Fibre-reinforced plastic facts for kids

Fibre-reinforced plastic (FRP), also known as fibre-reinforced polymer, is a cool composite material. Think of it as a super-strong mix! It's made from a polymer (which is a type of plastic) that's made even stronger with tiny threads called fibres. These fibres are usually glass (like in fibreglass), carbon (like in carbon-fibre-reinforced polymer), or aramid (a tough synthetic fibre). Sometimes, other fibres like wood or boron are used too. The plastic part is often a type of epoxy or polyester plastic.

FRPs are used in many places, from aerospace (like planes) and cars to boats and buildings. You can also find them in things like ballistic armour and special air tanks for divers.

Contents

How Fibre-Reinforced Plastics Began

The very first fibre-reinforced plastic was called Bakelite. A smart inventor named Leo Baekeland created it. He was trying to find a replacement for shellac, a natural resin. Baekeland studied how different chemicals reacted. In 1905, he discovered how to make a hard, mouldable material by controlling heat and pressure on certain chemicals. This was the world's first synthetic plastic! He shared his amazing invention in 1909.

Scientists kept working on fibre-reinforced plastics in the 1930s. The aviation industry, which builds planes, was especially interested in these new strong materials.

The Discovery of Glass Fibres

A big step happened in 1932 when a researcher named Games Slayter accidentally made glass fibres. He was working at a company called Owens-Illinois. He aimed a jet of air at melted glass and, surprise, it made fibres! A patent for making glass wool was applied for in 1933.

Owens later joined with the Corning company. In 1936, they started making their special "fibreglas" (with one 's'). At first, this fibreglas was used for insulation because it trapped a lot of air.

Combining Fibres with Plastic

A suitable plastic resin to mix with "fibreglas" was developed in 1936 by du Pont. This allowed the air in the fibreglas to be replaced by plastic. This new material wasn't as good for insulation, but it was super strong! For the first time, this mix of glass fibres and plastic showed great promise as a building material. Many glass fibre composites are still called "fibreglass" today.

In 1937, Ray Greene made the first boat from this new composite material. However, the plastic was a bit brittle back then. By 1939, Russia had reportedly built a plastic passenger boat, and the US had made parts of an aircraft from plastic. The first car with a fibreglass body was the 1946 Stout Scarab, though only one was ever built.

The Fairchild F-46 plane, which first flew in 1937, was one of the first to use fibre-reinforced plastic. Later, in the 1940s, more experiments led to planes like the XBT-19, which had a fibreglass fuselage.

Newer Fibres Emerge

Carbon fibre started being made in the late 1950s and became more common in the 1960s. Around the same time, aramid fibres (like Kevlar) were also developed by DuPont. Today, these fibres are used widely when plastics need to be extra strong or flexible. Glass fibres are still the most common, but carbon-fibre and carbon-fibre-aramid mixes are popular in planes, cars, and sports gear. These three – glass, carbon, and aramid – are the main types of fibres used in FRPs.

The production of plastics really grew in the mid-20th century. Lower costs and new ways to make things made plastics very popular. By the late 1970s, more polymers (plastics) were made than steel! Fibre-reinforced plastics have been a key part of this growth from the start.

What is Fibre-Reinforced Plastic?

A polymer is a large molecule made of many smaller units linked together. When one or more polymers are mixed with other things to improve their properties, the result is called a plastic. Composite plastics are made by joining two or more different materials to create a final product with special features. Fibre-reinforced plastics are a type of composite plastic that uses fibres to make plastics much stronger and more flexible.

The original plastic material, before fibres are added, is called the matrix or binding agent. This matrix plastic is tough but not super strong on its own. The fibres are much stronger and stiffer, and they reinforce the matrix. How much the strength and flexibility are improved depends on the fibres and the plastic, how much of each is used, and how long and in what direction the fibres are placed in the plastic. When a material is called FRP, it means it's stronger or more flexible than the plastic matrix alone.

How Fibre-Reinforced Plastics are Made

Making FRP involves two main steps: first, making the fibre material, and second, joining these fibres with the plastic matrix during a process called moulding.

