Glass production facts for kids

Glass production is all about making glass! There are two main ways we make glass today: the float glass process, which creates flat sheets of glass (like for windows), and glassblowing, which is used to make bottles, jars, and other containers. People have been making glass in many different ways throughout the history of glass.

Contents

- How Glass Containers Are Made

- Making Flat Glass: The Float Glass Process

- Big Names in Flat Glass Production

- Glass Factories and the Environment Around Them

- See also

How Glass Containers Are Made

Modern factories that make glass containers are usually split into three main parts: the "batch house," the "hot end," and the "cold end."

- The batch house is where all the raw materials (like sand and soda ash) are stored and mixed.

- The hot end is where the magic happens! This is where the glass is melted and shaped into bottles or jars.

- The cold end is the final stage, where the glass products are checked for quality and packed up for shipping.

Getting Started: The Batch House

The batch house is like the kitchen of a glass factory. It holds huge amounts of raw materials in big storage containers called silos. These silos can hold enough material for several days of production! Sometimes, the materials are also cleaned, dried, or even pre-heated here.

Whether it's done by machines or by hand, the batch house carefully measures, mixes, and sends the exact recipe of raw materials (called the "batch") to the furnace. This mix enters the furnace through a special opening called the "dog house" or "batch charger." The exact recipe changes depending on the type of glass being made, its color, how good it needs to be, and what raw materials are available.

The Hot End: Melting and Shaping Glass

The hot end is where the raw materials turn into molten (melted) glass and are then shaped into products. The batch goes into the furnace, then moves to the shaping machines, gets special internal treatments, and finally goes through an annealing oven.

Glass changes how it flows (its viscosity) at different temperatures. Here's a simple way to think about it:

| What it means | Temperature (approximate) |

|---|---|

| Melting Point: Glass becomes a smooth liquid, ready to be mixed. | Very hot! (around 1575°C / 2867°F) |

| Working Point: Glass is soft enough to be pressed or blown into shapes. | Hot (around 1050-1200°C / 1922-2192°F) |

| Softening Point: Glass starts to sag under its own weight. | Still very hot (around 700-800°C / 1292-1472°F) |

| Annealing Point: Internal stress in the glass is removed. | Warm (around 500-580°C / 932-1076°F) |

| Strain Point: Glass is solid and strong, but still a bit flexible. | Cooler (around 450-500°C / 842-932°F) |

Heating Up: The Furnace

The raw materials (the batch) are fed into the furnace slowly and steadily. These furnaces are heated by natural gas or fuel oil and can reach incredibly high temperatures, up to 1,575°C (2,867°F)! The temperature limit depends on how strong the furnace materials are and what kind of glass is being made.

Newer furnaces sometimes use electric heating, which is more energy-efficient and helps reduce pollution. These furnaces use special electrodes made of materials like molybdenum to conduct electricity and create heat.

Shaping the Glass: Forming Process

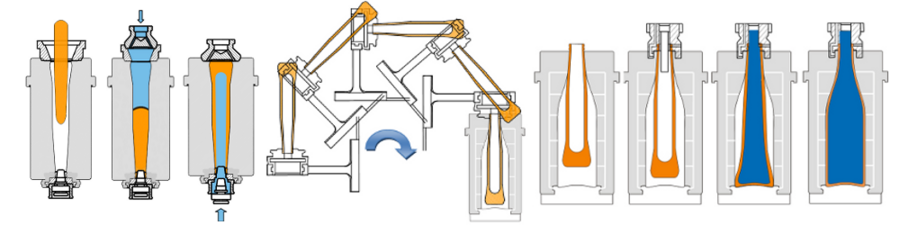

There are two main ways to make glass containers: the "blow and blow" method (for bottles with narrow necks) and the "press and blow" method (for jars and wider-necked containers).

Both methods start the same way: a stream of molten glass, which is very soft and plastic-like (around 1050–1200°C or 1922–2192°F), is cut by a special blade. This creates a solid chunk of glass called a "gob." Each gob is carefully weighed to be just the right amount for one bottle. The gob then falls by gravity into a "blank mould," which is made of two halves that clamp shut.

In the blow and blow process:

- Air is blown into the gob, forcing it into a "ring mould" to create the "finish" (the top part of the bottle, like where the cap screws on).

