Escapement facts for kids

An escapement is a special part inside mechanical watches and clocks. It's like a tiny gatekeeper that helps the clock's gear train move forward step by step. This movement makes the clock's hands turn. The escapement also gives a little push to the clock's timekeeping part, like a pendulum or a balance wheel. This push keeps the timekeeper swinging or oscillating, replacing energy lost to friction.

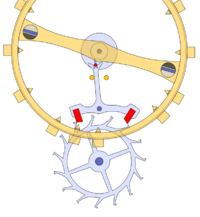

Imagine a coiled spring or a hanging weight powering the clock. This power goes through gears to the escapement. Each swing of the pendulum or balance wheel lets one tooth of the escapement's escape wheel go free. This lets the clock's gears move forward a tiny bit. This regular, tiny movement makes the clock's hands advance steadily. At the same time, the tooth gives the timekeeping part a push. Then, another tooth catches on the escapement's pallet, stopping the wheel again. This sudden stopping is what makes the "ticking" sound you hear in mechanical clocks and watches.

The very first mechanical escapement was called the verge escapement. It was invented in medieval Europe around the 1200s. This invention was super important because it made mechanical clocks possible. The way an escapement is designed greatly affects how accurate a clock is. Improving escapement designs helped make time measurement much better from the 1200s to the 1800s.

Escapements are also used in other machines, not just clocks. Old typewriters used them to move the paper carriage forward each time a letter was typed. Long ago, even some ancient Greek washstands used a type of liquid-driven escapement!

Contents

History of Escapements

The escapement was a key invention that made the first all-mechanical clocks possible. Before this, people used things like water clocks, which measured time by how fast water flowed. The invention of the verge escapement in Europe in the 1200s changed timekeeping. It moved from continuous flow to repetitive swinging motions, like pendulums. These swinging timekeepers could be much more accurate. All modern clocks use some form of oscillating (swinging back and forth) timekeeper.

Early Liquid-Driven Escapements

The idea of a liquid-driven escapement appeared in Ancient Greece around the 3rd century BC. An engineer named Philo of Byzantium described it in a washstand design. It used a spoon that would tip over when full of water, releasing a small object. Philo even mentioned that its design was "similar to that of clocks." This suggests that such mechanisms were already in ancient water clocks.

In China, a Buddhist monk named Yi Xing and an official named Liang Lingzan created an escapement in 723 AD. It was part of a water-powered armillary sphere and clock. Later, during the Song dynasty (960–1279), Chinese clockmakers like Su Song used escapement devices in their huge astronomical clock towers.

However, these were not truly mechanical escapements. They still relied on water flowing to measure time. For example, in Su Song's clock, water filled a container. The escapement would tip the container when it was full, moving the clock's wheels forward. The time between these releases depended on the water's flow rate. The flow rate of liquids can change with temperature or how much liquid is left. Mechanical clocks needed an escapement that could be controlled by a swinging weight, not flowing liquid.

First Mechanical Escapements

The first true mechanical escapement was the verge escapement. It was first used in devices that rang bells before being put into clocks. In the 1300s, it appeared in the first mechanical clocks in Europe. These were often large tower clocks. We don't know exactly when or where it was first used. But things like a sudden rise in clock costs and construction suggest it was developed in the late 1200s. In 1271, an astronomer named Robertus Anglicus wrote that clockmakers were trying to invent an escapement but hadn't succeeded yet. Most experts agree that mechanical escapement clocks existed by 1300.

The earliest detailed description of an escapement was in 1327 by Richard of Wallingford. It was for a clock he built at the Abbey of St. Albans. This design was a bit different from the verge, but it showed how these mechanisms were starting to work.

The verge escapement became the standard for clocks and watches for 400 years. It had some problems with friction and recoil (pushing back). But early clocks were also limited by their foliot balance wheels, which didn't have a balance spring. This meant there wasn't much reason to make the escapement more accurate.