Making the Fibres

Fibres can be made in two main ways:

- Two-dimensional fibres are arranged flat, like a woven cloth. They are strong in two directions (length and width) but not through their thickness. This can make them harder to work with and more expensive to produce.

- Three-dimensional fibres have threads going in all directions, including through the thickness of the material. This makes them stronger, especially against impacts, and can help reduce manufacturing costs.

How Fibre Preforms are Made

Fibre preforms are the shapes the fibres take before they are mixed with the plastic. They often come in sheets, continuous mats, or long strands for spraying. The four main ways to make these fibre preforms are by weaving, knitting, braiding, and stitching.

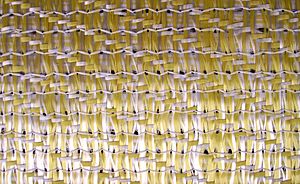

- Weaving can make flat, two-dimensional fabrics. It can also create multi-layer fabrics with fibres in three dimensions, but this can be complex to set up.

- Braiding is good for making narrow, flat, or tube-shaped fabrics. It can create fabrics where fibres are at different angles, like 45 degrees, which is different from standard weaving.

- Knitting uses needles to create fabrics. Modern knitting machines can make multi-layer fabrics and even form them into specific three-dimensional shapes, reducing waste.

- Stitching is a simpler method. It involves using a needle to sew layers of fabric together, creating a 3D structure. This method is flexible because it uses standard two-dimensional fabrics.

Shaping the Plastic Parts

A rigid structure, often called a "mould" or "tool," is used to give FRP parts their shape. Moulds can be open (like a bowl) or completely enclose the part.

The moulding process starts by putting the fibre preform into the mould. The fibres can be dry, or they can already have some resin mixed in (called "prepreg"). If the fibres are dry, the resin is added by hand or injected into the mould. Then, the part is "cured," which means the resin hardens, making the fibres and plastic take the shape of the mould. Sometimes, heat or pressure is used to help the resin cure better and make a higher quality part.

Here are some ways FRP parts are shaped:

Bladder Moulding

Individual sheets of prepreg (fibres with resin) are placed in a mould with a balloon-like bladder. The mould is closed and heated. The bladder is then filled with air, pushing the material against the mould walls to form the shape.

Compression Moulding

In this method, a block or sheet of plastic material, often with reinforcing fibres already mixed in, is placed into a mould. The mould is closed, and the material is shaped and hardened using pressure and heat. This method is great for making detailed and complex shapes quickly, usually within 20 minutes.

Autoclave and Vacuum Bagging

Sheets of prepreg are placed in an open mould and covered with special films and a vacuum bag. Air is sucked out of the bag, and the whole mould is put into an autoclave (a heated pressure vessel). The part cures slowly under continuous vacuum, which removes any trapped gases. This process is common in the aerospace industry because it allows very precise control, ensuring strong and safe parts for planes. However, it's slow and takes a lot of work, so it's often more expensive.

Mandrel Wrapping

Sheets of prepreg are wrapped around a metal rod called a mandrel. The material is then squeezed tight with tape. The parts are usually heated in an oven. After curing, the tape and mandrel are removed, leaving a hollow tube, often made of carbon. This creates strong, hollow carbon tubes.

Wet Layup

In wet layup, layers of reinforcing fibres are placed in an open mould. Then, a liquid resin is poured over the fabric and worked into it. The mould is left for the resin to harden, usually at room temperature. Sometimes, a vacuum bag is used to press the material. This method is often used with glass fibres to make things like skis, canoes, and surfboards.

Chopper Gun

Long strands of fibreglass are fed into a special hand-held gun. This gun chops the fibres into small pieces and mixes them with a liquid resin. The mixture is then sprayed onto the mould surface. This is good for making many large parts at a low cost, but the parts might not be as strong or precise as those made with other methods.

Filament Winding

Machines pull bundles of fibres through a bath of wet resin. These resin-soaked fibres are then wound around a spinning metal rod (mandrel) in specific patterns. The parts are cured, and the mandrel is removed, leaving a strong, shaped product.