- This first blow creates a hollow, partly formed container called a "parison." The parison is much smaller than the final bottle.

- The parison is then moved to a "final mould."

- More compressed air is blown into the parison, making it expand and take its final shape inside the mould.

In the press and blow process:

- Instead of air, a long metal plunger presses the glass into the ring and blank moulds to form the parison.

- After the parison is formed, the process continues like "blow and blow," with the parison being transferred to the final mould and blown into its final shape.

Once the container is shaped, a "take-out" mechanism picks it up and places it on a "deadplate" to cool slightly. Then, "push out paddles" gently move the bottles onto a conveyor belt, ready for the next step: annealing.

The Machines That Make Glass

The machines that form the glass containers are complex, with many moving parts. They are usually powered by compressed air and are carefully timed by computers to make sure every movement is perfect.

The most common type of machine is the individual section (IS) machine. Imagine a long row of identical sections, each one capable of making containers. Gobs of glass are fed into each section. These machines can make one, two, three, or even four containers at the same time!

Glass factories use huge compressors to provide all the compressed air needed for these machines. Recently, newer machines use "servo drives" (like advanced robots) for even better control over the shaping process.

Making glass creates a lot of waste heat. This heat, along with any unused molten glass (called "cullet"), is usually cooled down with water. Factories often have large cooling towers to manage all this heat.

Making the Inside Stronger: Internal Treatment

Some glass containers, especially those for drinks like spirits, get a special treatment to make the inside more resistant to chemicals. This is called "internal treatment" or "dealkalization." It involves injecting a gas (containing sulfur or fluorine) into the hot bottles. This treatment helps prevent the glass from breaking down or changing the pH of the product inside.

Cooling Down Slowly: Annealing

When glass cools too quickly or unevenly, it can become weak and easily break due to internal stresses. To prevent this, glass containers go through a process called annealing.

An annealing oven, known as a lehr, heats the containers to about 580°C (1,076°F) and then slowly cools them down over 20 to 60 minutes, depending on how thick the glass is. This slow cooling removes any stresses, making the glass strong and durable.

The Cold End: Finishing Touches

The cold end of the factory is where the glass containers get their final touches before they are ready to be shipped. This includes applying a protective coating, inspecting for flaws, labeling, and packaging.

Protective Coatings

Glass containers usually get two coatings.

- The first is applied at the hot end (before annealing). It's a very thin layer of tin oxide or titanium, which helps the second coating stick better.

- The second coating is applied at the cold end (after annealing). This is usually a layer of polyethylene wax, applied as a water-based liquid. This makes the glass slippery, protecting it from scratches and preventing bottles from sticking together on the conveyor belts.

These coatings make the glass surface almost unscratchable. While they don't make the glass stronger, they help it keep its original strength by preventing surface damage.

Checking for Quality: Inspection Equipment

Every single glass container is inspected! Automatic machines, and sometimes people, check for all sorts of flaws. Common problems include tiny cracks called "checks," or "stones," which are small pieces of the furnace lining or sand that didn't melt properly. Stones are especially bad because they can cause the glass to shatter if it experiences sudden temperature changes. Other defects include bubbles ("blisters") or walls that are too thin. A "tear" can happen if the glass sticks to the mould during shaping.

Besides rejecting bad containers, the inspection machines also collect information. They can tell which mould made a faulty bottle by reading a special code (a number or dots) stamped on the container. This helps factory workers fix problems quickly. Workers also manually check samples for visual and size accuracy.

Adding Labels: Secondary Processing

Sometimes, glass factories also offer labeling services. One special method for glass is Applied Ceramic Labelling (ACL). This is like screen-printing a design onto the container using a special paint that is then baked on, making it permanent. Think of the old Coca-Cola bottles with their painted-on logos – that's ACL!

Getting Ready for Shipment: Packaging

Glass containers are packaged in different ways. In Europe, they are often stacked on large pallets, with 1,000 to 4,000 containers per pallet. Automatic machines (palletisers) arrange and stack the containers with sheets separating the layers. Other packaging options include boxes or even hand-sewn sacks. Once packed, these "stock units" are labeled, stored in a warehouse, and eventually shipped out.

