W. Edwards Deming facts for kids

Quick facts for kids

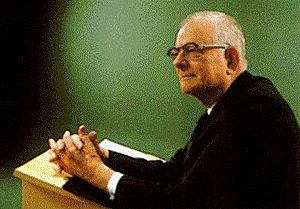

W. Edwards Deming

|

|

|---|---|

|

|

| Born |

William Edwards Deming

October 14, 1900 Sioux City, Iowa, U.S.

|

| Died | December 20, 1993 (aged 93) Washington, D.C., U.S.

|

| Alma mater | |

| Known for | PDCA, total quality management, quality control |

| Spouse(s) |

Agnes Bell

(m. 1922; died 1930)Lola Elizabeth Shupe

(m. 1932; died 1986) |

| Children | 3 |

| Scientific career | |

| Fields |

|

| Influences | Walter A. Shewhart |

William Edwards Deming (born October 14, 1900 – died December 20, 1993) was an American expert in many fields. He was an engineer, a statistician (someone who works with data), a professor, and a consultant for businesses. He helped create ways to collect information using samples, which are still used today by the U.S. government. He is often called the "father of the quality movement" because his ideas greatly helped Japan after World War II. He is best known for his ideas on how to manage companies better.

Contents

Who Was W. Edwards Deming?

Deming earned his first degree in electrical engineering from the University of Wyoming in 1921. He then got advanced degrees in mathematics and physics from the University of Colorado (1925) and Yale University (1928). While studying at Yale, he worked at a company called Western Electric. Later, he worked for the U.S. Department of Agriculture and the Census Department.

After World War II, Deming went to Japan to help with their census. While there, he was asked to teach Japanese business leaders about his ideas on management and how to improve quality. He returned to Japan many times to share his knowledge. He also became a professor at New York University and worked as a consultant in Washington, D.C.

Deming wrote several important books, including Out of the Crisis and The New Economics for Industry, Government, Education. Besides his work, he also loved music. He played the flute and drums and even wrote his own songs.

In 1993, he started the W. Edwards Deming Institute in Washington, D.C. This institute helps people learn about Deming's ideas to make society better.

How Did Deming's Ideas Help Japan?

Deming's ideas really showed their power in Japan. Here's an example: The Ford Motor Company made a car model with transmissions (parts that help the car change gears) from two different places: Japan (made by Mazda) and the United States (made by Ford). Soon after the cars were sold, customers preferred the cars with Japanese transmissions, even waiting longer to get them.

Ford engineers were puzzled because both transmissions were made to the same plans. When they took them apart, they found something interesting. The American parts were good, but the Japanese parts were almost exactly alike and very close to the perfect size. For example, if a part was supposed to be 12 inches long, the Japanese parts were all super close to 12 inches, with very little difference between them. This made the Japanese cars run much smoother and have fewer problems. This showed how Deming's focus on reducing variation and improving quality made a big difference.

Deming taught that improving quality would lower costs, make companies more productive, and help them sell more products. Many people in Japan believe Deming was a key reason for Japan's amazing economic growth after World War II. Japan went from a war-torn country to one of the world's largest economies. Deming's ideas helped them achieve:

- Better product designs that worked well.

- Higher and more consistent product quality.

- Better ways to test products.

- More sales around the world.

What Are Deming's 14 Points?

In the United States, Deming is famous for his "14 Points" for management and his "System of Profound Knowledge." This system helps people understand how businesses and organizations work. It has four main parts:

- Understanding a system: Seeing how all parts of a company work together.

- Understanding variation: Knowing that things naturally differ and how to manage those differences.

- Psychology: Understanding how people think and behave.

- Theory of knowledge: Understanding how we learn and what we can know.

Deming's work greatly improved Japan's reputation for making high-quality products. He had a huge impact on Japanese manufacturing. Even though he was honored in Japan with the Deming Prize in 1951, he only became widely known in the U.S. closer to his death in 1993. President Ronald Reagan gave him the National Medal of Technology in 1987.

