American Precision Museum facts for kids

|

Robbins and Lawrence Armory and Machine Shop

|

|

The American Precision Museum

|

|

| Location | S. Main St., Windsor, Vermont |

|---|---|

| Area | 1.75 acres (0.71 ha) |

| Built | 1846 |

| NRHP reference No. | 66000796 |

Quick facts for kids Significant dates |

|

| Added to NRHP | November 13, 1966 |

| Designated NHL | November 13, 1966 |

The American Precision Museum is a cool place to visit in Windsor, Vermont. It's located in an old factory building from 1846. This building is super important because it's believed to be the first factory in the United States where "interchangeable parts" were made with great accuracy.

Imagine making a toy car where every wheel is exactly the same. If one wheel breaks, you can easily swap it for another identical one. That's what interchangeable parts are! This idea changed how things were made forever. It also started the "precision machine tool" industry. A machine tool is a machine that makes parts for other machines, like screws or parts for guns.

Because of its amazing history, the building was named a National Historic Landmark in 1966. It was also recognized as an International Heritage Site in 1987. This means it's a really special place where important things happened in American industry. The museum has the biggest collection of old machine tools in the U.S. You can see machines that made rifles, sewing machines, and typewriters. It's like a time capsule showing how our modern world began!

The Factory's Story

Building the Robbins and Lawrence Armory

The story of this factory began with a smart mechanic named Richard S. Lawrence. He moved to Windsor in 1838 and started making guns. He teamed up with Nicanor Kendall, another gun maker. Later, a businessman named Samuel E. Robbins joined them.

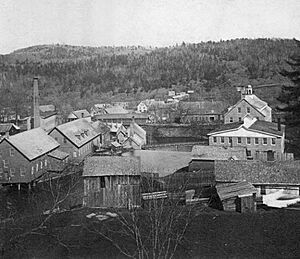

In 1846, these three men decided to try something big. They bid on a government contract to make 10,000 rifles! They won the contract and then built a four-story brick factory next to Mill Brook. Over the next eight years, they worked hard. They built the factory, invented new machines, and made old ones better. They perfected how to make those important interchangeable parts.

Soon, they were not just selling rifles but also their new metal-cutting machines. They sent them all over North America, to England, and even further! The technology they used for guns quickly helped make many other products we use every day.

The factory building was designed to use water power from the brook. Inside, a system of shafts and belts moved power to all the machines. Many windows let in lots of sunlight for the workers. Even today, you can see some of the houses where the factory workers lived nearby. The Connecticut River and the railroad were also important for bringing materials and sending out products.

The Armory Building: 1866–1964

After Robbins and Lawrence, the building had other uses. From 1866, it was a cotton mill for almost 20 years. Then, in 1888, it went back to making machine tools. Later, it was sold to electric companies, first Windsor Electric Light Company, then Central Vermont Public Service Company.

The Museum: 1966 - Present

In 1964, the electric company thought about tearing down the old factory. But Edwin A. Battison, a curator from the Smithsonian Institution who lived in Windsor, had a great idea. He wanted to turn it into a museum! He had already been storing some items in the building since the 1950s.

Battison, who was an expert in mechanical engineering, founded the American Precision Museum in 1966. He became its first director. He used the Robbins & Lawrence Armory to display his amazing collection of historic machine tools, books, and old records.

The armory building is special because it still looks much like a 19th-century factory. It shows us how factories were built and operated back then. In 2001, it was part of a special project called "Save America’s Treasures." In 2003, the museum even received $200,000 to put on a new slate roof, just like the original!

Robbins and Lawrence's Big Impact

The "American System" of Manufacturing

The first part of the Industrial Revolution in America focused on making textiles (cloth). But in 1846, when the Armory was built, a new way of making things was starting: the "American System."

In Windsor, people had already built dams to power sawmills and gristmills. In these small workshops, inventors came up with new products and found ways to make things faster. Windsor and other towns in the Connecticut River Valley became known as "Precision Valley." New industries brought more people and helped towns grow.

How Robbins & Lawrence Changed Things

Robbins & Lawrence are considered pioneers of the precision tool industry for two main reasons.

First, in 1851, Robbins and Lawrence went to London for the Great Exhibition. This was a huge show where countries displayed their best inventions. They showed off their rifles, which were made in Windsor using interchangeable parts. They won a medal! The British Army was so impressed that they ordered 25,000 rifles for the Crimean War. They also bought 141 of Robbins & Lawrence's metal-working machines. This made the company the first to export machine tools on a large scale.

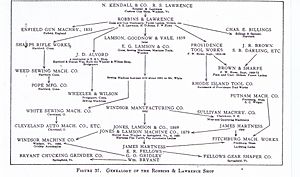

Second, many people who worked at the Robbins & Lawrence factory went on to work for, or even start, other important companies. Because of interchangeable parts, all kinds of machines could be made in large numbers and sold more cheaply. This led to the mass production of sewing machines, typewriters, bicycles, engines, and cars. Precision machine tools, which make standardized parts, are still essential for all the mechanical equipment in our modern world.

Windsor, Vermont: A Hub for Precision

Windsor, Vermont played a huge role in developing precision manufacturing and the machine tool industry in America. The Robbins & Lawrence armory was a place of amazing innovation in the mid-1800s. It was a center for the most advanced technology of its time. Military leaders and business owners came to Windsor to learn about the new "American System" of manufacturing. Workers from Windsor were highly sought after by other growing industries.

By making things more efficiently, the machine tool industry helped spread the idea that many people could own manufactured goods. In the mid-20th century, this industry was the backbone of America's industrial strength. It helped the United States become a world power.

Past and Current Exhibits

Past Exhibits

The museum has hosted many interesting exhibits over the years:

- 1997: Pedal Power: The Bicycle in Industry and Society

- 1999: Carriage Wheels to Cadillac's: Henry Leland and the Quest for Precision

- 2008-2011: From Muskets to Motorcars: Yankee Ingenuity and the Road to Mass Production

- 2012-2014: The Civil War Sesquicentennial at the American Precision Museum: This exhibit celebrated the 150th anniversary of the U.S. Civil War.

- Full Duty: The Civil War Collection of Howard Coffin showed letters, diaries, and photos from Vermont soldiers. It explored their daily lives during the war.

-

- Arming the Union: Gunmakers in Windsor, Vermont told the story of a lesser-known factory called Lamson, Goodnow & Yale. This company operated out of the old Robbins & Lawrence armory. They played a key role in making weapons for the Union Army. The North produced over 1.5 million rifles in about three years, and many of these were made using machines designed in Windsor. This exhibit showed how technology helped save the Union.

Current Exhibits

- 2008 - Present: Working Machine Shop (known as the Innovation Station)

- 2015 - Present: Tool Revolution

- 2016 - Present: Shaping America: Machines and Machinists at Work

This large exhibit explores the people who made big changes possible and the rise of the "American System" of manufacturing. It's the first big exhibit to look closely at Vermont's industrial history. It shows how innovation, craftsmanship, and precision manufacturing shaped American history and culture. This kind of manufacturing helped create the American middle class and led to the consumer culture we have today.

See also

- American system of manufacturing

- Industrial Revolution

- Machine tool builder

- Machine tools

- Machining

- List of National Historic Landmarks in Vermont

- National Register of Historic Places listings in Windsor County, Vermont

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |