Sewing machine facts for kids

A sewing machine is a clever machine that helps us join fabric and other materials using thread. These amazing machines were first invented during the Industrial Revolution, a time when many new inventions changed how things were made. Their main goal was to make sewing much faster and easier than doing it all by hand.

Since the first sewing machine design by Thomas Saint in 1790, these machines have made a huge difference. They have greatly improved how quickly and efficiently clothes and other fabric items are made.

There are two main types of sewing machines. Home sewing machines are for one person to sew individual items. They often use one type of stitch at a time. Modern home machines make stitching automatic, so fabric moves smoothly. Older machines used a hand crank or a foot pedal called a treadle. Later, electric machines became popular.

Industrial sewing machines are different. They are bigger, faster, and built for heavy-duty work in factories. They come in many sizes and are designed for specific tasks.

Contents

The Story of Sewing Machines

Early Inventions

The idea for a mechanical sewing device began a long time ago. In 1755, Charles Fredrick Wiesenthal, an engineer from Germany working in England, received a patent for a special needle. This needle had two points and an eye at one end, designed to help with sewing.

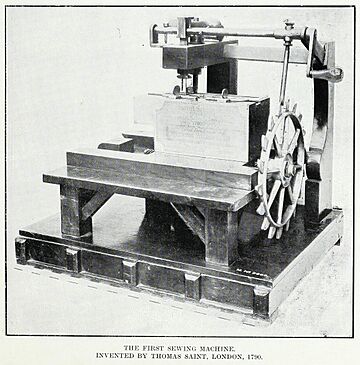

In 1790, English inventor Thomas Saint created the first complete design for a sewing machine. His machine was meant for tough materials like leather and canvas, often used for things like shoe soles. Saint was a skilled cabinet maker. His design included many useful parts, like an arm that hung over the fabric, a way to move the material, and a special hook for the thread. He wanted to reduce the amount of hand-stitching needed for garments.

Saint's machine used a method called the chain stitch. This stitch uses a single thread to make simple loops in the fabric. A sharp tool would make a hole, and a rod would carry the thread through. Then, it would be hooked underneath and moved to the next spot, locking the stitch. This machine was advanced for its time. It helped make items like saddles and bridles, and even ship sails.

Other inventors also worked on sewing machines. In 1804, Thomas Stone and James Henderson in England built a machine. In Scotland, John Duncan created a machine for embroidering. An Austrian tailor, Josef Madersperger, started developing his machine in 1807. He showed his first working model in 1814.

The first practical sewing machine that was widely used came from Barthélemy Thimonnier, a French tailor, in 1829. His machine also used a chain stitch to sew straight lines. In 1830, he received a patent for his invention. He and his partners then opened the world's first factory to make clothes using machines. They made army uniforms for the French Army. However, the factory was unfortunately burned down. Some say workers feared losing their jobs because of the new machines. Thimonnier's first machine was made of wood, but later versions were metal. You can see a model of his early machine at the Science Museum in London.

Growing Competition

In America, Walter Hunt invented the first lockstitch sewing machine in 1832. His machine used a needle with the eye and point at the same end. It also had a shuttle that carried a second thread. The needle would go through the fabric, making a loop. The shuttle would then pass through this loop, locking the threads together.

Elias Howe, from Massachusetts, created his own sewing machine in 1845. His machine also used a lockstitch. A key improvement was how the needle moved away from the point, starting from the eye. After trying to get interest in his machine in England, he returned to America. He found that others, including Isaac Merritt Singer, were using ideas similar to his patented design. Howe won a court case in 1854. This meant other manufacturers had to pay him for using his ideas.

Isaac Singer saw a sewing machine being fixed and thought he could design a better one. His machine used a vertical needle and a special foot to hold the cloth. It also had a basic system to control thread tension. Singer received an American patent in 1851. He adapted the foot treadle, which had been used for centuries, to power his sewing machine. This left both hands free for the sewer.

After Howe won his case, Singer paid him for the machines he had already made. Singer then got a license to use Howe's patent. He also partnered with a lawyer, Edward Clark. Together, they created the first "hire-purchase" plan. This allowed people to buy machines by making payments over time, making them more affordable.

Meanwhile, Allen B. Wilson developed a quieter and smoother way to interlock threads using a rotary hook instead of a shuttle. He partnered with Nathaniel Wheeler to create the Wheeler & Wilson Company. This company made more machines in the 1850s and 1860s than any other. Wilson also invented the "four-motion feed mechanism." This system moves the cloth forward, down, back, and up, pulling it through smoothly. This mechanism is still used on almost every sewing machine today!