Deming's Early Life

William Edwards Deming was born in Sioux City, Iowa. He grew up on his grandfather's chicken farm in Polk City, Iowa, and later on a farm in Powell, Wyoming. His parents, William Albert Deming and Pluma Irene Edwards, were well-educated and believed that learning was very important. His mother was a musician, and his father studied math and law.

Deming came from a long line of early American settlers, including John Deming, who helped found the Connecticut Colony.

Deming's Career Journey

Deming taught statistics at New York University (from 1946 to 1993) and Columbia University (from 1988 to 1993). He also worked as a consultant for private businesses.

In 1927, Deming met Walter A. Shewhart, who worked at Bell Telephone Laboratories. Shewhart created ideas like "statistical control of processes" and the "control chart," which are tools to manage quality. Deming was very inspired by Shewhart's work. He realized that these ideas could be used not just in factories but also in how companies are run. This understanding helped him have a huge impact on businesses around the world after 1950.

In 1936, Deming studied in London, England, with famous statisticians. He also helped edit a book by Shewhart. Deming said that Shewhart was brilliant but sometimes made things hard to understand, so Deming spent a lot of time making Shewhart's ideas clearer.

Deming also developed ways to collect information for the U.S. Census in 1940. During World War II, he taught techniques to improve quality to workers making war supplies. These methods were very useful during the war, but they were not used as much in the U.S. after the war ended.

Deming's Impact in Japan

In 1947, Deming helped plan the 1951 Japanese Census. After World War II, Japan was occupied by the Allied powers, and General Douglas MacArthur asked Deming to help with the census. While in Japan, his skills in quality control led to an invitation from the Union of Japanese Scientists and Engineers (JUSE).

JUSE members had already studied some of Shewhart's ideas. They wanted an expert to teach them more about statistical control to help rebuild Japan. From June to August 1950, Deming trained many engineers, managers, and scholars. He also spoke to top Japanese business leaders, including Akio Morita, who co-founded Sony. Deming told them that improving quality would lower costs, make them more productive, and help them gain more customers.

Many Japanese companies used his methods and achieved amazing levels of quality and productivity. This improved quality and lower cost created a huge demand for Japanese products around the world.

Deming did not want money from the notes of his 1950 lectures. So, JUSE created the Deming Prize in December 1950 to thank him. The Deming Prize is still very important in Japan for quality control.

In 1960, the Prime Minister of Japan gave Deming the Order of the Sacred Treasure, Second Class, on behalf of Emperor Hirohito. This award recognized Deming's help in Japan's industrial rebirth and its success worldwide.

Deming's Later Career

Deming was known for being kind, having a subtle sense of humor, and loving music. He sang in a choir, played drums and flute, and wrote religious music.

From his home in Washington, D.C., Deming continued his consulting work in the United States. For a long time, he was not widely known in his home country. But in 1980, he was featured in an NBC TV show called If Japan can... Why can't we? This show talked about how Japan was becoming a strong competitor to the U.S. in industry. After the show, many American companies wanted Deming's help. He continued to advise businesses around the world until he passed away at 93.

How Deming Helped Ford Motor Company

Ford Motor Company was one of the first American companies to ask Deming for help. In 1981, Ford's sales were dropping, and they were losing a lot of money. Larry Moore, Ford's new Quality Director, asked Deming to help improve quality at Ford.

Deming challenged Ford's way of doing things. He told them that managers were responsible for 85% of all problems in making better cars. To Ford's surprise, Deming talked more about management than about quality itself.

In 1986, Ford released a successful line of cars, the Taurus-Sable. Donald Petersen, who was Ford's chairman at the time, said that the changes at Ford were directly from Deming's teachings. By 1986, Ford became the most profitable American car company, earning more than General Motors for the first time in decades. Ford led the American car industry in improvements.

In 1982, Deming's book Quality, Productivity, and Competitive Position was published. It was later renamed Out of the Crisis in 1986. In this book, he shared his "14 Points for Management." He explained that if managers don't plan for the future, their company will lose customers and jobs. Managers should be judged not just by short-term profits but also by their plans to stay in business, protect investments, and create more jobs by improving products and services. He said that companies need a "long-term commitment to new learning and new philosophy."

Deming's methods, especially his ideas on Total quality management, have been very influential. He received many awards, including an honorary PhD from Oregon State University. In 1987, he was given the National Medal of Technology for his work in statistics and his ideas on management that improved product quality. In 1988, he received the Distinguished Career in Science award.

Deming continued to advise companies of all sizes. He worked with Vernay Laboratories, a rubber manufacturing company, holding seminars for employees and suppliers. His famous "Red Bead Experiment" example helped Vernay make big changes in their manufacturing.

In 1988, Deming joined the Graduate School of Business at Columbia University. In 1990, he founded the W. Edwards Deming Center there to promote excellent business practices.

In 1990, Robert Rodin, the CEO of Marshall Industries, trained with Deming. Marshall Industries saw huge growth, from $400 million to $1.8 billion in sales, which was written about in Deming's last book, The New Economics.

In 1993, Deming published his final book, The New Economics for Industry, Government, Education. This book included his "System of Profound Knowledge" and the "14 Points for Management." It also talked about new ideas for education, like group learning without grades.

Deming's Key Ideas

Deming believed that all managers need to have a "System of Profound Knowledge." This system helps them understand the organizations they work in. It has four main parts that work together:

- Appreciation of a system: This means understanding how all the parts of a business (like suppliers, producers, and customers) work together. It's about seeing the big picture and how everything connects.

- Knowledge of variation: This is about understanding that things are never exactly the same. There's always some natural difference (variation) in quality. Deming taught that you need to know the difference between normal variation and "special causes" (big problems) that create defects. Trying to fix normal variation can actually make things worse.

- Theory of knowledge: This involves understanding how we learn and what we can truly know.

- Knowledge of psychology: This is about understanding human nature and how people behave.

Deming explained that you don't have to be an expert in all four parts to use this system. He said that his "14 Points for Management" naturally come from applying this knowledge to change how businesses are run.

He also said that these four parts are connected. For example, understanding people (psychology) is not complete without understanding variation. A manager needs to know that everyone is different, but also that a person's performance is mostly affected by the system they work in, which is the responsibility of management.

Deming's 14 Points for Management

Deming gave managers 14 important principles to make businesses more effective. These points were first shared in his book Out of the Crisis. They helped start the movement known as Total quality management.

- Have a clear purpose: Always work to improve products and services so the company can compete, stay in business, and provide jobs.

- Accept new ideas: We are in a new economic time. Leaders must learn their responsibilities and lead the way for change.

- Stop relying on inspection: Don't just check for mistakes at the end. Build quality into the product from the very beginning.

- Don't choose suppliers based only on price: Instead, focus on the total cost over time. Work with one supplier for each item and build a long-term, trusting relationship.

- Always improve: Continuously make the system of production and service better to improve quality and productivity, which will always lower costs.

- Train employees: Provide good training for people on the job.

- Lead effectively: The goal of leaders should be to help people and machines do a better job. Leaders themselves also need to improve.

- Remove fear: Make sure everyone feels safe to work effectively for the company without fear.

- Break down barriers: Different departments (like design, sales, and production) must work together as a team to prevent problems.

- Stop using slogans and targets: Don't just tell workers to aim for "zero defects" or higher productivity. These often create bad feelings because most problems are due to the system, not the workers.

- Stop using quotas: Don't set strict production numbers for factory workers. Use leadership instead.

- Stop managing by numbers: Don't just focus on numerical goals. Use leadership instead.

- Give workers pride in their work: Remove things that stop hourly workers from feeling proud of what they do. Supervisors should focus on quality, not just numbers.

- Give managers pride in their work: Remove things that stop managers and engineers from feeling proud of what they do. This includes getting rid of yearly performance reviews.

- Encourage learning: Create strong programs for education and self-improvement for everyone.

