Baker's yeast facts for kids

Baker's yeast is the common name for special types of yeast used to bake bread and other yummy bakery items. It acts as a leavening agent, which means it makes bread rise and become light and soft. It does this by turning the sugars in the dough into carbon dioxide gas and ethanol (a type of alcohol). The carbon dioxide gas gets trapped in the dough, making it puff up!

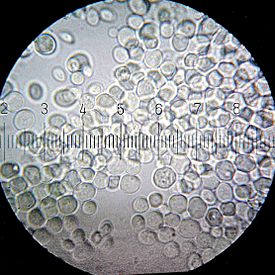

Baker's yeast belongs to a species called Saccharomyces cerevisiae. This is the same species used to make alcoholic drinks, where it's called brewer's yeast. But don't worry, they are different types, or "strains," of the same species. Baker's yeast is a tiny, single-cell living thing that can even be found on and around the human body.

For yeast to grow well, it needs food like sugar. You can also use water from boiled potatoes, or even the potatoes themselves, in bread dough to help the yeast. However, too much sugar can make the yeast dry out. Both salt and sugar can slow down yeast growth, but salt has a stronger effect. Some people think fats, like butter or eggs, slow yeast down, but others say small amounts of fat can actually help bread get bigger.

Another type of wild yeast, Saccharomyces exiguus, is sometimes used in baking. It's often found on plants, grains, and fruits. This yeast is usually part of a sourdough starter, which is a mix of flour and water that has natural yeasts and bacteria growing in it.

Contents

The Story of Baker's Yeast

No one knows exactly when yeast was first used for baking. The oldest clear records come from Ancient Egypt. Scientists think that someone might have left a mix of flour and water out for longer than usual on a warm day. The natural yeasts in the flour then caused the mix to ferment, or bubble up, before it was baked. The bread that came out would have been much lighter and tastier than the flat, hard breads they made before.

It's believed that the first ways of making bread rise were similar to how sourdough is made today. People probably discovered that yeast made flatbread dough rise. They would then either grow the yeast separately or keep a bit of old dough to mix into new batches. Also, making bread rise seems to have developed around the same time as making beer. The foam from beer making, called barm, could also be used to make bread.

Early bakers didn't understand microbiology (the study of tiny living things) like we do today. But they still managed to keep their favorite yeast cultures alive by reusing doughs and starters. Over time, people learned how to separate and grow specific types of yeast, just like they did for beer. They would grow yeast in a liquid similar to beer wort, which often included malted barley and wheat flour. These early yeast cultures were the ancestors of modern baker's yeast. Bakers were careful to keep them clean to avoid what we now know as bacterial contamination. They even used things like hops (used in beer) and boiled the growth liquid to keep the yeast healthy.

In the 1800s, bread bakers often got their yeast from beer brewers. This led to sweeter breads. But then, beer brewers started using a different type of yeast (Saccharomyces pastorianus) that didn't float to the top as much, causing a shortage of yeast for bread. So, in 1846, the Vienna Process was created. This process helped bakers grow and collect top-fermenting yeasts, which were called "press-yeast."

After Louis Pasteur's important work in microbiology, people learned even better ways to grow pure types of yeast. In 1879, Great Britain started using special tanks to grow S. cerevisiae. In the United States, around the early 1900s, machines called centrifuges were used to collect and concentrate the yeast. This made modern commercial yeast possible and turned yeast production into a big industry. The liquid yeast made by small bakers became "cream yeast," and then "compressed yeast," which was a fresh, solid block of yeast. This compressed yeast became the main type of yeast for bakers in many Western countries in the early 20th century.

During World War II, a company called Fleischmann's created a granulated active dry yeast for the US military. This yeast didn't need to be kept cold, lasted longer, and worked well in different temperatures. It's still the standard yeast for US military recipes today. Fleischmann's also made yeast that would make dough rise twice as fast, cutting down on baking time. Later, in 1973, Lesaffre created instant yeast, which is now very popular and used a lot instead of fresh and dry yeast.