The Business of Glass Making

Making glass containers is a well-established industry, especially in developed countries. In 2009, the world needed about 52 million tonnes of flat glass. The United States, Europe, and China use most of this, with China's use growing a lot.

Glass factories are usually located close to where their products are sold because glass is heavy and bulky, and the raw materials (sand, soda ash, limestone) are generally easy to find. A typical glass furnace holds hundreds of tonnes of molten glass and can't be easily turned off. Factories run 24 hours a day, 7 days a week! This means it's hard to quickly change how much glass is produced.

Building new furnaces and machines costs millions of dollars and takes a long time to plan. So, factories usually make products based on predictions of what customers will need. A typical factory might produce 1 to 3 million containers every day!

Even though it's an old industry, glass is still very popular with consumers and is seen as a "premium" (high-quality) packaging choice.

Glass and the Environment: Lifecycle Impact

Glass containers are completely recyclable! Many countries encourage recycling by keeping the price of "cullet" (broken or waste glass) high, which makes it worthwhile to collect and return glass. Some countries, like those in Scandinavia, have very high recycling rates (over 95%).

Glass containers can also be reused, especially in developing countries. However, it's not always clear if washing and reusing containers is better for the environment than melting them down and making new ones. Factors like the water and chemicals used for washing, and the fact that single-use containers can be made much lighter (using less glass and energy), need to be considered. Also, companies worry about the safety risks of reusing containers if they don't know their full history.

It's tricky to say exactly how glass containers compare to other packaging types like plastic, cardboard, or aluminium in terms of environmental impact. Scientists are still studying this to get a complete picture.

Making Flat Glass: The Float Glass Process

Float glass is the type of flat glass used for modern windows. It's made by floating molten glass on a bed of molten metal, usually tin. (In the past, lead or other low melting point metals were sometimes used.) This clever method makes sure the glass sheet has a perfectly uniform thickness and very flat surfaces.

Most float glass is "soda-lime glass," which is the common type of glass. However, smaller amounts of special types like borosilicate glass (used for heat-resistant items) and glass for flat panel displays are also made this way. This process is also known as the Pilkington process, named after the British company Pilkington and Sir Alastair Pilkington, who invented this technique in the 1950s.

Big Names in Flat Glass Production

Some of the largest flat glass producers in the world include Asahi Glass, Nippon Sheet Glass, Guardian Industries, and Saint-Gobain.

Glass Factories and the Environment Around Them

Like any large industrial facility, glassworks can have some local environmental effects. Since many factories have been in the same spot for a long time, homes and cities have grown up around them. The main impacts on nearby areas can be noise, water use, water pollution, air pollution (from nitrogen oxides and sulfur oxides), and dust.

- Noise: The forming machines, powered by compressed air, can be quite loud (up to 106 dBA). The noise level in the neighborhood depends on the factory's layout. Truck movements (bringing in raw materials and taking out finished products) also add to the noise. A typical factory moves about 600 tonnes of material every day!

- Water Use: Water is used to cool the furnace, compressors, and any unused molten glass. Factories can use as little as one tonne of water for every tonne of glass melted. About half of this water evaporates for cooling, and the rest becomes wastewater.

- Water Pollution: Most factories use water mixed with oil to cool and lubricate the blades that cut the glass gobs. This oily water can mix with the wastewater. Factories usually have equipment to clean this water, but its effectiveness can vary.

- Air Pollution:

* Nitrogen oxides (NOx) are produced when gas burns in the furnaces. Some factories use liquid oxygen to reduce this, but it's an expensive process. * Sulfur oxides (SOx) are also produced during glass melting. Factories can adjust the raw material mix or use special "scrubbers" to clean the exhaust fumes.

- Dust: The raw materials for glass are often fine powders or grains. Even with control systems, some dust can escape. Cullet (broken glass) also creates fine glass particles when it's moved around.

See also

- Mirrors

- Blow moulding

- Borosilicate glass

- Boston round (bottle)

- Drinkware

- Float glass

- Glass disease

- Glass Queen

- Glassmakers' symbol

- History of glass

- Irving Wightman Colburn

- Packaging and labelling

- Wine bottle

- Cage cup

| Toni Morrison |

| Barack Obama |

| Martin Luther King Jr. |

| Ralph Bunche |