Multistage rocket facts for kids

A multistage rocket (also called a step rocket) is a special type of rocket that uses two or more sections, called stages. Each stage has its own engines and fuel. Think of it like stacking several smaller rockets on top of each other, or attaching them side-by-side. Most rockets that go into space have at least two stages, but some have had as many as five!

The main idea behind a multistage rocket is to get rid of weight as the rocket travels higher. When a stage runs out of fuel, it's dropped off. This makes the rocket lighter, so the next stage doesn't have to push as much weight. This "staging" helps the rocket go faster and higher, reaching incredible speeds needed to get into Earth orbit.

In most designs, the first stage is at the bottom and is usually the biggest. The second stage and other upper stages are on top, getting smaller as you go up. Sometimes, extra rockets called solid rocket boosters or liquid boosters are attached to the sides of the first stage. These are sometimes called "stage 0."

Here's how it generally works:

- The first stage and any boosters fire together to lift the whole rocket off the ground.

- When the boosters run out of fuel, they separate and fall away.

- Then, the first stage finishes burning its fuel, separates, and falls away too.

- Now, a smaller, lighter rocket is left. The second stage fires its engines, pushing the rocket even faster.

- This process repeats with each stage until the rocket reaches the speed and height needed for its mission, like putting a satellite into orbit.

It's very hard for a single rocket to reach orbital speed because of how much fuel it would need to carry. Multistage rockets solve this problem by dropping off empty parts, making the journey much more efficient.

Contents

- Why Multistage Rockets Are Needed

- Choosing Rocket Parts

- Hot-Staging: Firing Early

- Tandem vs. Parallel Staging

- Upper Stages: Reaching Orbit and Beyond

- Assembling a Rocket

- Space Debris from Spent Stages

- History of Multistage Rockets

- Separation Events

- Two-Stage-to-Orbit (TSTO)

- Three-Stage-to-Orbit

- Four-Stage-to-Orbit

- Rockets Beyond Earth

- See also

- Images for kids

Why Multistage Rockets Are Needed

Rockets need to reach very high speeds to get into space. The laws of physics limit how fast a single rocket can go based on how much fuel it carries compared to its total weight. To reach speeds like those needed for low Earth orbit, a rocket would need an impossible amount of fuel if it were just one piece.

Multistage rockets get around this limit by breaking the journey into smaller steps. As each lower stage finishes its job and drops off, the remaining rocket is already moving very fast. The next stage then fires, pushing a much lighter rocket even faster. This is like a relay race, where each runner passes the baton to a faster, lighter runner.

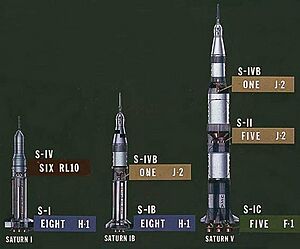

Another cool thing about multistage rockets is that each stage can have different engines. The engines on the first stage are designed to work best when there's a lot of air pressure close to the ground. But the engines on the upper stages are built to work in the near-vacuum of space, where there's almost no air. This makes each part of the rocket super efficient for its specific job.

Building a multistage rocket is more complicated than building a single-stage one. Each time a stage separates, there's a small chance something could go wrong. But the benefits of saving weight and being more efficient are so huge that almost every rocket that has ever put something into orbit has used multiple stages.

Rocket engineers also look at how efficient an engine is, which is called its "specific impulse." A higher specific impulse means the engine uses its fuel more efficiently and can burn for longer. Usually, the first stages of a rocket have lower specific impulse but produce a lot of thrust to quickly push the rocket off the ground. Later stages, higher up where there's less air, can use engines with higher specific impulse because they don't need as much raw power, just efficiency.

Engineers also consider the "thrust-to-weight ratio," which tells them how much pushing power an engine has compared to its weight. For a rocket to lift off, this ratio needs to be greater than 1. The typical ratio for a launch vehicle is between 1.3 and 2.0.

Choosing Rocket Parts

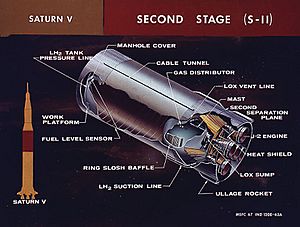

When designing a rocket, engineers need to figure out how much fuel is needed for each stage. They use special calculations based on how much push (total impulse) the rocket needs and how efficient the engine is. Once they know the fuel mass, they can calculate the size of the fuel tanks.