Modern baker's yeast is still Saccharomyces cerevisiae. One cool thing about it is that it's not stopped by propionates. These are often added to baked goods like bread to stop mold and bacteria from growing. However, sorbates do stop yeast from working, so they aren't added directly to dough with yeast. Instead, they might be sprayed on finished products or put into packaging.

Different Kinds of Baker's Yeast

| Nutritional value per 100 g (3.5 oz) | |

|---|---|

| Energy | 1,361 kJ (325 kcal) |

|

41.22 g

|

|

| Sugars | 0 g |

| Dietary fiber | 26.9 g |

|

7.61 g

|

|

|

Protein

|

40.44 g

|

| Vitamins | Quantity

%DV†

|

| Thiamine (B1) |

956%

10.99 mg |

| Riboflavin (B2) |

333%

4 mg |

| Niacin (B3) |

251%

40.2 mg |

| Pantothenic acid (B5) |

270%

13.5 mg |

| Vitamin B6 |

115%

1.5 mg |

| Folate (B9) |

585%

2340 μg |

| Choline |

7%

32 mg |

| Vitamin C |

0%

0.3 mg |

| Minerals | Quantity

%DV†

|

| Calcium |

3%

30 mg |

| Iron |

17%

2.17 mg |

| Magnesium |

15%

54 mg |

| Manganese |

15%

0.312 mg |

| Phosphorus |

91%

637 mg |

| Potassium |

32%

955 mg |

| Sodium |

3%

51 mg |

| Zinc |

84%

7.94 mg |

| Other constituents | Quantity |

| Water | 5.08 g |

|

Link to USDA Database entry

|

|

| †Percentages estimated using US recommendations for adults. | |

Baker's yeast comes in several forms, mainly differing in how much water they contain. Each type has its own benefits, and the choice often depends on the recipe and the baker's experience. Dry yeast types are great for storing for a long time, often over a year at room temperature, without losing their power. Generally, with a few small adjustments for liquid and temperature, you can swap different types of commercial yeast for each other.

- Cream yeast is like the liquid yeast used in the 1800s. It's a liquid mix of yeast cells taken from their growing liquid. It's mostly used in big industrial bakeries that have special machines for mixing large amounts. You usually won't find this in regular stores.

- Compressed yeast is cream yeast with most of the water taken out. It's a soft, beige solid. You might know it as small, foil-wrapped cubes called cake yeast in stores. It also comes in bigger blocks for commercial use. This type goes bad quickly, so it's less common in supermarkets now. Active dry and instant yeast have become more popular because they last longer. However, compressed yeast is still widely used by professional bakers and can handle cooler temperatures better than other types.

- Active dry yeast is the most common type for home bakers in the United States. It looks like coarse, oblong granules. These granules have live yeast cells inside a thick layer of dry, dead cells and some growth liquid. Most of the time, you need to "proof" or rehydrate active dry yeast first by dissolving it in warm water. It can be stored at room temperature for a year or frozen for over ten years. This means it lasts longer than other types, but it can be sensitive to sudden temperature changes when you use it.

- Instant yeast looks similar to active dry yeast but has smaller granules and many more live cells in the same amount. It doesn't last as long as active dry yeast, but you usually don't need to rehydrate it. You can often add it directly to your dry ingredients, unless the dough is very dry. Instant yeast usually has a little ascorbic acid (Vitamin C) added to help it last. Some companies make special instant yeasts for doughs with a lot of sugar. These are called osmotolerant yeasts because they can handle high sugar levels.

- Rapid-rise yeast is a type of dried yeast, usually a form of instant yeast, with very small granules. This helps it dissolve faster in dough and produce more carbon dioxide, making the dough rise quicker. Some baking experts think it might make the finished bread less flavorful, but others, like Cook's Illustrated magazine, say it doesn't make much difference for simple recipes. Rapid-rise yeast is often sold for use in bread machines.