A huge jump in accuracy happened around 1657 with the invention of the pendulum and balance spring. These made the timekeeping parts in clocks and watches swing much more regularly. This made people focus on improving escapements. Over the next two centuries, many new escapement designs were created. About 10 of them became widely used.

In the 1920s, the crystal oscillator and quartz clock were invented. These became the most accurate clocks. This shifted focus to electronic ways of keeping time. Escapement design stopped being the main way to make clocks more precise.

How Escapements Work and Their Accuracy

An escapement's reliability depends on how well it's made and how well it's cared for. A poorly built or maintained escapement can cause problems. It must accurately turn the swings of the pendulum or balance wheel into movement of the clock's gears. It also needs to give enough energy to the pendulum or balance wheel to keep it swinging.

In many escapements, parts slide against each other. For example, in the animation at the top of this article, the anchor's pallets slide against the escape wheel teeth. These pallets are often made of very hard materials, like polished artificial ruby. Even so, they usually need oil to work smoothly. This oil can dry out or get dirty over time. So, clocks need to be oiled regularly. If not, the clock might not work well or stop completely. The parts can also wear out quickly. Modern watches are more reliable partly because they use better oils that last longer, sometimes over five years.

Some special escapements avoid sliding friction. An example is the grasshopper escapement from the 1700s. These might not need lubrication in the escapement itself, though other parts of the clock still do.

The accuracy of a mechanical clock depends on its timing device. If it's a pendulum, its swing time determines accuracy. If the pendulum rod is metal, it can expand or shrink with temperature changes. This changes the pendulum's length and its swing time. Expensive pendulum clocks use special metal alloys that don't change much with heat.

Escapements also play a big role in accuracy. The exact moment the pendulum gets its push affects how precisely it swings. Ideally, the push should be given evenly as the pendulum swings through its lowest point. This is called "being in beat." If the push is uneven, it can make the clock run fast or slow. When the push is even, it gives energy without changing the swing time.

The size of the pendulum's swing also slightly affects its period (time for one swing). To minimize this, pendulum swings are kept as small as possible.

Any escapement with sliding friction needs lubrication. If the lubrication gets bad, friction increases. This means less power is given to the timing device. For a pendulum, more friction makes it less precise. For clocks powered by a spring, the force from the spring changes as it unwinds. For clocks powered by weights, the force can also change as the weight falls.

Smaller clocks and watches don't use pendulums. Instead, they use a balance spring. This is a thin spring connected to a metal balance wheel that swings back and forth. Most modern mechanical watches tick 6 to 8 times per second. The speed depends on the balance spring's stiffness. To keep good time, the stiffness shouldn't change with temperature. So, balance springs use advanced metal alloys. Like pendulums, the escapement must give the balance wheel a small kick each cycle to keep it swinging. And the same lubrication problems can happen, causing the watch to lose accuracy.

Types of Mechanical Escapements

Since the pendulum and balance spring were introduced around 1658, making accurate timepieces possible, hundreds of different mechanical escapements have been invented. But only about 10 have been widely used.

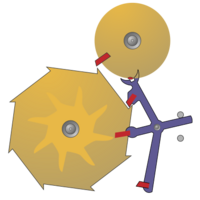

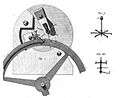

Verge Escapement

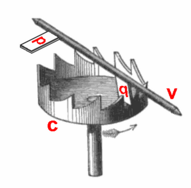

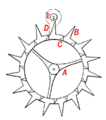

The verge escapement was the first mechanical escapement, from about 1275. It was used in the very first mechanical clocks. It was originally controlled by a foliot, which was a horizontal bar with weights. The escapement has an escape wheel that looks a bit like a crown, with pointed teeth sticking out. A vertical shaft, connected to the foliot, has two metal plates called pallets. As the wheel turns, one tooth pushes an upper pallet, turning the shaft. As that tooth passes, a lower pallet swings into the path of the teeth on the other side. A tooth catches the lower pallet, turning the shaft back the other way, and the cycle repeats.

One problem with the verge was "recoil." Each time a tooth landed on a pallet, the foliot's momentum pushed the crown wheel backward a little before the wheel's force reversed the motion. This caused wear and made the clock less accurate.