Pultrusion

Fibre bundles and fabrics are pulled through a bath of wet resin and then shaped into a rough form. The saturated material is then pulled through a heated die, which cures it as it moves. This process makes long, continuous shapes like I-beams, angles, and flat sheets, which are used for things like ladders and platforms.

Resin Transfer Moulding

Also called resin infusion. Fabrics are placed inside a closed mould. Then, wet resin is injected into the mould. Sometimes, the resin is pushed in under pressure, or a vacuum is used to pull the resin into the mould. This method allows for very precise shapes, but sometimes the fabric might not get fully soaked with resin, leading to weak spots.

Good Things and Challenges of FRP

FRP lets designers place the fibres in specific directions to make the plastic stronger where it's needed most. For example, if a part needs to resist a pulling force, the fibres can be lined up parallel to that force. This makes the part super strong in that direction. However, if the force comes from a different direction (perpendicular to the fibres), the part might be weaker. This can be both a good thing (you can design weak spots for hinges) or a challenge (if fibres aren't lined up correctly, the part could fail). When fibres are woven in two or three dimensions, it helps avoid these weak spots because there's always some fibre aligned to resist forces from different directions.

How FRP Can Fail

FRP materials can break if:

- The plastic matrix stretches more than the fibres, causing them to separate.

- Forces pull the fibres away from the plastic matrix.

- The forces are too strong for the fibres themselves, causing the fibres to break.

What Materials are Needed for FRP?

The plastic material (matrix) and the fibres need to meet certain requirements to work well together in FRPs. The plastic must be able to soak into the fibres and ideally bond with them. It also needs to completely cover the fibres to protect them and transfer forces to them. The fibres must be kept separate so that if one part fails, the damage doesn't spread easily. Also, the plastic should stay stable during and after the making process.

The fibres themselves must make the plastic stronger and stiffer. They need to be strong and stiff enough, and they must bond well with the plastic.

Glass Fibre

"Fibreglass reinforced plastics" (FRPs) often use special glass fibres. These are different from the glass fibres used for insulation. Textile glass fibres are made from mixtures of powders like sand (SiO2). These mixtures are heated to very high temperatures (around 1300 degrees Celsius). Then, the melted glass is pushed through tiny holes to make thin filaments, usually 9 to 17 micrometres wide. These filaments are then wound into larger threads and put on spools for use. Glass fibre is the most common fibre for reinforcing plastic.

Carbon Fibre

Carbon fibres are made by heating other fibres, like polyacrylonitrile (PAN), to very high temperatures in a special process called carbonization. This process makes them into pure carbon. By further heating or stretching, their strength or flexibility can be increased. Carbon fibres are also very thin, usually 4 to 17 micrometres wide. These fibres are then wound into larger threads and can be woven or braided into fabrics for use in FRPs.

Aramid Fibre

Aramid fibres are well-known by brand names like Kevlar, Nomex, and Technora. They are made from a type of plastic called an aromatic polyamide. This plastic is spun from a liquid into a strong, crystallized fibre. These fibres are then spun into larger threads to make strong ropes or woven fabrics. Aramid fibres come in different strengths and stiffnesses, so they can be chosen for specific design needs.

Examples of FRP Combinations

| Reinforcing material | Common plastic materials | What gets better |

|---|---|---|

| Glass fibres | UP, EP, PA, PC, POM, PP, PBT, VE | Strength, flexibility, heat resistance |

| Wood fibres | PE, PP, ABS, HDPE, PLA | Bending strength, stiffness, pulling strength |

| Carbon and aramid fibres | EP, UP, VE, PA | Flexibility, pulling strength, squeezing strength, electrical strength. |

| Inorganic particles | Semicrystalline plastics, UP | Even shrinkage, resistance to wear, squeezing strength |

| Microspheres | Glass microspheres | Lighter weight compared to solid fillers |

Where FRPs are Used

Fibre-reinforced plastics are perfect for designs that need to be light, very precise, and have parts that are simpler to make and use. A moulded plastic product is often cheaper, faster, and easier to make than a metal one, and it can be just as strong, or even stronger.