Many companies were formed in the 1850s, leading to many disagreements over patents. To solve this, in 1856, the Sewing Machine Combination was formed. This group included Singer, Howe, Wheeler, Wilson, and Grover and Baker. They shared their patents, meaning other manufacturers had to pay a fee for each machine they made. This agreement lasted until 1877.

James Edward Allen Gibbs patented the first chain stitch single-thread sewing machine in 1857. He partnered with James Willcox to form the Willcox & Gibbs Sewing Machine Company. Their commercial sewing machines are still used today, over a century later!

-

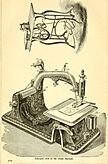

Elias Howe's lockstitch machine, invented in 1845

Spreading Across Homes and Factories

William Jones started making sewing machines in England in 1859. His company, later known as the Jones Sewing Machine Co. Ltd, became a major manufacturer. It was eventually bought by Brother Industries of Japan in 1968.

At first, clothing manufacturers were the main customers for sewing machines. They used them to make the first ready-to-wear clothes and shoes. By the 1860s, people started buying machines for their homes. These machines became very common in middle-class homes. They allowed families to make and mend clothes much faster. For example, a man's shirt that took 14 and a half hours to sew by hand could be made in about one hour with a machine!

In 1877, the world's first crochet machine was invented by Joseph M. Merrow. This machine was the first to make an overlock stitch, which is great for finishing fabric edges. The Merrow Machine Company became a leading maker of overlock sewing machines.

In 1885, Singer patented the Singer Vibrating Shuttle machine. This was a very practical sewing machine for home use. Millions were made, and it was popular until newer rotary shuttle machines came along in the 20th century.

The first electric sewing machines were introduced by Singer Sewing Co. in 1889. At first, these were standard machines with a motor attached to the side. As more homes gained electricity, electric machines became more popular. The motor was then built right inside the machine.

The Rise of Electronic Machines

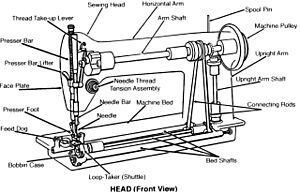

For a long time, sewing machines were purely mechanical. They used gears, shafts, and levers to work. But in the 1970s, electronic machines arrived. These machines included computer chips, circuit boards, and extra motors. These electronic parts allowed for cool new features. Machines could now automatically cut threads, position the needle, and create many different stitch patterns. While electronic machines offer more features, mechanical machines often last longer, sometimes over 100 years!

Types of Stitches

Sewing machines can create many different kinds of stitches, from simple to decorative. There are over three dozen distinct stitch types officially recognized today!

The most common plain stitches fall into four main groups: chainstitch, lockstitch, overlock, and coverstitch.

- Chain Stitch: This stitch was used by early sewing machines. It uses a single thread to form a series of loops. However, it has a big drawback: if the thread breaks, the whole stitch can easily unravel. It's still used in clothing factories, often combined with another stitch for strength.

- Lockstitch: This is the most common stitch you'll find on home sewing machines and many industrial ones. It uses two threads: one from the needle and one from a bobbin. The threads interlace at each needle hole, creating a strong, secure stitch that won't easily unravel.

- Overlock Stitch (Serger Stitch): Also known as "serging," this stitch is made with two to four threads and one or two needles. Overlock machines often have knives that trim the fabric edge just before stitching. This stitch is perfect for stretchy fabrics, finishing raw edges to prevent fraying, and creating neat seams.

- Coverstitch: This stitch uses two or more needles and one or two loopers. It creates parallel rows of stitching on top, while the looper threads cross back and forth underneath. It's called a coverstitch because it covers raw seam edges, much like an overlock stitch. It's often used in clothing to finish hems and create flat seams.

A zigzag stitch is a special kind of lockstitch. Instead of sewing in a straight line, the needle moves back and forth. This stitch is useful for preventing fabric from fraying, sewing stretchy materials, and temporarily joining two pieces of fabric edge-to-edge. A special part called a cam controls the needle's side-to-side motion.

How Fabric Moves: Feed Mechanisms

For a sewing machine to work, the fabric needs to move forward with each stitch. This movement is called "feed." There are several ways machines do this: drop feed, needle feed, walking foot, puller, and manual feed. Sometimes, a machine uses more than one type of feed.