The verge was the only escapement used in clocks and watches for 350 years. It was also used in the first pendulum clocks for about 50 years after the pendulum was invented in 1656. However, the verge is the least accurate of the common escapements. After the pendulum was introduced, other escapements started to replace it. By the late 1800s, it was mostly gone.

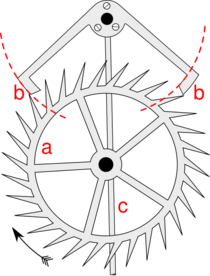

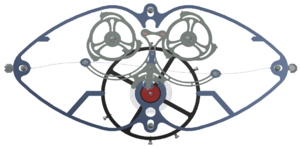

Anchor Escapement

Invented around 1657 by Robert Hooke, the anchor escapement quickly replaced the verge. It became the standard escapement for pendulum clocks until the 19th century. Its big advantage was that it made the pendulum swing in much smaller arcs (3–6 degrees). This made the pendulum almost perfectly regular and allowed for longer, slower-moving pendulums that used less energy.

The anchor escapement is why most pendulum clocks are long and narrow. It also led to the development of the grandfather clock, which was first sold commercially around 1680. This escapement made pendulum clocks so accurate that the minute hand was added to clock faces in the late 1600s (before this, clocks only had an hour hand).

The anchor has an escape wheel with pointed, backward-slanted teeth. An "anchor"-shaped piece pivots above it, rocking side to side and connected to the pendulum. The anchor has slanted pallets that alternately catch on the escape wheel's teeth, getting pushes. It works similarly to the verge escapement and has two of the verge's downsides: 1. The pendulum is always being pushed by an escape wheel tooth. It never swings completely freely, which can affect its accuracy. 2. It's a recoil escapement. The anchor pushes the escape wheel backward during part of its cycle. This causes backlash (play in the gears), more wear, and inaccuracy.

These problems were fixed in the deadbeat escapement, which slowly replaced the anchor in very precise clocks.

Deadbeat Escapement

The Graham or deadbeat escapement was an improvement on the anchor escapement. It was first made by Thomas Tompion in 1675, based on a design by Richard Towneley. It's often credited to Tompion's successor, George Graham, who made it popular in 1715. In the anchor escapement, the pendulum's swing pushes the escape wheel backward. This "recoil" disturbs the pendulum's motion, causing inaccuracy. It also reverses the gears, causing backlash and wear. The main benefit of the deadbeat is that it completely removed recoil.

In the deadbeat, the pallets have a second curved "locking" face. This face is perfectly round around the anchor's pivot point. When the pendulum is at the ends of its swing, the escape wheel tooth rests against this locking face. It gives no push to the pendulum, which prevents recoil. Near the bottom of the pendulum's swing, the tooth slides off the locking face onto an angled "impulse" face. This gives the pendulum a push before the pallet releases the tooth. The deadbeat was first used in very precise regulator clocks. Because it was more accurate, it replaced the anchor in the 19th century. It's used in almost all modern pendulum clocks, except for large tower clocks.

Lever Escapement

The lever escapement, invented by Thomas Mudge in 1750, has been used in most watches since the 1800s. It has two main advantages: 1. It's a "detached" escapement. Unlike other types, the balance wheel only touches the lever for a very short time when it swings through its center. The rest of the time, it swings freely, which makes it more accurate. 2. It's a self-starting escapement. If the watch is shaken and the balance wheel stops, it will automatically start again.

The original design was called the rack lever escapement. Later, a better design called the detached lever escapement was created. British watchmakers used the English detached lever, where the lever was at a right angle to the balance wheel. Later, Swiss and American makers used the inline lever, where the lever is in line with the balance wheel and escape wheel. This is the design used in modern watches. In 1798, Louis Perron invented a cheaper, less accurate version called the pin-pallet escapement. This was used in inexpensive watches in the early 1900s and is still found in cheap alarm clocks and kitchen timers today.