Carbon-Fibre-Reinforced Polymers in Planes

The rudder of an Airbus A310 plane is a great example.

- It's 25% lighter than a traditional rudder made from aluminium.

- It uses 95% fewer parts because many pieces can be combined into simpler moulded shapes.

- This saves money in making the plane and also saves fuel when the plane is flying.

Glass-Fibre-Reinforced Polymers in Cars

Engine intake manifolds (parts that help air get into the engine) are made from glass-fibre-reinforced PA 66 plastic.

- They can be up to 60% lighter than aluminium ones.

- They have a smoother surface and better airflow.

- Fewer parts are needed because complex shapes can be moulded as one piece.

Car gas and clutch pedals are also made from glass-fibre-reinforced PA 66.

- The pedals and their moving parts can be moulded as single units, making them simpler to produce and operate.

- The fibres can be placed to make the pedals stronger against specific forces, making them more durable and safer.

Aluminium windows and doors use plastic parts made of glass fibre reinforced polyamide for insulation. This helps keep buildings warm or cool.

FRP in Buildings and Bridges

FRP can be used to make the beams, columns, and slabs in buildings and bridges stronger. It can even help repair and strengthen parts that have been damaged. For example, if a concrete beam is damaged, it can be repaired and then wrapped with fibre sheets soaked in resin.

For beams, FRP sheets can be added to the bottom to increase their bending strength. The fibres are lined up with the beam's length. For shear strengthening (resisting forces that try to slice the beam), FRP is applied to the sides of the beam, with fibres going across the beam's length. This works like internal steel bars. FRP can be applied in different ways, like just on the sides, in a 'U' shape, or wrapped completely around the beam for maximum strength.

Slabs can be strengthened by adding FRP strips to their bottom. Columns are usually wrapped with FRP all around. This makes them stronger against both shear forces and squeezing forces. The FRP wrap helps hold the column together, making it much tougher.

FRP in Elevators

In 2013, KONE, an elevator company, introduced "Ultrarope." This is a special rope made of carbon fibres sealed in a high-friction plastic. It's designed to replace steel cables in very tall buildings, allowing elevators to go up to 1,000 meters, much higher than steel cables allow (500 meters). The company estimated that in a 500-meter building, an elevator using Ultrarope would use 15% less electricity!

Thinking About FRP Design

FRP is used when regular plastics or other materials aren't strong or flexible enough, or are too expensive. The main idea when designing with FRP is to use it smartly, taking advantage of its special features. The way fibres are placed is very important. If fibres are all in one direction, the material will be weaker in the direction perpendicular to them. So, designers place fibres parallel to the forces a part will experience to make it strong. If a part needs to be flexible, like a hinge, fibres might be placed perpendicular to the forces.

Using fibres in two or three dimensions helps avoid weak spots. Also, making parts with the right thickness and designing complex shapes that can be moulded as a single piece can make the product even stronger by reducing the need for joints or extra parts.

Disposing of and Recycling FRP

Like all plastics, FRPs face challenges when it comes to disposal and recycling. Plastics are hard to recycle because their basic components often can't be easily separated and reused. Many plastics can't be recycled at all. Fibre-reinforced plastics are even harder to recycle because it's tough to separate the fibres from the plastic matrix.

Scientists are looking for ways to safely dispose of FRPs. One way is to burn off the plastic part, which can even create some energy, and then filter out the non-burning fibres. Another way is to burn the non-burning material in a cement kiln, where the fibres become part of the new cement. Even with these challenges, plastics often save energy and money compared to other materials. And with new, more eco-friendly plastics being developed, FRPs will become even better for the environment in the future.

See also

In Spanish: Plásticos reforzados con fibras para niños

In Spanish: Plásticos reforzados con fibras para niños

- Long-fibre-reinforced thermoplastic

- Pre-preg

- Composite material

| Audre Lorde |

| John Berry Meachum |

| Ferdinand Lee Barnett |