Western Electric facts for kids

| Subsidiary | |

| Industry | Telecommunications |

| Fate | Absorption, remnants operating as Nokia |

| Successor |

|

| Founded | 1869 |

| Defunct | February 7, 1996 |

| Headquarters | Manhattan, New York City, U.S. |

| Products | Telephones, Central office switches, computers, electrical and electronics parts, and all other telecommunications related products supplied to Bell System companies |

| Parent | AT&T Corporation (1881–1996) |

The Western Electric Company was an American company that designed and made electrical and telephone equipment. It operated from 1869 to 1996. For most of its history, Western Electric was a part of AT&T Corporation. It was the main company that made, supplied, and bought all telephone equipment for the Bell System. This lasted from 1881 until 1984, when the Bell System was broken up.

Because the Bell System had a huge monopoly (meaning they were almost the only company) for telephone service in the United States, Western Electric's equipment was used everywhere. The company also created many new technologies and improved how factories were managed.

Contents

- History of Western Electric

- Leaders of Western Electric

- How Western Electric Became a Monopoly

- Western Electric Factories

- Distribution Centers

- Cool Inventions and Technologies

- Innovations in Manufacturing

- Management Innovations

- National Defense and NASA Projects

- The End of Western Electric

- What Happened Next

- Educational Films

- Famous Employees

History of Western Electric

In 1856, a craftsman named George Shawk bought an electrical engineering business in Cleveland, Ohio.

In January 1869, Shawk teamed up with Enos M. Barton in Cleveland. They made burglar alarms, fire alarms, and other electrical items. Both men used to work for Western Union, a telegraph company. One of their customers was an inventor named Elisha Gray, who was looking for parts for his experiments.

Barton and Gray wanted to grow the company and make new electrical devices. Shawk wasn't interested in such big plans, so he sold his share to Gray. With money from Anson Stager, Gray bought Shawk's part. Gray and Barton then moved their business to Chicago. They officially started their company, called Gray & Barton, on November 18, 1869.

In 1872, Barton and Gray moved the business again in Chicago. They officially named it the Western Electric Manufacturing Company. They made many electrical products, like typewriters, alarms, and lighting. They also worked closely with Western Union, supplying them with equipment.

In 1875, Elisha Gray sold his part of the company to Western Union. This included a special document he had filed for a telephone invention, which was similar to Alexander Graham Bell's. This led to a big legal fight between Western Union and the Bell Telephone Company. In 1879, Western Union stopped trying to be in the telephone business. Bell then bought Western Electric in 1881. This was a very important step for Bell to make sure all telephone equipment was the same and made by one company.

Early Factory Locations

When Western Electric first started, it had five factories. These were in Chicago, New York, Boston, Indianapolis, and Antwerp, Belgium. The locations changed over time. The main office in Chicago moved, and the New York shop moved to a new building. The Boston and Indianapolis factories closed. The Antwerp location stayed until it was sold in 1925.

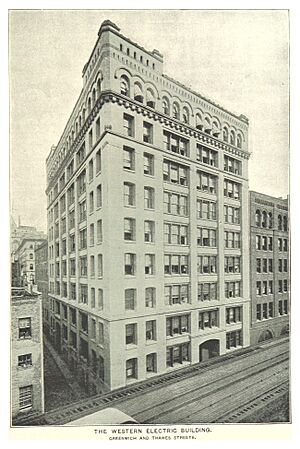

In 1888–1889, Western Electric built a 10-story factory at 125 Greenwich Street in New York City. Here, they made some of the first telephones.

In 1899, Western Electric became the first American company to start a joint business venture in Japan. They bought 54% of the Nippon Electric Company, Ltd.. NEC later became a huge international company making electronics.

Important Events and Changes

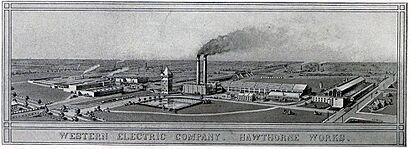

In 1903, Western Electric started building its first big factory, called Hawthorne Works, near Chicago. This factory would become very important.

In 1907, Western Electric and AT&T combined their research and development teams in New York. This helped them improve telephones and equipment as more people started using them.

A sad event happened on July 24, 1915. Employees from the Hawthorne Works were going to a company picnic on a ship called the SS Eastland. The ship rolled over at the dock, and more than 800 people died.