- Make transformation everyone's job: Everyone in the company must work together to make these changes happen.

Deming said that a lot of training is needed to give people the courage to change old ways. Every activity and job is part of this process.

The PDCA Cycle

It's a common mistake to think Deming created the Plan-Do-Check-Act (PDCA) cycle. Deming always called it the "Shewhart Cycle for Continuous Learning and Improvement," giving credit to Walter A. Shewhart.

The basic idea of the scientific method (making a guess, doing an experiment, and learning from the results) inspired this cycle. Deming later developed it into the Plan-Do-Study-Act (PDSA) cycle, which includes ideas of learning and improvement.

Seven Deadly Diseases

Deming also identified "Seven Deadly Diseases" that can harm a company:

- Not having a clear, steady purpose.

- Focusing too much on quick profits.

- Judging people by performance reviews or yearly evaluations.

- Managers moving around too often.

- Running a company based only on numbers you can see, ignoring other important things.

- High medical costs.

- High costs from warranty claims, often made worse by lawyers.

He also listed "A Lesser Category of Obstacles," which included:

- Not planning for the long term.

- Relying only on technology to solve problems.

- Trying to copy others instead of finding new solutions.

- Making excuses like "our problems are different."

- Believing that management skills can only be taught in classes.

- Relying on quality control departments instead of everyone being responsible for quality.

- Blaming workers for mistakes when the system (designed by management) is responsible for most problems.

- Relying on checking products for quality instead of improving how they are made.

Deming's ideas, like the Plan-Do-Study-Act cycle, his 14 Points, and Seven Deadly Diseases, have had a huge impact beyond manufacturing. They are used in many different areas, like improving sales processes.

Deming's Personal Life

Deming married Agnes Bell in 1922. She passed away in 1930, a little over a year after they adopted their daughter, Dorothy. In 1932, Deming married Lola Elizabeth Shupe, with whom he wrote several papers. They had two more children, Diana and Linda. Deming was survived by Diana and Linda, and seven grandchildren.

Deming's Passing

W. Edwards Deming passed away peacefully in his sleep at his Washington home on December 20, 1993, at the age of 93, due to cancer. When asked near the end of his life how he wished to be remembered in the U.S., he humbly replied, "I probably won't even be remembered."

Works

- Deming, W. Edwards (1964). Statistical Adjustment of Data. Dover. ISBN 0-486-64685-8. LCCN 64-24416. https://archive.org/details/statisticaladjus00demi.

- Deming, W. Edwards (1966). Some Theory of Sampling. Dover. ISBN 0-486-64684-X. LCCN 66-30538. https://archive.org/details/sometheoryofsamp00will.

- Deming, W. Edwards; Massachusetts Institute of Technology. Center for Advanced Engineering Study (1982). Quality, Productivity, and Competitive Position. Massachusetts Institute of Technology, Center for Advanced Engineering Study. ISBN 978-0-911379-00-6. https://books.google.com/books?id=wlcRXzvi0mEC.

- Deming, W. Edwards (2000). The New Economics: For Industry, Government, Education. MIT Press. ISBN 978-0-262-54116-9. https://books.google.com/books?id=RnsCXffehcEC.

- Deming, W. Edwards (2012). The Essential Deming: Leadership Principles from the Father of Quality. McGraw Hill Professional. ISBN 978-0-07-179021-5. https://books.google.com/books?id=A8g_k4EsyI4C.

- Deming, W. Edwards (2018). Out of the Crisis, reissue. MIT Press. ISBN 978-0-262-35003-7. https://books.google.com/books?id=PTNwDwAAQBAJ.

See also

In Spanish: William Edwards Deming para niños

In Spanish: William Edwards Deming para niños

- Analytic and enumerative statistical studies

- C. I. Lewis

- Common cause and special cause

- Continual improvement process

- Epistemology

- Forrest W. Breyfogle III

- Joseph M. Juran

- Kaizen

- Maestro concept

- Shewhart cycle

- Homer Sarasohn

- Toyota Production System