Katahdin Iron Works facts for kids

Quick facts for kids |

|

|

Katahdin Ironworks

|

|

Historic view of the iron works. Annotations are as follows: ore kiln (1), top houses (2), furnace (3), casting shed (4) and storage barn (5).

|

|

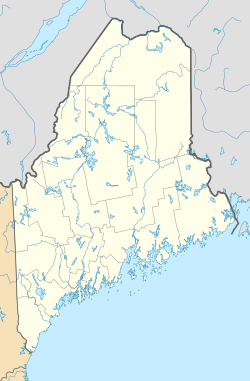

| Nearest city | Brownville Junction, Maine |

|---|---|

| Area | 17.8 acres (7.2 ha) |

| Built | 1843 |

| Architectural style | Bee Hive |

| NRHP reference No. | 69000011 |

| Added to NRHP | December 23, 1969 |

The Katahdin Iron Works is a special historic place in Maine. It is located in a wild area that doesn't have a formal town government. This site was once a busy factory where people made iron. It operated from 1845 to 1890.

At the Katahdin Iron Works, you can still see one of the large ovens, called a kiln, that was used to make iron. Long ago, there was also a railroad that served the community. There was even a big hotel with 100 rooms! This important site was added to the National Register of Historic Places in 1969.

The state of Maine owns this property. It includes a beautiful canyon called Gulf Hagas. This canyon is on the West Branch of the Pleasant River. Gulf Hagas is so special that it's known as a National Natural Landmark. About 1.5 miles (2.4 km) downriver, there's another national landmark. It's called "The Hermitage." This area is about 35 acres (14 ha) of huge Eastern White Pine trees. A group called The Nature Conservancy helps protect these trees. In 2003, the Appalachian Mountain Club bought a large property nearby. It's about 37,000 acres (15,000 ha) and is also named Katahdin Iron Works.

The Iron Making Story

Around 1820, an early explorer named Moses Greenleaf found a mountain with orange, yellow, and red rocks. These rocks were used by the local Abnaki people for paints. In 1843, scientists realized these rocks were a type of iron ore called limonite.

In 1841, Samuel Smith built a road from Brownville, Maine. Then, he built a whole town where the West Branch of the Pleasant River flows from Silver Lake. This town was a "company town." It had a sawmill, a place for workers to live, a store, a town hall, a school, and homes for about 200 families.

Skilled workers built a tall, 55-foot (17 m) rock blast furnace. This furnace used water-powered fans to blow air into it. They also built eighteen stone ovens, called "beehive kilns." These kilns turned wood into charcoal. Charcoal was very important because it was used to make about 2,000 tons (1,800 tonnes) of pig iron each year.

The iron ore from the mountain became the main source for making iron in 1845. The ore was heated to remove unwanted substances like sulfur dioxide. Samuel Smith later sold the factory to David Pingree. Pingree named the business Katahdin Iron Works. When pig iron didn't sell well, Pingree built another factory. This one was a "puddling refinery" to make wrought iron. Wrought iron is a stronger type of iron.

However, the market for wrought iron in Boston was not good. So, the iron works closed down from 1857 until 1863. It reopened when the American Civil War caused a big demand for iron. After Pingree passed away, some businessmen from Bangor, Maine took over in 1876. They called their company the Piscataquis Iron Works Company. They even fixed up the boarding house and turned it into the Silver Lake Hotel for tourists! In 1877, they hired an expert to make the iron better.

The Katahdin Iron Works Railway

A 19-mile (31 km) long railway was built in 1881. It was called the Bangor and Katahdin Iron Works Railway. This railway connected the iron works town to another railway line in Milo, Maine. This other line would later become the Bangor and Aroostook Railroad.

The railway started running in 1882. But then, a big storm caused sparks from the kilns to start a fire. This fire badly damaged the iron plant. By 1885, the rebuilt plant was making very good quality iron. This iron was used for railroad car wheels and even for engines in United States Navy ships.

However, production stopped in 1890. It became too expensive to get enough charcoal from the local forests. It was cheaper for iron makers in Pennsylvania to use a different fuel called coke.

The iron ore deposit at Katahdin Iron Works is very large. It sits on top of another huge deposit of iron sulfide ore. If this deeper deposit is as big as it seems, it could be one of the largest in the world! But because it's in a remote area and the ore isn't the best quality, it's still too expensive to mine today.

The Bangor and Katahdin Iron Works Railroad was leased to the Bangor and Piscataquis Railroad in 1887. The iron works used a lot of wood to make charcoal. By 1888, they had used up most of the local forests. Also, new iron with less sulfur became available from Michigan. Most of the iron-making equipment was moved to Nova Scotia in 1890.

The Bangor and Piscataquis Railroad later became the Bangor and Aroostook Railroad in 1891. This railroad stopped train service to Katahdin Iron Works in 1922. But the postmistress, Sara Green, kept using a special car on the old tracks until the rails were removed in 1933. Today, the state has fixed up the blast furnace and one of the beehive charcoal kilns. These, along with some old building foundations, are all that remain of the busy mill and village.

You can find old records from the mill at the University of Maine's Fogler Library.

Exploring Gulf Hagas

Gulf Hagas is a beautiful canyon that is about 2.5 miles (4 km) long. It was formed by the river flowing through it. The river drops about 500 feet (150 m) as it goes through the canyon. This includes many amazing waterfalls! Some people even call it the "Grand Canyon of the East."

It's a fun trip for hikers. It's an eight-mile (13 km) round trip hike. You can find it as a side trip off the famous 100-Mile Wilderness section of the Appalachian Trail.

| George Robert Carruthers |

| Patricia Bath |

| Jan Ernst Matzeliger |

| Alexander Miles |