Coal mining facts for kids

Coal mining is the process of getting coal out of the ground. Coal is a very important natural resource because it has a lot of energy. Since the 1880s, people have used coal a lot to make electricity. Industries like steel and cement also use coal as a fuel. For example, it helps to get iron from iron ore and to make cement.

Contents

How Coal is Dug Up

There are two main ways to dig up coal: surface mining and underground mining. The method used depends on how deep the coal is.

Surface Mining

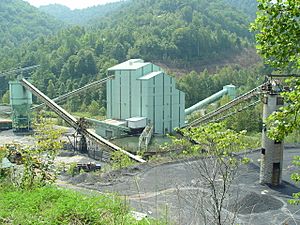

When coal is close to the ground's surface, usually less than about 180 feet (50 meters) deep, miners use surface mining. This means they remove the soil and rocks above the coal. Then, they can dig up the coal without going deep underground. This method can get more of the coal out of the ground than underground methods.

Underground Mining

When coal is much deeper underground, it's too expensive to remove all the soil and rock above it. In this case, miners and their equipment go deep underground. They dig tunnels to reach the coal and then bring it up to the surface. About 60% of the world's coal is dug up this way.

Types of Underground Mining

There are several ways to mine coal underground:

- Longwall mining: This method uses a large machine called a longwall shearer. It has a rotating drum that moves back and forth across a wide coal seam, which can be 1,000 feet (300 meters) or more long. The loosened coal falls onto a conveyor belt that carries it out of the mine. This method produces about half of all underground coal.

- Continuous mining: This method uses a Continuous Miner Machine. It has a big rotating steel drum with strong picks that scrape coal from the seam. This machine works in "rooms" or work areas cut into the coalbed. It can mine a lot of coal very quickly, sometimes 14 tons per minute!

- Blast mining: This is an older method. Miners use explosive materials like dynamite to break up the coal seam. After the blast, the coal is collected and loaded onto special cars or conveyors to be taken out of the mine.

- Retreat mining: In this method, miners remove the pillars (columns of coal) that hold up the mine roof. This allows the roof to collapse as the miners work their way back towards the mine entrance. This method can be risky because it's hard to know exactly when the roof will collapse.

History of Coal Mining

People have been digging up coal for thousands of years, starting with small amounts found near the surface. For example, in Roman Britain, the Romans were already using coal in the late 2nd century AD.

The Industrial Revolution, which started in Britain in the 1700s, relied heavily on coal. Coal powered steam engines, which helped factories run and made transportation much faster. Coal-powered steam engines were used for railways and steamships, helping trade grow around the world.

Until the late 1800s, miners often used picks and shovels to dig coal underground. Children were sometimes employed in these mines, working in dangerous conditions. In the 1880s, machines were invented to cut coal, making the work easier and safer. By 1912, large steam shovels were used for surface mining.

Processing Coal

Before coal can be used, it usually needs to be processed at a special plant. First, the coal is made smaller using machines called sizers and crushers. Then, any parts that could harm equipment, like metal pieces, are removed.

Delivering Coal

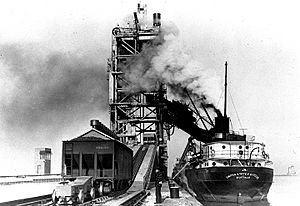

Coal is delivered to customers in several ways. Trucks, conveyors, trains, and ships all help transport coal to factories and power stations where it will be used.

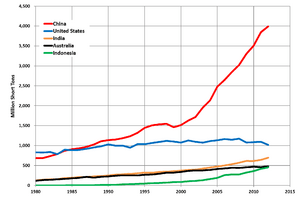

Coal Production Around the World

Coal production has grown fastest in Asia, while it has decreased in Europe. Most coal is used in the country where it is mined. About 16% of hard coal is exported to other countries. More than 50 countries around the world mine coal.

Almost every country has some coal reserves, with about 70 countries having enough to dig up. Based on how much coal is being dug up now, there's enough proven coal to last about 147 years. However, the amount of coal being used is increasing, so some experts think that the peak of coal production might happen sooner in some countries.

Modern Coal Mining

Today, coal mining is more productive than ever before, thanks to new technologies. Modern miners need to be very skilled and well-trained to use complex, state-of-the-art machines and equipment. Many jobs in the industry now require a four-year university degree. Knowing how to use computers is also very important, as most machines and safety systems are computerized.

Environmental Impacts of Coal Mining

Coal mining can have several effects on the environment.

Surface mining completely removes existing plants and trees. It can also change the soil, destroy homes for wildlife, and affect air quality. The land often looks scarred and less natural after mining.

Mine waste can produce acid mine drainage. This acidic water can seep into waterways and underground water sources, which can harm nature and people's health.

If underground mine tunnels collapse, the ground above them can sink. This sinking, called subsidence, can damage buildings and change how streams and rivers flow.

Burning coal is a big reason for global warming because it releases a lot of carbon dioxide. Mining operations can also release methane, another gas that contributes to global warming. The coal mining industry is working to improve its environmental practices.

Images for kids

-

Coal miners exiting a winder cage at a mine near Richlands, Virginia, USA (1974).

-

Surface coal mining in Wyoming in the United States.

-

A coal mine in Frameries, Belgium.

-

Balmain Coal Mine in Sydney, Australia in 1950.

-

The Daikōdō, the first adit of the Horonai mine, was dug in 1879.

-

Abandoned coal mine in Pingxi, New Taipei.

See also

In Spanish: Minería de carbón para niños

In Spanish: Minería de carbón para niños