Traditional brick factory facts for kids

A traditional brick factory is a place where people make bricks from mud without using modern machines. All the work is done by hand. These factories are different from modern ones that use lots of equipment. Bricks are strong building blocks used to create walls, houses, and other structures. They are one of the oldest and most lasting building materials.

Contents

A Look Back: History of Bricks

People have been making bricks for a very long time! The oldest bricks ever found were made from shaped mud. They date back to before 7500 BC. These ancient bricks were discovered in a place called Tell Aswad. Later, similar findings were made near the Tigris River and in Anatolia, close to Diyarbakır.

Other old bricks, from around 7000 to 6395 BC, were found in Jericho and Çatalhöyük. In the ancient Indus Valley city of Mehrgarh, mud bricks from 7000 BC have also been found. Even older, ceramic bricks were used as early as 4500 BC in early Indus Valley cities. This shows how important bricks have been throughout history for building.

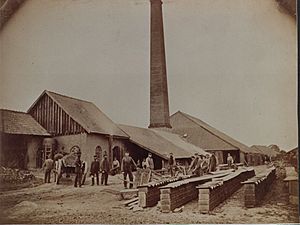

What's Inside a Traditional Brick Factory?

Most traditional brick factories have a few key areas:

- A kiln: This is a special oven used to bake or 'fire' the bricks. Baking makes them hard and strong.

- A drying yard or shed: This is where bricks dry in the open air before they go into the kiln.

- A yard for making bricks: This is the main area where workers shape the mud into bricks.

- A quarry: This is where the clay, which is the main material for bricks, is dug up from the ground.

- A pugmill or clay preparation area: This is where the clay is mixed and prepared.

How Bricks Are Made

In a traditional brick factory, the process starts with clay. Workers dig the clay from the quarry and carry it to the brick-making yard. Here, the clay is mixed and shaped into bricks. This can be done by hand or by pressing the clay into molds.

After the bricks are shaped, they need to dry. They are laid out in the open air or in special drying sheds. This step removes most of the water from the bricks. Once the bricks are dry, they are carefully moved to the kiln.

Inside the kiln, the bricks are 'fired' or 'burnt' at very high temperatures. This baking process gives them their final hardness, strength, and color. It's a bit like baking a giant clay cookie!

Bricks in Iran

Iran has a long history of making bricks by hand. There used to be about 300 traditional brick factories around Tehran, the capital city. However, most of them have now closed down. The use of traditional brick ovens and hand-pressed bricks is very old in Persia (ancient Iran). One famous ancient brick arch, called Taq-i Kisra, was built using these methods.

Tehran, which is 220 years old, has many old homes and historic buildings made with traditional bricks. Even modern buildings sometimes use them to keep a traditional look. But today, modern factories and new styles of bricks have mostly replaced the old hand-made ones. Only a few traditional factories are still working.

While traditional brick ovens are found all over Iran, the largest groups of hand-made brick kilns were historically around Tehran. Other cities like Isfahan, Yazd, Ahvaz, and Gonabad also had these types of factories.

What Bricks Are Made Of

Bricks are usually made from mud or clay. They contain several natural ingredients:

- Silica (sand): This makes up about 50% to 60% of the brick's weight.

- Alumina (clay): This is about 20% to 30% of the brick's weight.

- Lime: This is a smaller amount, about 2% to 5%.

- Iron oxide: This gives bricks their reddish color and makes up 5% to 6%.

- Magnesia: This is less than 1% of the brick.

Modern Ways to Bake Bricks

Even though this article is about traditional factories, it's good to know about modern methods too!

Rail Kilns

In modern brickworks, bricks are often baked in a special oven called a continuously fired tunnel kiln. Imagine a long tunnel where bricks slowly move through on conveyors or special cars. This movement helps all the bricks bake evenly. Sometimes, things like lime, ash, and other materials are added to the bricks to help them burn faster.

Bull's Trench Kilns

In India, making bricks is often still done by hand. A very common type of brick kiln there is called a Bull's Trench Kiln (BTK). This design was created by a British engineer named W. Bull in the late 1800s.

A Bull's Trench Kiln is an oval or circular trench dug into the ground. It's usually about 6–9 meters wide and 2-2.5 meters deep. A tall chimney stands in the middle. More than half of the trench is filled with "green" (unbaked) bricks. These bricks are stacked in a way that allows air to flow through them. The top of the stack is covered with a layer of finished bricks.

As the kiln operates, new green bricks are added at one end. Baked bricks are removed from the other end. In the middle, workers drop fuel like coal, wood, or oil through holes in the roof. This creates a hot zone that bakes the bricks as they slowly move through the trench.

Famous Brick Companies

Here are some well-known brick companies:

- The London Brick Company

- Brickworks Limited - an Australian brick maker

- Evergreen Brickworks

Related pages

Further Reading

- Hudson, Kenneth (1972) Building Materials; chap. 3: Bricks and tiles. London: Longman; pp. 28–42

- Dewan, Kader 2010

Images for kids