sand Filter Design

Smaller sand grains clean water better because they have more surface area. But it also takes more energy to push water through them. Most rapid pressure sand filters use sand grains between 0.6 and 1.2 millimeters in size. If the dirty water has very large particles, they can block the filter quickly. These large particles should be removed before the water reaches the sand filter.

The sand layer in these filters is usually about 0.6 to 1.8 meters (2 to 6 feet) deep. This depth helps make sure the filter works well.

Rapid pressure sand filters typically operate with a water pressure of 2 to 5 bar. When the filter is clean, the pressure drop across it is very small. As dirt builds up, the pressure needed to push water through increases. When the pressure drop gets too high (around 0.5 bar), it's time to backwash the filter.

Backwashing involves pumping water backward through the filter until the sand lifts and mixes. This helps the sand grains rub together and release the trapped dirt. The dirty backwash water is then collected and treated. A small amount of sand can be lost during backwashing, so the filter might need new sand added sometimes.

Slow Sand Filter Design

As the name suggests, slow sand filters clean water much slower than rapid filters. The biggest difference is that the top layer of sand in a slow filter becomes biologically active. This means tiny living things (microbes) grow there. This microbial layer forms within 10 to 20 days after the filter starts working.

As water slowly trickles through the sand, this living layer helps trap and remove organic material, bacteria, viruses, and other tiny harmful organisms like Giardia and Cryptosporidium.

To clean a slow sand filter, the top layer of sand is removed by "scraping." This can be done when the sand is dry or even underwater. Slow sand filters are a good choice for places with limited money because they don't use chemicals and need little machinery. However, because they are slow and need more space, rapid sand filters are often used in growing communities.

Comparing Rapid and Slow Sand Filters

| Feature | Rapid Sand Filter | Slow Sand Filter |

|---|---|---|

| Speed of cleaning [meters/hour] | 5–15 | 0.08–0.25 |

| Sand grain size [mm] | 0.5–1.2 | 0.15–0.30 |

| Sand bed depth [meters] | 0.6–1.9 | 0.9–1.5 |

| How long it runs before cleaning | 1–4 days | 1–6 months |

| Time to start working well | 15 minutes – 2 hours | Several days |

| How it's cleaned | Backwashing | Scraping |

| Maximum dirtiness of raw water | Unlimited with proper pre-treatment | 10 NTU (a measure of cloudiness) |

Upflow Bed Filter Design

The continuously backflushing or upflow sand filter is a newer type. In this filter, the dirty water enters from the bottom, and the clean water comes out at the top. This reverse flow allows the filter to clean itself while it's still filtering water. This means less water is wasted and less cleaning time is needed.

Mixed Bed Filters

Filters that use different layers of filtering materials are called mixed bed filters or multimedia filters. While sand is common, other materials like anthracite (a type of coal), activated carbon, garnet, and ilmenite are also used.

- Anthracite is a hard, light material.

- Ilmenite and garnet are heavier than sand.

- Activated carbon can both filter and absorb bad tastes or smells.

These materials can be used alone or mixed. The different layers are always arranged by weight, with heavier materials at the bottom and lighter ones on top. This creates different pore sizes throughout the filter, which helps catch different types of particles.

A common mixed filter has anthracite on top, then sand, and then garnet, all supported by a layer of gravel at the bottom. These filters are usually 0.6 to 1 meter deep. If they are too deep, it takes too much pressure to push water through. If they are too shallow, they don't filter as well.

Like other filters, mixed bed filters need to be backwashed when they get too clogged. The backwash flow is usually much stronger than the normal filtering flow to lift the materials and wash away the trapped particles.

What Sand Filters Are Used For

Sand filters are used a lot in the water industry around the world. Rapid and upflow filters often need chemicals to work well, but slow sand filters can produce very clean water without them.

When water that has been treated with flocculants (chemicals that make dirt clump together) goes through a rapid gravity sand filter, the filter catches these clumps and the particles inside them. This greatly reduces the number of bacteria and removes most solid bits. If water has a bad taste or smell, a layer of activated carbon can be added to the sand filter to remove these issues.

Over time, sand filters get clogged with the trapped dirt or with a layer of living organisms (called "bioclogging").

- Slow sand filters are cleaned by scraping the top layer.

- Rapid sand filters are cleaned by backwashing (pumping water backward through them).

The dirty backwash water is usually sent to settling tanks, where the dirt settles out. This settled dirt is then thrown away. Sometimes, the clean water from the settling tank is sent back into the treatment process. In some places, the dirt (sludge) can even be used to improve soil. If filters are not cleaned properly, they can sometimes lead to dirty drinking water.

Sand filters are also sometimes used in sewage treatment as a final cleaning step. Here, the sand traps any remaining solid bits and bacteria. It also provides a place for bacteria to break down harmful nitrogen compounds, like ammonia and nitrates, into harmless nitrogen gas.

Sand filters are very useful because they combine many cleaning functions in one process, especially slow sand filters.

Benefits and Challenges

One great thing about sand filters is that they can be used for many different jobs. The various types (rapid, slow, upflow) also make them flexible for different needs. Sand filters are very good at removing color and tiny organisms from water. They are also quite simple, so their running costs are low. Their simplicity also makes it easier to automate them, meaning less human work is needed.

The main challenge with sand filters is that they can get clogged. When this happens, a lot of water is needed for backwashing. Also, rapid filters might need chemicals for pre-treatment. Slow sand filters usually need more land space, especially if the dirty water is very contaminated. However, despite these challenges, sand filters offer many benefits and are widely used.

Challenges in Using Sand Filters

When cleaning water, there are a few things to watch out for. Processes like filter ripening (when the filter first starts working) and backwashing affect not only the water quality but also how long the whole treatment takes. Backwashing also means some water is lost, which needs to be considered if a certain amount of water must be delivered to a community. The dirty water from backwashing also needs to be treated or disposed of properly.

From a chemical point of view, changes in the quality of the raw water and changes in temperature can affect how well the treatment process works right from the start.

Also, when designing sand filters, there's some uncertainty because models often assume sand grains are perfect spheres. But in reality, sand grains have different shapes. This affects how tightly they pack together, which then changes how water flows through the filter.

Where Sand Filters Are Used in Industry

Sand filters are used in many different industries and processes where water or wastewater needs to be cleaned very well.

Some places where sand filtration is used include:

- Making drinking water.

- Cleaning swimming pool water.

- Car washes.

- Treating groundwater.

- Slaughterhouses and food processing factories.

- Cleaning water used to cool machines.

- As a first step before other advanced water treatments like activated carbon filters or membrane systems.

- Removing iron from groundwater by first adding air and then filtering.

- Final cleaning of wastewater after metals have been removed.

- Cleaning wastewater from steel and metal production.

- Cleaning water with sand-blasting grit and paint particles, for example, at shipyards.

- In greenhouses, slow sand filters are used to disinfect drain-water.

- Filtering pollutants from stormwater runoff.

- In sewage treatment, they help break down nitrogen compounds.

See also

In Spanish: Filtro de arena para niños

In Spanish: Filtro de arena para niños

- American Water Works Association

- Water treatment

- Water purification

- Jewell water filter

| Isaac Myers |

| D. Hamilton Jackson |

| A. Philip Randolph |