Besides fuel, they also need to think about the weight of the rocket's structure itself, including the engines, electronics, and other equipment. For solid rocket motors, about 91% to 94% of their total weight is fuel. There's also a small amount of "leftover" fuel that can't be used, which is usually around five percent.

For rockets that use liquid fuel, it's a bit more complex because they need two separate tanks: one for the fuel and one for the "oxidizer" (a chemical that helps the fuel burn). The ratio of these two is called the "mixture ratio." This ratio affects not only the size of the tanks but also how efficient the rocket engine is. Engineers balance different needs, like making the tanks the same size for easier building, or making them smaller if space is limited, even if it means a little less efficiency.

Hot-Staging: Firing Early

Hot-staging is a special way rockets separate. Instead of waiting for the first stage to completely shut down and separate before the next stage fires, the next stage starts its engines before the separation. The first stage might even slow down its engines just before this happens.

This method can make the separation process simpler. It also gives the rocket a small boost in how much payload it can carry. Plus, it helps keep the fuel settled at the bottom of the tanks in the upper stage, which is important for the engines to work correctly.

Hot-staging has been used on Russian rockets like the Soyuz and Proton-M. The American Titan rockets also used hot-staging starting with the Titan II. More recently, SpaceX changed their huge Starship rocket to use hot-staging after its first test flight. This made Starship the biggest rocket ever to use this method, and the first reusable one.

Tandem vs. Parallel Staging

There are two main ways multistage rockets are designed:

- Tandem Staging: This is when stages are stacked one on top of the other and fire one after another. The first stage burns, separates, then the second stage burns, and so on. Most rockets use this method.

- Parallel Staging: This is when two or more stages fire at the same time. A great example is the Space Shuttle. It had two Solid Rocket Boosters (SRBs) attached to its main fuel tank. At launch, the SRBs and the main engines fired together. After a few minutes, the SRBs separated and fell away, while the main engines continued to burn fuel from the external tank.

Even though parallel staging involves multiple parts firing at once, engineers still think of it in "stages." For example, the moment the side boosters separate from the main rocket can be considered the end of "stage 0" or the first stage.

Upper Stages: Reaching Orbit and Beyond

The upper stages of a rocket are designed to work high up in the atmosphere or in the vacuum of space. Because there's little or no air pressure, their engines can be designed differently to be super efficient in that environment.

Some upper stages use special propellants that ignite on contact, which means they don't need complex pumps to move the fuel. Others use very cold liquid hydrogen fuel with advanced engines. These upper stages are usually responsible for pushing the payload into its final orbit, or even sending it to higher orbits like GTO (where satellites stay above the same spot on Earth) or even to escape velocity to leave Earth's gravity entirely. Sometimes, upper stages used to move payloads from low Earth orbit to higher orbits are called space tugs.

Assembling a Rocket

Each stage of a rocket is usually built at its own factory and then shipped to the launch site. The process of putting all the rocket stages and the spacecraft payload together is called vehicle assembly.

Smaller rockets can often be put together right on the launch pad using a crane. But for very large rockets, this isn't practical. They are assembled away from the launch pad and then moved into place.

For example, NASA's Apollo Saturn V Moon rocket and the Space Shuttle were built upright in a huge building called the Vehicle Assembly Building. Then, a special crawler-transporter slowly moved the entire rocket stack to the launch pad in an upright position. In contrast, rockets like the Russian Soyuz and SpaceX Falcon 9 are assembled horizontally in a hangar, transported flat, and then lifted upright at the launch pad.

Space Debris from Spent Stages

Unfortunately, spent upper stages of rockets are a big source of space debris. These old rocket parts can stay in orbit for many years after they've been used, just floating around. Sometimes, a single upper stage can even break apart, creating many smaller pieces of debris.

Since the 1990s, rocket engineers have tried to "passivate" spent upper stages. This means they remove any leftover energy sources on the rocket, like dumping unused fuel or discharging batteries. This helps prevent the stage from exploding or breaking apart later, which would create more space junk.

Many early rockets, both from the Soviet and U.S. space programs, were not passivated. When scientists started studying the problem of space debris, they realized that a lot of it came from these old, unpassivated rocket stages breaking up.