In 1920, Alice Heacock Seidel became the first married woman allowed to keep her job at Western Electric. Before this, married women were not allowed to work there. This decision changed the company's policy and allowed other women to continue working after marriage, even offering maternity leaves.

In 1925, AT&T sold its international factories, including the one in Brussels, Belgium, to ITT. This was done to avoid legal problems about monopolies. Also in 1925, Western Electric's electrical equipment distribution business became its own company, called Graybar Electric Company. It was named after the founders, Elisha Gray and Enos Barton.

The Bell Telephone Laboratories, which was the engineering department of Western Electric, also became its own company in 1925. Western Electric owned half of it, and AT&T owned the other half.

In the 1930s, Western Electric continued to grow. They bought Teletype Corporation, which made teletypewriters. They also bought a plant to recycle old telephone wires and metal. Another factory was bought to make wooden telephone booths.

In 1983, Western Electric announced that some of its oldest and largest factories would close. This included Kearny Works, Baltimore Works, and Hawthorne Works. Many jobs were lost. After the Bell System broke up in 1984, Western Electric's facilities were renamed AT&T Technologies. The three large factories mentioned earlier closed soon after.

Company Logos

Western Electric used different logos over the years. From 1914, they used a statue called Electricity, which was later renamed Spirit of Communication.

Leaders of Western Electric

Western Electric had many presidents who led the company through its history. Here are some of them:

| Period | Name of President | |

|---|---|---|

| 1 | December 1881 – January 1885 | Anson Stager |

| 2 | January 1885 – February 1886 | William Algernon Sydney Smoot |

| 3 | October 1886 – October 1908 | Enos Melancthon Barton |

| 4 | October 1908 – July 1919 | Harry Bates Thayer |

| 5 | July 1919 – August 1926 | Charles Gilbert Du Bois |

| 6 | August 1926 – December 1939 | Edgar Selden Bloom |

| 7 | January 1940 – September 1947 | Clarence Griffith Stoll |

| 8 | October 1947 – December 1953 | Stanley Bracken |

| 9 | January 1954 – September 1956 | Frederick Kappel |

| 10 | September 1956 – March 1959 | Arthur Burton Goetze |

| 11 | March 1959 – December 1963 | Haakon Ingolf Romnes |

| 12 | January 1964 – November 1969 | Paul Albert Gorman |

| 13 | December 1969 – October 1971 | Harvey George Mehlhouse |

| 14 | November 1971 — December 1983 | Donald Eugene Procknow |

How Western Electric Became a Monopoly

In 1915, Western Electric Manufacturing became a new company called Western Electric Company, Inc. It was fully owned by AT&T. This change allowed them to issue a special type of stock.

In the Bell System, telephones were rented to customers by the phone companies. The phones always belonged to the Bell System. Customers paid a monthly fee that included the phone rental and service. This system helped keep basic phone service cheap. When phones broke, Bell System repaired them. This also meant Western Electric phones were built to last a very long time.

AT&T also had strict rules against using phones made by other companies on their network. If a customer wanted to use a different phone, they had to give it to the local Bell company. Then, Bell would rent it back to them for an extra fee. In the 1970s, when more people wanted to buy their own phones, AT&T changed its policy. They started selling the outer part of the phone, but still owned the inside parts. This meant customers still paid a monthly rental fee for the internal components.

After the Bell System broke up in 1983, Western Electric phones could be sold to the public under the brand name American Bell. However, AT&T was not allowed to use the name "Bell" after January 1, 1984.

Western Electric Factories

In 1903, Western Electric started building its first major factory, Hawthorne Works, near Chicago. In 1905, other smaller shops moved into Hawthorne.

More large factories were built in the 1920s. In 1923, construction began on the Kearny Works factory in Kearny, New Jersey. It started making telephone cables in 1925. Kearny Works became the second largest Western Electric plant before the 1930s. In 1929, the Baltimore Works factory in Baltimore, Maryland, also started making cables and wires.

During World War II, Western Electric leased two factories in Lincoln, Nebraska, to make military equipment. They also acquired a factory in St. Paul, Minnesota, in 1944 to restart making telephones for regular people.