- Drop Feed: This is used by most home machines. Small, serrated "feed dogs" pop up through slots in the machine's surface. They grip the fabric and pull it forward, then drop down and move back to start again. A "presser foot" holds the fabric against the feed dogs.

- Differential Feed: A special type of drop feed with two sets of feed dogs. These can move at different speeds to gently stretch or gather stretchy fabrics as they are sewn. This is very common on overlock machines.

- Needle Feed: Found only in industrial machines, this system moves the fabric while the needle is still in it. The needle itself helps pull the material forward. This is great for precise work.

- Walking Foot: Instead of a stationary presser foot, a walking foot moves along with the fabric. It's very helpful for sewing thick materials, spongy fabrics, or many layers at once, as it helps all layers move evenly.

- Puller Feed: Some factory machines have an extra "puller" that grips the fabric from behind the needles and pulls it through. This is very strong and reliable, especially for large, heavy items like tents.

- Manual Feed: This is used for freehand embroidery or quilting. The sewer controls the fabric's movement and stitch length entirely by hand. The machine's feed dogs are usually lowered for this.

Needles

Sewing machines use special needles. These needles are designed for the machine's specific needs and the type of material being sewn. Modern machines often have a needle guard. This is a safety feature that helps prevent injuries.

Thread Tension

Tension in a sewing machine refers to how tightly the thread is pulled between the needle and the bobbin. Sewing machines have special discs and a regulator to control this. If your stitches look too loose or too tight, it's usually a sign that the tension needs adjusting.

Industrial vs. Home Machines

There are two main types of sewing machines: industrial and domestic (home use).

- Industrial Sewing Machines: These are larger, faster, and built for heavy-duty work in factories. They are designed to do one specific task very well and can run continuously for long periods. They have bigger parts and powerful motors. Industrial machines often have separate motors mounted under the table. These can be "servo motors" (which use less electricity and are quiet when not sewing) or "clutch motors" (which run constantly and are always spinning).

- Domestic Sewing Machines: These are smaller and designed for one person to sew individual items at home. Their motors are built inside the machine. They are versatile and can perform many different stitch types, but they are not meant for continuous, heavy-duty use like industrial machines.

How Sewing Machines Changed the World

Before sewing machines, women spent a huge amount of time making and mending clothes for their families. Even with help, a middle-class housewife might spend several days each month on this task. For example, an experienced seamstress needed about 14 hours to make a man's dress shirt by hand. A woman's dress took about 10 hours. Most people owned only a few outfits.

Sewing machines dramatically cut down this time. A dress shirt could be made in just over an hour, and a dress in about an hour. This meant women had more free time for other activities or to seek jobs outside the home.

The use of sewing machines in factories further changed clothing production. Instead of being made at home, clothes were now made in large factories. This led to a huge increase in how many clothes could be made. Fewer workers could produce the same amount of clothing, which made clothes much cheaper and more available to everyone.

However, these changes also brought challenges for workers. While some middle-class women gained more leisure time, many working-class women in the clothing industry faced very long hours and low wages, especially during busy seasons. This economic pressure meant that some families struggled to make ends meet.

Societal views at the time sometimes suggested that women should not work outside the home. However, for many working-class families, it was a necessity. Many women worked in manufacturing jobs, often from home, making ready-made clothing for low pay. This system allowed the clothing industry to produce many items cheaply. Economic pressures also meant that children sometimes had to work to help their families, even when laws tried to keep them in school.

Despite these difficulties, the sewing machine also created new opportunities. Many women who had previously been busy at home could now find jobs in factories. This increased family income, allowing families to afford more clothes and other goods. For seamstresses, home sewing machines meant they could make clothes for everyday people, boosting their earnings during slower times. While some jobs were lost when industrial machines first became popular, in the long run, the growing clothing industry created thousands of new jobs for men, women, and children.

The impact of the sewing machine wasn't just on clothing. It also boosted other industries. For example, more cotton was needed to supply the new clothing factories, leading to more cotton farming. Metal companies provided parts for the machines, and shipping companies moved the increased amounts of goods. Beyond clothes, sewing machines became important for making furniture upholstery, curtains, towels, toys, books, and many other products we use every day.

See also

In Spanish: Máquina de coser para niños

In Spanish: Máquina de coser para niños

- Sewing

- Embroidery machine

- List of sewing machine brands