- Deactivated yeast is yeast that is no longer alive and cannot make dough rise. It's not used like other yeast types. It's typically used in small amounts (about 0.1% of the flour weight) for pizza and pan bread doughs. It helps make the dough more stretchy and easier to work with.

Instant vs. Active Dry Yeast

Instant and active dry yeast are basically the same ingredient, but they come in slightly different forms and are used a bit differently. You should keep sealed packets of both types at room temperature. Once opened, store them in an airtight container in the refrigerator. Here are the main differences:

- Active yeast needs water first: Instant yeast can be mixed right into your dry ingredients. Active dry yeast, however, must first be dissolved and rehydrated in warm water before you add it to your recipe.

- Instant yeast rises faster: Because instant yeast has a finer texture, you can often skip the first rising time and shape your loaves right after kneading. Doughs made with active dry yeast usually need longer rising times for the yeast to work its way through the dough.

Popular Yeast Brands

For big bakeries, yeast is sold in large packages (like blocks for fresh yeast or vacuum-packed bags for dry or instant). But for home use, yeast often comes in small, pre-measured packets. For active dry and instant yeast, a single packet (enough for an average bread recipe using 500g to 1000g of dough) is usually about 2.5 tsp (around 12 mL) or about 7 grams. You use less yeast if you're making a "pre-ferment" (a starter dough). Generally, you won't taste the yeast in baked bread if the amount of added yeast is less than 2.5% of the flour weight.

Some well-known commercial brands of baker's yeast include Lesaffre's SAF red and SAF gold, Fleischmann's, and Red Star Yeast.

Yeast in Science

Model Organism

Because baker's yeast is easy to get and grow, it has been used for a long time in science for chemical, biological, and genetic research. It's called a model organism because scientists can study it to learn about more complex living things, including humans. Saccharomyces cerevisiae can live with or without oxygen. When oxygen and sugars are present, it performs aerobic fermentation. In 1996, after six years of work, S. cerevisiae became the first eukaryote (a living thing with cells that have a nucleus) to have its entire genome (all of its genetic information) sequenced. It has over 12 million base pairs and about 6,000 genes. Since then, it has continued to be very important in genetic research. For example, much of what we know about the cell division cycle (how cells divide and grow) was discovered by studying yeast.

Industrial Production

The baking industry relies on companies that specialize in making yeast in large amounts. Since the late 1800s, baker's yeast has been produced by these special companies.

The main ingredients for making yeast in factories are yeast cultures and sugar from cane and sugar beet. But they also need various minerals, nitrogen, and vitamins.

The process of making yeast involves several steps, which can vary by manufacturer:

- First, pure yeast cultures are grown in a lab for 2 to 4 days. Then, they are grown in bigger batches for 13 to 24 hours without air.

- Next, there are intermediate and stock fermentation stages where the yeast is fed gradually and given a constant supply of air.

- Finally, there's a main fermentation stage with lots of air for up to 15 hours.

- After that, the yeast is filtered, mixed, shaped, cut, and dried.

The yeast grows from hundreds of kilograms in the middle stages to tens of thousands of kilograms in the final stage, where most of the yeast is produced. In the earlier stages, more ethanol and other alcohols are made. But in the final stages, ethanol production is greatly reduced (up to 95%) by controlling the amount of oxygen and sugar. This helps to increase the amount of yeast produced instead.

The yeast industry is very concentrated, meaning a few big companies control most of the market. In 2006, five companies held about 80% of the worldwide market for dry yeast. Dry yeast is often shipped long distances and sold in developing countries. However, big industrial customers often prefer to get fresh yeast from local factories. For example, in 2006, one company had about 90% of the liquid yeast market in the UK. In the USA, companies like Lesaffre Group, AB Vista, GB Plange, and AB Mauri produced hundreds of thousands of metric tons of yeast in 2012.

Images for kids

See also

In Spanish: Levadura de panadería para niños

In Spanish: Levadura de panadería para niños