Factory system facts for kids

The factory system is a way of making things using machines and a special way of working called the division of labor. Imagine a big building where many people work together, each doing a small part of a bigger job. This system needs expensive machines and buildings. Because of this, factories are usually owned by rich people or companies. They hire workers to operate the machines and do the work.

Using machines and dividing up the work meant that workers didn't need as much skill. It also meant that factories could make many more products much faster. The factory system first started in Britain during the Industrial Revolution in the late 1700s. Later, it spread all over the world. It replaced an older way of working called the putting-out system, where people made goods in their homes.

The main thing about the factory system is using machines. These machines were first powered by water or steam. Later, they used electricity. Other important parts of this system include making many products at once (called economies of scale), bringing all the work into one central place, and making parts that are all the same size and shape (called interchangeable parts).

What Makes a Factory System?

The factory system has several key features that make it different from older ways of making things:

How Production Works

- Ownership: In a factory system, the workers usually don't own the business. Instead, the owners (often called capitalists) provide everything. This includes the machines, buildings, and raw materials. They also manage the factory and sell the products. They are responsible for any money lost.

Workers and Their Skills

- Using Different Skills: Before factories, skilled craftspeople often made a whole product, like a pair of shoes. But in factories, work was broken down into smaller steps. Most workers were either low-skilled, operating machines, or unskilled, moving materials. This is called the division of labour. Even the older putting-out system used some division of labor.

Making Many Products

- Making More for Less: Factories could make a lot more products than the old home-based systems. Because they made so many goods, factories needed good ways to transport them. This allowed products to be sold in many places. Factories used fewer workers to make each product, which made things cheaper to produce.

Where Factories Were Built

- Location, Location, Location: Early factories often needed water power. So, they were built near rivers or canals. This also helped with transporting goods. As steam engines and railroads became more common, factories could be built further away from water, closer to railroads for easy shipping.

Bringing Work Together

- Centralized Work: The machines used in factories were often big and expensive. Most home workers couldn't afford or maintain them. So, workers and machines were brought together in one central factory building. These buildings were designed to hold the machines and manage the flow of materials. Early factories often had many floors to help power machines. Larger factories might have different buildings for different steps of production.

- Some dangerous jobs, like metal casting or blacksmithing, were usually done in separate buildings for safety.

- Early steam engines were quite large, even the smallest ones. This meant that many small workshops couldn't use them. So, until electricity became common in the early 1900s, many workshops used hand power or rented space in buildings that provided central power.

Making Things Uniform

- Same Size, Same Quality: Factory-made parts were made to exact sizes. For example, all shoe soles would be the same size. This was possible because machines could be very precise. Managers also checked the quality of the products. Many machine operations, like sewing, were better than hand methods. By the late 1800s, metal parts that could be easily swapped out became very common.

- Steady Supply: Factories could produce and deliver a steady amount of goods.

Workers in factories were paid either a daily wage or for each piece they made. Sometimes they were paid with money, housing, meals, or goods from a company store. Paying by the piece became difficult as factories made more and more products. Later, the production line became popular. Here, workers did specific tasks at a set speed, keeping up with the flow of work.

History of Factories

Early Beginnings

- Ancient Times: Even in Ancient Sumer around 3000 BC, people started to use a form of the factory system. They also used the division of labor to make things.

First Mills

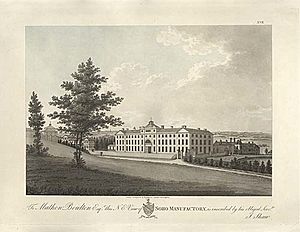

- Early Factories: One of the very first factories was John Lombe's water-powered silk mill in Derby, England, which started in 1721. By 1746, a brass mill near Bristol was making brass and turning it into pans and other goods. Workers even lived on site. Other important early factory owners included Josiah Wedgwood (who made pottery) and Matthew Boulton (who ran the Soho Manufactory).

Cotton and Machines

- Cotton Spinning: The factory system really took off when machines were invented to spin cotton.

- The first factories that did everything – from spinning cotton to dyeing and weaving it into finished cloth – were in Waltham and Lowell, Massachusetts, in the United States. These became known as the Lowell Mills.

- The Bridgewater Foundry, which opened in 1836, was one of the first factories to use modern ways of moving heavy materials, like cranes and train tracks inside the buildings.

Richard Arkwright's Impact

- Arkwright's Role: Richard Arkwright is often seen as a key person in the growth of factories. After he invented his water frame machine in 1769, he built Cromford Mill in England. This factory system was a new way to organize work. It was needed because the new machines were too big to fit in a worker's home. Factory workers often worked long hours, from dawn until dusk, six days a week, much like farmers did.

Better Tools and Parts

- Machine Tools: In the late 1700s, machines started to replace skilled craftspeople. In 1774, John Wilkinson invented a way to make cannon barrels perfectly straight. He then used this method to make parts for James Watt's steam engines. This machine is sometimes called the first machine tool.

- Interchangeable Parts: Making many products with parts that were all the same size was first done in 1803. This happened at the Portsmouth Block Mills in England. They made 130,000 sailing blocks each year for the British Royal Navy. This idea of interchangeable parts later became very popular in America, where it was called the American system of manufacturing.

How Factories Changed Society

Before factories, much of the work was done in homes. This was especially true for weaving cloth. When machines started making goods, they could produce them much cheaper. This made it hard for people working at home to earn enough money.

Growth of Cities

- City Living: Factory workers often lived close enough to walk to work. This was before bicycles and electric streetcars became common in the 1890s. So, the factory system helped cities grow. Many people moved from the countryside to towns to find jobs in factories. Some factories even built dormitories (living spaces) for their workers, especially for young women.

Challenges and Changes

- Protests: The change to factories was not always easy. For example, a group of English workers called Luddites formed in the 1810s. They protested against the new machines and sometimes even broke them. They were continuing a tradition of workers who didn't like machines that saved labor. Some inventors, like John Kay, faced problems when they developed their machines.

- Working Hours: Until the late 1800s, it was common for people to work 12 hours a day, six days a week, in most factories. However, long hours were common in many jobs, not just factories.

- Fair Conditions: People started debating if the factory system was fair. Workers complained about poor working conditions before laws were passed to protect them. One issue was women's pay; they often earned much less than men.

- Child Labor: Child labour also became a big part of the factory system. In the early 1800s, going to school was not required. Many families needed their children to work to help earn money. Children worked on farms and made goods at home too. Besides factories, children also worked in mines. Later, new machines helped reduce the need for child labor. For example, an automatic glass-bottle blowing machine around 1890 helped end child labor in that industry. Over time, more children started going to school.

- Improving Conditions: Some factory owners tried to make things better for their workers. Robert Owen was one of the first reformers. He worked to improve conditions at his New Lanark mills and is known as an early thinker in the socialist movement.

- Economic Hardship: Some thinkers, like Karl Marx, worried that the factory system would lead to very low wages for workers. This was true in some parts of England. The British Agricultural Revolution had already reduced the need for farm workers, forcing them to find jobs wherever they could. Conditions became very bad during economic downturns, like the one in the late 1830s and early 1840s. The Irish famine (1845–1850) also brought many Irish immigrants to work in English and American factories.

- Friedrich Engels wrote a famous book, The Condition of the Working Class in England in 1844, about the tough lives of factory workers. However, by the late 1880s, Engels noted that many of the extreme problems he wrote about had improved.

See also

- Adam Smith

- Arnold Toynbee (historian, born 1852)

- Assembly line

- Mass production

- Mechanization

- Productivity-improving technologies

| Precious Adams |

| Lauren Anderson |

| Janet Collins |