Refrigeration facts for kids

Refrigeration is a way of cooling a space, substance, or system to make its temperature lower than the surrounding air. It's like creating an artificial cool zone! This process removes heat from a colder place and moves it to a warmer place. We use refrigeration in many ways, from the refrigerator in your kitchen to huge freezers in factories and even air conditioning systems that keep buildings cool.

Refrigeration has changed our lives a lot. For thousands of years, people tried to keep food from spoiling by salting or drying it. They also used natural cool places like caves or root cellars. But in the 1800s, people started using harvested ice to keep things cold. Then, in the late 1800s and early 1900s, mechanical refrigeration was invented. This meant machines could make things cold, leading to temperature-controlled trains, refrigerator trucks, and the refrigerators and freezers we see everywhere today. This invention helped cities grow in places that used to be too warm, like Houston or Las Vegas, because food could be transported and stored safely.

Contents

A Cool History: How We Learned to Chill Things Out

Early Ways to Keep Things Cold

People have been trying to keep things cool for a very long time! Over 3,000 years ago, in China, people harvested snow and ice and stored it in special cellars. Ancient cultures like the Greeks and Romans also dug large pits, insulated with grass, to store snow and ice, mostly to cool their drinks. The ancient Persians even built special structures called Yakhchals to store ice and keep food fresh. In hot places like Egypt and India, people cooled water by letting it evaporate from shallow clay pots on rooftops at night. This simple idea helped them get cool water.

The Ice Trade: A Big Business

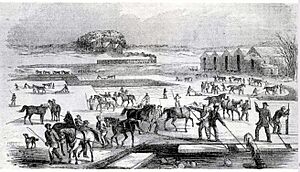

Before the 1830s, not many people in America used ice to keep food cold because ice storage places and iceboxes were rare. Harvesting ice was hard and dangerous work, often done with axes and saws.

However, a clever businessman named Frederic Tudor saw an opportunity. He started harvesting ice in New England and shipping it to warmer places like the Caribbean and the southern United States. At first, he lost money, but by building better icehouses and using well-insulated ships, he greatly reduced how much ice melted. This success encouraged others, especially after Nathaniel Wyeth invented a horse-drawn ice cutter in 1825, making ice harvesting faster and cheaper.

By the 1830s, ice became much more affordable, dropping from six cents a pound to half a cent. Cities like New York and Boston saw a huge increase in ice use. People started using ice and iceboxes to store dairy products, fish, meat, and even fruits and vegetables. This "cooling culture" prepared everyone for the mechanical refrigeration that was coming next.

Inventing Artificial Cold

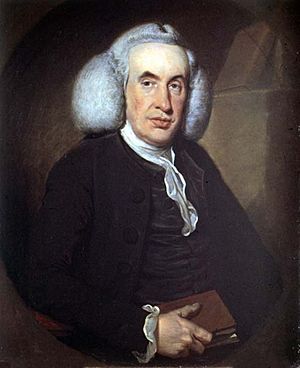

The idea of making cold artificially began in 1755 with Scottish professor William Cullen. He used a pump to create a vacuum over a liquid called diethyl ether. When the ether boiled, it absorbed heat from the air around it, even making a tiny bit of ice!

Later, in 1758, Benjamin Franklin and John Hadley experimented with how fast liquids evaporate to cool things down. They found that evaporating liquids like alcohol and ether could make objects colder than the freezing point of water. They even made a thin layer of ice on a thermometer bulb!

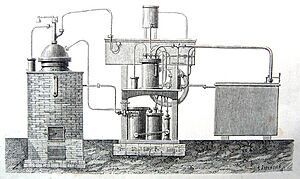

In 1805, American inventor Oliver Evans described a system to make ice using ether under a vacuum. Then, in 1834, Jacob Perkins, an American living in Britain, built the first working system that could continuously make things cold using a "vapor-compression" method. He figured out how to reuse the cooling liquid without waste.

Other inventors followed, like American physician John Gorrie, who built a prototype in 1842. He hoped his system could cool air in homes and hospitals to prevent diseases.

The first practical vapor-compression system was built by James Harrison in Australia in 1851. He used ether, alcohol, or ammonia. His machines were used in breweries and meat-packing plants. In 1859, Ferdinand Carré of France developed the first "gas absorption" refrigeration system, using ammonia dissolved in water. Later, Carl von Linde improved methods for liquefying gases, making it possible to use gases like ammonia and sulfur dioxide as refrigerants.

Refrigeration Goes Commercial

During the American Civil War, cities like New Orleans couldn't get ice from New England anymore. Carré's ice-making machines became the solution. By 1865, New Orleans had three of his machines. In Texas, Andrew Muhl built an ice-making machine in 1867 to help the growing beef industry.

By the 1870s, breweries were the biggest users of harvested ice. But as cities grew, natural ice became polluted. People worried about diseases like typhoid fever from dirty ice. This led to a huge demand for manufactured ice and modern refrigeration.

A major breakthrough for commercial refrigeration was transporting frozen meat across oceans. In 1881, William Soltau Davidson, an entrepreneur from New Zealand, had the ship Dunedin fitted with a refrigeration unit. On February 15, 1882, the Dunedin sailed to London with the first commercially successful shipment of frozen meat. This started the global refrigerated meat industry! Soon, other ships followed, and within five years, many shipments of frozen meat were sent from New Zealand to the United Kingdom. This also helped the meat and dairy industries grow in Australia and South America.

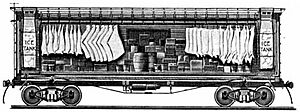

By the 1890s, refrigeration was key to distributing food. Large meat-packing companies like Armour, Swift, and Wilson used expensive refrigeration units in their train cars and storage facilities. By the mid-20th century, refrigeration units were also designed for trucks, allowing perishable goods to be transported by road.