History of Multistage Rockets

The idea of multistage rockets isn't new!

- The oldest known multistage rocket was described in a 14th-century Chinese book called Huolongjing. It was called the "fire-dragon issuing from the water" and was used by the Chinese navy. It was a two-stage rocket: booster rockets would burn out, and before they did, they would automatically light smaller rocket arrows that shot out of the dragon-shaped front of the missile.

- In Korea, an early multistage rocket called the Juhwa was developed in the 14th century. It was small, about 15 cm long, and could fly around 200 meters. Korea continued to develop this technology, leading to the Singijeon rockets in the 16th century.

- In Europe, the first experiments with multistage rockets were done in 1551 by Austrian Conrad Haas.

- Later, the idea was developed independently by several other scientists, including Kazimieras Simonavičius (Polish-Lithuanian), Konstantin Tsiolkovsky (Russian), Robert Goddard (American), Hermann Oberth (German), and Louis Damblanc (French).

The first modern, high-speed multistage rockets were the RTV-G-4 Bumper rockets, tested in the U.S. from 1948 to 1950. These combined a V-2 rocket with a smaller WAC Corporal rocket. One of these rockets reached an amazing height of 393 kilometers (about 244 miles) in 1949.

In the 1940s and 50s, Soviet engineers like Mikhail Tikhonravov and Dmitry Okhotsimsky also worked on theories for parallel staging, where multiple stages fire at once. Their work led to the design of the famous R-7 Semyorka rocket. The American Atlas I and Atlas II rockets also used a similar parallel staging idea, where outer booster engines would drop away, leaving a central engine to finish the first stage's burn.

Separation Events

Every time a part of a multistage rocket separates, it adds a bit of risk to the mission. Less separation means less complexity and fewer chances for something to go wrong.

Separations happen when:

- Stages or side boosters detach after their fuel is used up.

- The payload fairing (the nose cone protecting the satellite) separates before the rocket reaches orbit.

- A launch escape system (used to pull astronauts to safety in an emergency) separates after the early part of the launch.

These separations are usually done using small explosive bolts or pneumatic (air-powered) systems.

Two-Stage-to-Orbit (TSTO)

A two-stage-to-orbit (TSTO) rocket uses two main stages to reach orbital speed. This is a very common design for rockets today. It's simpler than a three-stage rocket but more complex than a single-stage-to-orbit rocket (which hasn't been successfully built yet).

Three-Stage-to-Orbit

A three-stage-to-orbit rocket uses three distinct stages to reach Earth orbit. This is also a very common design.

Examples of Three-Stage Rockets

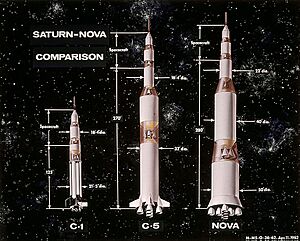

- Saturn V (the rocket that took astronauts to the Moon!)

- Vanguard

- Ariane 4 (sometimes with extra boosters)

- Proton (can have an optional fourth stage)

- Long March 1

- Zenit-3SL

- KSLV-2 "Nuri"

Examples of Two Stages with Boosters

Many modern rockets use two main core stages but add extra side boosters (sometimes called "stage-0"). These boosters and the first core stage fire at the same time to give a huge initial push. The boosters then separate a few minutes into the flight.

- US Space Shuttle (SRBs and main engines)

- Ariane 5

- Atlas V

- Delta IV

- Falcon Heavy

- Soyuz

- Space Launch System

Four-Stage-to-Orbit

A four-stage-to-orbit rocket uses four separate stages to reach Earth orbit. These are often used with rockets that use solid fuel.

Examples of Four-Stage Rockets

- Ariane 1

- PSLV

- Minotaur IV

- Proton (when using its optional fourth stage)

- Minotaur V (actually has five stages!)

Rockets Beyond Earth

- NASA-ESA Mars Ascent Vehicle (MAV) (This is a 2-stage rocket planned to launch from Mars in 2028 to bring rock samples back to Earth!)

See also

- Three-stage-to-orbit

- Two-stage-to-orbit

- Single-stage-to-orbit

- Reusable launch system

- Space tug

- Conrad Haas

- Huolongchushui

Images for kids