Pan amalgamation facts for kids

The pan amalgamation process was an old way to get silver out of ore. It used salt, copper(II) sulfate, and mercury. This method was very popular from 1609 until the late 1800s. Today, it is no longer used.

Before pan amalgamation, people used the patio process to get silver. That process took a long time, often many weeks. In 1609, Alvaro Alonso Barba invented the faster pan process in Potosí, Bolivia. This new method mixed ore with salt and mercury. Sometimes, copper(II) sulfate was also added. The mixture was heated in shallow copper pots. This reduced the time needed to just 10 to 20 hours. Whether miners used the patio or pan process often depended on the weather. Warmer places favored the patio process. Also, the cost of fuel to heat the pans mattered.

The amount of salt and copper(II) sulfate used changed. It could be from one-quarter to ten pounds per ton of ore. When using this process, a lot of mercury was lost. Usually, one to two times the weight of the silver recovered was lost.

The Washoe Process

The Washoe process was a new version of pan amalgamation. It was created in the 1860s by Almarin B. Paul and others. They used it to process ore from the Comstock Lode in Nevada, United States. "Washoe" was an early name for the area. It was also the name of the local tribe who still live there today.

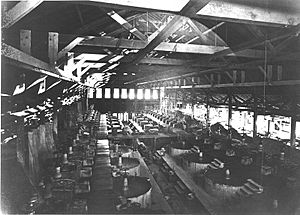

In the Washoe process, copper pans were replaced. Instead, iron tanks with mechanical stirrers were used. Each tank was round. It could hold about 1,200 to 1,500 pounds of ore. This ore had been crushed into a sand-like powder. Water was added to make a thick mix. Then, 60 to 70 pounds of mercury were added. Also, about half to three pounds of salt (sodium chloride) and bluestone (copper(II) sulfate) were put in. A round iron plate called a muller was lowered into the pan. It spun around to stir and grind the ore more. Steam pipes heated the pans. Small bits of iron from the muller and pan wore off. These iron bits turned out to be very important for the process to work.

The Reese River Process

Another version of the Washoe process was developed. This happened in the Reese River mining area near Austin, Nevada. The Washoe process did not work well for some ores. These ores had arsenic or antimony sulfides. They also contained galena or sphalerite.

In 1869, Carl A. Stetefeldt from Reno found a solution. He discovered that roasting the ore with salt helped. This changed the silver sulfides into silver chlorides. These silver chlorides could then be easily recovered. They were collected in the amalgamation pans. This new process was brought to the Reese River District in 1879. It was a great success. Other silver-mining areas also used the Reese River process. These included Georgetown, Colorado, Caribou, Colorado, and Silver Cliff, Colorado.

See also

In Spanish: Método de los cazos para niños

In Spanish: Método de los cazos para niños