Refrigeration Comes Home

Before electric refrigerators, people used iceboxes. These were insulated cabinets where blocks of ice were placed to keep food cool. Thomas Moore patented a metal-lined butter storage tub in 1803, which was an early version of the icebox. But iceboxes had problems: they could get moldy and smelly, and you had to buy ice daily.

General Electric (GE) was one of the first companies to make household refrigerators. In 1911, they released a gas-powered unit. Later, in 1927, GE introduced the Monitor Top, the first refrigerator to run on electricity.

A big change came in 1930 when Frigidaire created Freon, a new type of refrigerant. These synthetic refrigerants, based on chemicals called chlorofluorocarbons (CFCs), made refrigerators smaller, lighter, and much safer for homes. The price of a refrigerator dropped significantly, making them affordable for many families. By 1940, over half of American households owned a refrigerator.

However, in the 1970s, scientists discovered that CFCs were harming the Earth's ozone layer, which protects us from the sun's harmful ultraviolet rays. Because of this, countries around the world agreed in 1987 (the Montreal Protocol) to stop using these CFC refrigerants. Scientists then developed newer, safer refrigerants that don't harm the ozone layer.

How Refrigeration Changed Our World

Refrigeration has had a huge impact on how we live, what we eat, and where we build our communities.

Growing Cities and New Opportunities

In the past, large cities usually grew near rivers, harbors, or major trade routes. But refrigeration changed this! It allowed cities to thrive in places that were once thought too hot or too far from food sources, like Dallas, Phoenix, and Los Angeles. These "galactic cities" became possible because refrigeration made it easy to transport food and keep people comfortable with air conditioning.

Refrigerated rail cars were a key link between farms and markets. Before them, it was impossible to ship perishable foods like meat, dairy, fruits, and vegetables over long distances. This meant farms could specialize in growing certain crops, knowing they could send them far away. For example, California became known for grapes and peaches, and Mississippi for tomatoes.

Better Food and Health

Refrigeration completely changed our food system. It allowed for the safe handling and storage of perishable foods, meaning we could eat fresh fruits, vegetables, meat, and dairy all year round, even if they were grown far away. This led to a much wider variety of foods in our diets and improved nutrition for many people. Instead of relying on salted or dried foods, we could enjoy fresh options. Studies have even shown that better nutrition from refrigeration contributed to people growing taller and healthier!

Farms also changed. With refrigeration, farmers could produce more food and ship it further. This meant fewer farms were needed, but those that remained became much larger and more productive. Refrigeration on farms helps reduce humidity, prevents bacteria from growing, and keeps produce, meat, and milk fresh for longer.

What Refrigeration Does Today

Today, refrigeration is everywhere! Its most common uses are air conditioning in homes and buildings, and keeping food cold in kitchens, restaurants, and large warehouses. Refrigerators and freezers allow us to store fresh salads, fish, and meats safely for long periods. The best temperature for most perishable food is between 3 and 5 degrees Celsius (37 to 41 degrees Fahrenheit).

In industries, refrigeration is used for many things:

- It helps turn gases like oxygen and nitrogen into liquids.

- It removes water vapor from compressed air.

- It keeps chemical processes at the right low temperatures in factories.

- Metalworkers use it to strengthen steel.

- It's essential for transporting temperature-sensitive goods by trucks, trains, planes, and ships.

Dairy products, meats, poultry, and fish all need constant refrigeration. It was even discovered that eggs should be refrigerated during shipment, not just when they arrive at the store! Refrigeration also helped the sushi and sashimi industry grow in Japan, making it safer to enjoy raw fish.

How Refrigeration Works: The Basics

Refrigeration works by moving heat from one place to another. Imagine your refrigerator: it takes heat from inside the fridge and releases it outside. This process usually involves a special liquid called a refrigerant that cycles through different parts of the system.

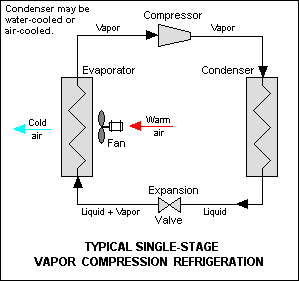

The most common way refrigeration works is called the vapor-compression cycle. Here's a simplified look:

- Evaporator: Inside your fridge, the cold refrigerant liquid absorbs heat from the food. As it absorbs heat, it turns into a gas (vapor).

- Compressor: This gas then goes to a pump called a compressor. The compressor squeezes the gas, which makes its temperature and pressure go up a lot.

- Condenser: The hot, high-pressure gas then flows through coils, usually on the back or bottom of your fridge. Here, it releases its heat into the surrounding room air. As it cools down, it turns back into a liquid.

- Expansion Valve: The high-pressure liquid then passes through a tiny opening called an expansion valve. This causes its pressure to drop suddenly, making it very cold. It's now ready to go back to the evaporator and start the cycle again!

There are other ways to create cold, too! Some systems use special materials that cool down when a magnetic field is removed (magnetic refrigeration), or when they are stretched (elastocaloric refrigeration). Some portable coolers use a method called thermoelectric cooling, which uses electricity to create a temperature difference. Even melting ice in a cooler is a simple form of refrigeration!

See also

In Spanish: Refrigeración para niños

In Spanish: Refrigeración para niños

- Air conditioning

- Cold chain

- Coolgardie safe

- Freezer

- Heat pump

- Icebox

- Refrigerator

- Refrigerator car

- Refrigerator truck

- Vapor-compression refrigeration

- World Refrigeration Day

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |