Gas compressor facts for kids

A gas compressor is a machine that makes a gas take up less space by squeezing it. When you squeeze a gas, its pressure goes up, and it naturally gets hotter.

Compressors are a bit like pumps. Both machines make a fluid (like gas or liquid) have higher pressure. They can also move the fluid through a pipe. The big difference is that gases can be squeezed, so a compressor also makes the gas smaller. Liquids, however, can't really be squeezed, so pumps mainly just move them around.

Contents

Different Kinds of Compressors

There are many types of gas compressors. They generally fall into two main groups:

- Positive displacement compressors: These trap a certain amount of gas and then force it into a smaller space.

- Reciprocating (like a piston moving back and forth)

- Rotary (using spinning parts)

- Dynamic compressors: These use fast-moving parts to speed up the gas, then slow it down to increase pressure.

- Centrifugal (spinning outwards)

- Axial (moving straight along a path)

Let's look at some of the most common types in these groups.

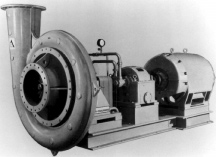

Centrifugal Compressors

Centrifugal compressors use a spinning wheel with blades, called an impeller. This wheel spins very fast and throws the gas outwards, making it move quickly. Then, a special part called a diffuser slows the gas down. When the gas slows down, its speed energy turns into pressure energy.

These compressors are often used in big factories like oil refineries and chemical plants. They can be very powerful, from 100 horsepower up to thousands! They can also create extremely high pressures, sometimes over 10,000 pounds per square inch (psi).

You might also find them in places that make a lot of snow, like ski resorts. They are also used in car engines as superchargers and turbochargers to make the engine more powerful.

Diagonal or Mixed-Flow Compressors

Diagonal or mixed-flow compressors are similar to centrifugal ones. However, the gas moves both outwards and forwards as it leaves the spinning part. A special part then guides the gas to flow straight. These compressors can be smaller than centrifugal ones for the same job.

Axial-Flow Compressors

Axial-flow compressors use many fan-like spinning blades, called rotor blades. Each set of spinning blades pushes the gas forward and squeezes it a little more. After each set of spinning blades, there are stationary blades, called stator vanes. These guide the gas to the next set of spinning blades.

The space for the gas gets smaller and smaller as it moves through the compressor. This helps keep the gas flowing smoothly. Axial-flow compressors are usually found in large gas turbine engines, like those in jet planes. They almost always have many stages (sets of blades) to get the job done.

Reciprocating Compressors

Reciprocating compressors use pistons that move back and forth, just like in a car engine. These pistons are driven by a spinning rod called a crankshaft. You can find them as small, portable units or large, stationary ones. They can have one or many stages of compression.

Small ones, from 5 to 30 horsepower, are common in car repair shops. They are often used for short bursts of work. Larger ones, up to 1000 horsepower, are still used in big factories. They can create very high pressures, over 5000 psi. For some jobs, like compressing air, multi-stage reciprocating compressors are very efficient. However, they can be bigger, louder, and more expensive than other types.

Rotary Screw Compressors

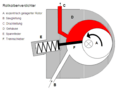

Rotary screw compressors use two spinning, spiral-shaped screws that fit together. As these screws turn, they trap gas and force it into a smaller and smaller space. These compressors are great for jobs that need continuous power in businesses and factories. They can be portable or stationary.

They range from small 3 horsepower units to very large ones over 500 horsepower. They can also create high pressures, over 1200 psi. You often see them with road repair crews, powering air tools. They are also used in many car engine superchargers because they work well with piston engines.

Scroll Compressors

A scroll compressor uses two spiral-shaped parts that fit into each other. One spiral stays still, while the other one orbits around it without actually spinning. This motion traps pockets of fluid (like gases or even liquids) and squeezes them.

These compressors are known for being smoother, quieter, and more reliable than some other types.

Diaphragm Compressors

A diaphragm compressor uses a flexible sheet, or membrane, to squeeze the gas. Instead of a piston, this membrane moves back and forth, driven by a rod and a crankshaft. The important thing is that only the membrane and the compressor's inner box touch the gas. This makes them very useful for compressing gases that need to stay super clean.

Diaphragm compressors are used for gases like hydrogen and CNG (Compressed Natural Gas).

Other Compressor Facts

Many air compressors sold to the public come with a tank to hold the squeezed air. Some compressors use oil to lubricate their parts, while others are "oil-free." Oil-free compressors are good because they prevent oil from getting into the air. For special uses, like filling scuba tanks, it's very important that the air is clean and free of oil.

How Temperature Changes During Compression

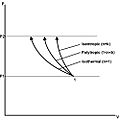

When you squeeze a gas, its temperature naturally goes up. Think about pumping up a bicycle tire – the pump gets warm!

- Getting Hotter: When a gas is squeezed quickly, it gets hotter because all the work put into squeezing it turns into heat inside the gas. This is like when you rub your hands together fast, they get warm.

- Keeping Cool: To make compressors work better, especially in big machines, engineers try to cool the gas as it's being squeezed. This helps the compressor be more efficient.

Squeezing in Stages

Because squeezing gas makes it hot, big compressors often do it in stages. This means they squeeze the gas a little bit, then cool it down, then squeeze it more, and cool it again. This makes the whole process more efficient.

For example, a typical diving air compressor squeezes air in three stages. If each stage squeezes the air 7 times, the compressor can make the air 343 times stronger than normal air pressure (7 x 7 x 7 = 343). This is how they fill scuba tanks to very high pressures!

Where Compressors Are Used

Gas compressors are used in many places where you need gas at higher pressures or in smaller spaces:

- Moving natural gas through pipelines from where it's found to homes and factories.

- In big factories like oil refineries and chemical plants to squeeze gases used in making products.

- In refrigerators and air conditioners to move heat around and keep things cool.

- In gas turbine engines (like in power plants) to squeeze the air needed for burning fuel.

- Storing pure gases in small, high-pressure cylinders for medical uses, welding, and other jobs.

- Powering all sorts of pneumatic tools in factories, construction, and workshops.

- As a way to transfer energy, like powering pneumatic equipment.

- In pressurized aircraft to keep the air inside breathable at high altitudes.

- In jet engines to provide the air needed for the engine's combustion.

- For SCUBA diving and other life support systems to store breathing gas in diving tanks.

- In submarines to store air that helps them control their buoyancy.

- In turbochargers and superchargers to make car engines more powerful.

- In trains and heavy trucks to provide compressed air for their brakes and other systems.

- For everyday things like filling tires with air.

Related pages

Images for kids

-

A small, sealed compressor in a common refrigerator.

See also

In Spanish: Compresor (máquina) para niños

In Spanish: Compresor (máquina) para niños