After the war, Western Electric needed to make many more telephones. They acquired a former Studebaker plant in Chicago to help with production. They also took over a facility in Winston-Salem, North Carolina, to make telephone switches and circuits.

By 1967, Western Electric had many manufacturing facilities across the country. Here are some of them:

| Facility | Address / Location | Date of occupancy | Principal products / Notes |

|---|---|---|---|

| Allentown Works | Allentown, Pennsylvania | 1948 | microelectronics |

| Atlanta Works | Norcross, Georgia | 1969 | undersea cables, later fiber-optic cables |

| Baltimore Works | Baltimore, Maryland | 1930 | cables, wire, cords; operated until 1984 |

| Buffalo Plant | Tonawanda, New York | 1946 | telephone cords and switches; closed 1977 |

| Burlington Shops | Burlington, North Carolina | 1946 | military equipment (Nike Missile System) |

| Columbus Works | Columbus, Ohio | 1959 | switching equipment |

| Dallas Works | Mesquite, Texas | 1970 | electronic switches and power equipment |

| Denver Works | Westminster, Colorado | 1972 | business phone systems |

| Engineering Research Center (ERC) | Princeton, New Jersey | 1961 | research on manufacturing technologies |

| Hawthorne Works | Cicero, Illinois | 1904 | cables, wire, switching equipment, metal parts; closed 1983 |

| Indianapolis Works | Indianapolis, Indiana | 1950 | consumer telephone sets |

| Kansas City Works | Lee's Summit, Missouri | 1961 | electronics, switching equipment |

| Kearny Works | Kearny, New Jersey | 1925 | cables, wire, switchboards, power supplies; closed 1984 |

| Merrimack Valley Works | North Andover, Massachusetts | 1956 | transmission equipment |

| North Carolina Works | Winston-Salem, North Carolina | 1954 | broadband carrier equipment, capacitors |

| North Illinois Works | Lisle, Illinois | 1970s | electronic switches, computer systems |

| Oklahoma City Works | Oklahoma City, Oklahoma | 1960 | payphones, switching equipment |

| Omaha Works | Omaha, Nebraska | 1958 | crossbar, dial, and PBX equipment, cables |

| Phoenix Works | Phoenix, Arizona | 1968 | cable and wire |

| Reading Works | Reading, Pennsylvania | 1952 | microelectronics |

| Richmond Works | Richmond, Virginia | 1973 | printed circuit technology |

| Shreveport Works | Shreveport, Louisiana | 1967 | business and consumer telephone sets, payphones |

Distribution Centers

Western Electric had different divisions, including manufacturing, service, and distribution. The distribution division was very important. It made sure the Bell System had the equipment and supplies it needed every day or in emergencies.

In 1964, there were 35 Distribution Houses. These places stored equipment and supplies and also had repair shops for the Bell System. They were divided into East and West zones. Here are some of the distribution houses:

| Name | Location | Established | Notes |

|---|---|---|---|

| Atlanta | Service East | 1905 | |

| Boston | Service East | 1908 | |

| Carolinas | Charlotte, North Carolina | 1958 | |

| Cincinnati | Service East | 1904 | |

| Cleveland | Service East | 1912 | |

| Connecticut | Orange, Connecticut | 1913 | Formerly New Haven. |

| Dallas | Service West | 1908 | |

| Denver | Service East | 1903 | |

| Houston | Service West | 1912 | |

| Illinois | Service West | 1904 | Moved from Chicago to West Chicago. |

| Indiana | Indianapolis, Indiana | 1906 | |

| Jacksonville | Service East | 1927 | |

| Kansas City | Service West | 1903 | |

| Long Island | Service East | 1926 | Formerly Brooklyn. |

| Los Angeles | Service West | 1906 | |

| Miami | Service East | 1960 | |

| Michigan | Plymouth, Michigan | 1908 | Formerly in Detroit. |

| Milwaukee | Service West | 1924 | |

| Minneapolis | Service West | 1907 | |

| Nashville | Service East | 1955 | |

| New Jersey | Union, New Jersey | 1926 | Formerly Newark. |

| New Orleans | Service East | 1912 | |

| New York | Service East | 1904 | |

| Omaha | Service West | 1963 | |

| Pennsylvania | King of Prussia, Pennsylvania | 1901 | Formerly Philadelphia. |

| Pittsburgh | Pittsburgh, Pennsylvania | 1904 | Repaired switchboards, teletypewriters, and telephones. |

| Phoenix | Service West | 1958 | |

| Portland | Service West | 1910 | |

| St. Louis | St. Louis, Missouri | 1902 | New building completed in 1948. |

| Salt Lake City | Service West | 1962 | |

| San Francisco | Service West | 1903 | |

| Seattle | Service West | 1907 | |

| Syracuse | Service East | 1953 | |

| Washington | Service East | 1923 | |

| Westchester | Yonkers, New York | 1961 | Provided supplies for New York Telephone. |

Cool Inventions and Technologies

In 1926, Western Electric made the first Bell System telephone where the speaker and microphone were in one piece, called a handset. Before this, telephones had a separate speaker you held to your ear and a microphone on the desk or wall.

Later, in 1930, they made the "D-type" base, which was wider and more stable. They also improved the sound quality by reducing "sidetone," which is when you hear your own voice too loudly in the receiver.

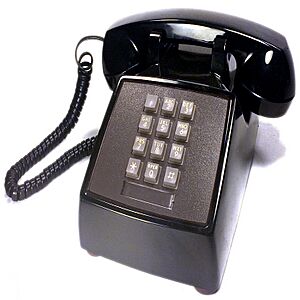

In 1936, the model 302 telephone came out. This was the first Western Electric phone that had the phone, ringer, and other parts all in one unit. It was very popular until the 1950s. Then came the model 500 telephone in 1950, which became the most produced phone model ever! It was updated over time with new materials and quieter dials. The Model 500 was replaced in 1986 by the type 2500, which used dual-tone multi-frequency (DTMF) signaling, also known as Touch-Tone, instead of a rotary dial.

Other cool inventions included color telephones (starting in 1954), the nite-light telephone, the Speakerphone, and the CALL DIRECTOR telephone (all in 1958). They also made the Princess telephone in the 1960s and the Trimline models.

Western Electric also developed advanced switching equipment for phone calls. This included the first electronic switching system (ESS) installed in 1965. The 4ESS was the first digital system for long-distance calls in 1976. In 1981, the 5ESS was used across the United States.

In 1929, Western Electric also got into the movie industry. They created the Western Electric Universal Base, which helped old silent movie projectors play sound films. They also designed powerful horn loudspeakers for cinemas. These speakers were so efficient that a cinema could be filled with sound using only a small 3-watt amplifier. This was a big deal because strong audio amplifiers were not common back then.

Western Electric also played a big role in making equipment for recording and playing professional sound, including:

- The Vitaphone system, which brought sound to movies.

- Technology for making records in the late 1920s.

- The Orthophonic phonograph, which was a record player designed for electrically recorded records.

- Different types of sound systems for movie films, like Westrex optical sound and magnetic sound.

- The Westrex system for recording stereo sound on a single record groove.

Because of these inventions, you can often see the Western Electric/Westrex logo in the credits of many old American films.

During the Cold War in 1950, Western Electric was chosen to build the first test system for SOSUS, an underwater sound system to detect submarines. They were also the main contractor for the Safeguard anti-ballistic missile system in 1975.

Innovations in Manufacturing

Western Electric also spent a lot of effort improving how they made their products.

In 1958, they opened the Engineering Research Center (ERC) near Princeton, New Jersey. This center was one of the first research groups focused only on improving manufacturing processes, not just on new products. Over 400 researchers worked there to bring new manufacturing technologies to the factories. They developed computer models, better quality control systems, new ways to shape metals, and automated ways to assemble circuit boards. They also worked on making fiber-optic cables and using lasers for industrial tasks.

Management Innovations

Western Electric was a leader in how companies were managed.

- They used ideas from Frederick Winslow Taylor about scientific management.

- Walter A. Shewhart developed the control chart at the Hawthorne Works in 1924. This helped improve quality.

- Joseph M. Juran also used statistical analysis to ensure quality at Hawthorne Works.

- At the Hawthorne Works, Elton Mayo studied how changes like lighting or work hours affected how much workers produced. The idea that people change their behavior when they know they are being watched became known as the Hawthorne effect.

- The Hawthorne experiments on factory productivity happened there from 1924 to 1936.

- Western Electric was so well-known for good management that in 1949, President Truman asked them to manage a big defense lab, Sandia National Labs.

National Defense and NASA Projects

In 1957, the U.S. Army chose Western Electric to develop an anti-ICBM defense system called NIKE-ZEUS. Western Electric engineers helped install and test the system at a test site.

In 1960, NASA gave Western Electric a contract to build a tracking system for the Project Mercury program. Western Electric engineers also trained the people who would control flights and operations for Project Mercury.

The End of Western Electric

On January 1, 1984, a new company called AT&T Technologies, Inc. took over Western Electric. Western Electric was split into several parts, each focusing on different types of customers. Telephones made by Western Electric after the breakup were still marked with the company's emblem, but without the Bell System logo.

To save money, consumer telephones were redesigned in 1985. More plastic was used instead of metal in phones like the Model 500 and Princess. In 1986, the Indianapolis Works telephone plant closed, and AT&T stopped making single-line home telephones in the U.S. Business telephones continued to be made at the Shreveport Works plant until 2001. Home telephones were then made in Asia.

Western Electric officially ended in 1995 when AT&T changed the name of AT&T Technologies to Lucent Technologies. Lucent became an independent company in 1996. It later merged with Alcatel to form Alcatel-Lucent, which was then bought by Nokia in 2016.

What Happened Next

After Western Electric closed, many different companies started making telephone equipment. Today, most modern telephones are made in Asia, often using cheaper parts and labor.

Some people chose not to buy their old Western Electric telephones after the AT&T breakup. They continued to rent them from a company called QLT Consumer Lease Services. Even though they paid a lot in rental fees, many people felt these old phones were better quality and more durable than newer ones. Today, many Western Electric telephones are collected by enthusiasts.

Western Electric's old audio equipment from the 1920s and 30s, especially their large horn loudspeakers, are now highly valued by collectors and audiophiles. They are known for their strong build and great sound quality.

New Use of the Name

In 1995, a company called Western Electric Export Corporation bought the right to use the Western Electric brand name and make vacuum tubes and audio equipment. This company, located in Rossville, Georgia, now makes high-end audio products, including a famous vacuum tube called the Western Electric 300B.

Educational Films

Western Electric made many educational and marketing films about its products and inventions. For example:

- "Finding His Voice" (1929) was an animated cartoon that explained how sound was recorded and used in movies with the Vitaphone projector.

- "Bottling Electrons" (1930s) showed how vacuum tubes were made.

- "A Miracle for Mrs. Smith" (1940s) explained how the Bell telephone system worked and how Western Electric made the equipment.

- "Adventure In Telezonia" (1950) was a puppet film that taught people how to use the telephone correctly.

- "A Family Affair" (1955) was a film about using telephones at home and featured actor Steve McQueen.

- "Tools of Telephony" (1956 and 1958 versions) showed the different phones, cables, and switching equipment that Western Electric made and supplied to the Bell System.

- "Speedy Cutover Service" (1984) showed an electronic switching system.

Famous Employees

| Employees | Notes |

|---|---|

| Harold D. Arnold | In 1913, he developed a way to amplify sound in a high-vacuum tube for telephone cables. |

| Edward Craft | He worked at the company from 1902 to 1929. In the 1920s, he decided the company should work on sound systems for movies. He had 70 patents related to electrical communication. |

| W. Edwards Deming | He worked with other experts to become one of the founders of the quality improvement movement. His method for continuous improvement is known as the Plan–Do–Check–Act (PDCA) cycle. |

| George Halas | He worked at Hawthorne Works during the summer and played company sports. He was late to the picnic on the tragic S.S. Eastland in 1915, which saved his life. He later helped start the National Football League and coached the Chicago Bears. |

| Betty Hall | She made vacuum tubes during World War II. After leaving the company in 1944, she served in the New Hampshire House of Representatives for 28 years. |

| Beatrice Alice Hicks | She was the first female engineer at Western Electric in 1942. She worked on long-distance telephone technology and developed a crystal oscillator for aircraft communications. She continued her studies while working and later became a consultant. |

| Mervin Kelly | He started at Western Electric in 1918 as a physicist. He later became a director at Bell Laboratories, leading developments in vacuum tubes and electronics. |

| May Edward Chinn |

| Rebecca Cole |

| Alexa Canady |

| Dorothy Lavinia Brown |