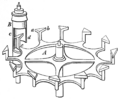

Gravity Escapement

A gravity escapement uses a small weight or a weak spring to give a push directly to the pendulum. Early versions had two arms pivoted near the pendulum's suspension spring. Each arm had a small pallet. When the pendulum lifted one arm enough, its pallet would release the escape wheel. Another tooth on the escape wheel would then start to lift the other arm. This lifting of the arm provides the energy push to the pendulum.

This design was developed from the mid-1700s to the mid-1800s. It became the preferred escapement for large turret clocks (like those in towers). This is because tower clocks have big hands outside that can be affected by wind, snow, and ice. In a gravity escapement, the force from the clock's gears doesn't directly push the pendulum. Instead, it just resets the weights that give the push. So, the escapement isn't affected by changes in the driving force.

The 'Double Three-legged Gravity Escapement' is a common type for accurate tower clocks. The famous clock in Elizabeth Tower at Westminster, which rings London's Big Ben, uses a double three-legged gravity escapement.

Coaxial Escapement

Invented around 1974 and patented in 1980 by British watchmaker George Daniels, the coaxial escapement is one of the few new watch escapements used commercially in modern times.

Its main advantage is that it gives two pushes to the balance wheel. These pushes happen very efficiently, with less friction than in a traditional lever escapement. This design is theoretically better for accuracy.

Today, people don't buy mechanical watches just for their accuracy, as low-cost quartz watches are much more precise. So, watchmakers haven't been very interested in making the special tools needed for new escapements. However, the Omega company did adopt the coaxial escapement in 1990.

Other Modern Watch Escapements

Since quartz watches are so accurate and cheap, new escapement designs are now mostly seen as special features in very expensive, high-end watches. Some luxury watchmakers have introduced new escapements to get attention. However, none of these have been widely adopted by other watchmakers.

One example is the constant escapement, developed by Girard-Perregaux. It uses a special silicon blade that stores elastic energy. This blade snaps to give the balance wheel a consistent push each swing. The idea is that this isolates the balance wheel from changes in the mainspring's power, which can cause inaccuracies in normal escapements.

Other watchmakers like Parmigiani Fleurier and Ulysse Nardin have used silicon springs in their escapements. Some independent watchmakers have even experimented with magnets to make a resonator vibrate at high frequency, replacing the traditional balance spring.

Electromechanical Escapements

In the late 1800s, electromechanical escapements were created for pendulum clocks. In these clocks, an electric switch or light sensor would briefly turn on an electromagnet. This electromagnet would give the pendulum a push. In some clocks, the electric pulse that drove the pendulum also moved the gears to show the time.

Shortt-Synchronome Free Pendulum Clock

In the 1900s, an English clockmaker named William Hamilton Shortt invented a free pendulum clock. It was patented in 1921 and made by the Synchronome Company. This clock was incredibly accurate, losing only about one-hundredth of a second per day.

In this system, the main "master" pendulum keeps time. Its rod is made from a special metal alloy called Invar that changes very little with temperature. This master pendulum swings as freely as possible inside a vacuum chamber and does almost no work. It only touches its escapement for a tiny fraction of a second every 30 seconds.

A second "slave" pendulum turns a ratchet wheel. This triggers an electromagnet slightly less than every 30 seconds. This electromagnet releases a gravity lever onto the escapement above the master pendulum. A fraction of a second later (but exactly every 30 seconds), the master pendulum's motion releases the gravity lever to fall further. As it falls, the gravity lever gives a tiny push to the master pendulum, keeping it swinging.

When the gravity lever falls, it also closes an electrical circuit. This circuit does several things:

- It turns on a second electromagnet to lift the gravity lever back to its top position above the master pendulum.

- It sends an electrical pulse to activate other clock dials (called slave clocks).

- It sends a pulse to a system that keeps the slave pendulum in sync with the master pendulum.

This type of clock became a standard for use in observatories. It was the first clock accurate enough to detect tiny changes in the Earth's rotation speed.

Images for kids

| Chris Smalls |

| Fred Hampton |

| Ralph Abernathy |