Microtechnology facts for kids

Microtechnology is all about creating and working with super tiny things! It focuses on technology where the parts are about one micrometre (that's one millionth of a metre, or 1μm) in size. Imagine something so small you can barely see it with a powerful microscope – that's the world of microtechnology.

This field looks at how to make and control structures that are incredibly small. It involves understanding physical and chemical processes at this tiny scale.

Contents

How Microtechnology Grew

Around the 1970s, scientists made a big discovery. They found that by putting many tiny transistors onto a single chip, they could build amazing electronic circuits. These circuits worked much better, did more things, and were more reliable. Plus, they cost less to make and could be produced in huge numbers! This breakthrough started what we call the Information Revolution.

More recently, scientists learned that not just electronic parts, but also mechanical parts, could be made super small. They could also be made in large batches. This promised to bring the same benefits to mechanical devices that integrated circuits brought to electronics.

Think of it this way: electronics give our modern systems their "brains." But micro-mechanical devices can be the "eyes and ears" or "hands and feet." They act as sensors (to detect things) and actuators (to make things move). They help these smart systems connect with the real world around them.

Today, tiny mechanical devices are in many products you might use. They are in car airbags, inkjet printers, blood pressure monitors, and even big projection screens. It looks like these tiny devices will soon be as common as electronic chips. The technology keeps getting smaller, too, with some parts now less than 20 nanometres!

Micro Electro Mechanical Systems (MEMS)

The term MEMS was created in the 1980s. It describes new, complex mechanical systems built on a chip. These can include tiny electric motors, gears, and other moving parts.

Today, MEMS usually refers to any tiny device with a mechanical job. It must also be made in a batch process, meaning many are made at once. For example, a group of tiny gears made on a microchip would be a MEMS device. But a small watch part made one by one would not be.

In Europe, people often use the term MST, which stands for Micro System Technology. In Japan, they simply call them "micromachines." These names are very similar and are often used to mean the same thing.

There are many ways to make MEMS devices. Some methods create simple shapes, while others can make more complex 3D structures. For example, a company making accelerometers for car airbags needs a very different design and process than one making an accelerometer for navigation. Changing from an accelerometer to a gyroscope (another type of sensor) would require even bigger changes.

MEMS technology is very exciting because it can be used in so many important ways. It offers performance and reliability that were impossible before. In a world where everything needs to be smaller, faster, and cheaper, MEMS offers a great solution.

MEMS has already changed things like car sensors and inkjet printers. The MEMS industry is already worth billions of dollars. It is expected to grow very fast and become one of the biggest industries of the 21st century.

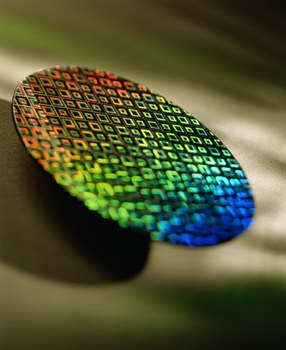

Microtechnology is often built using a process called photolithography. This is like a super tiny printing method. Light waves shine through a mask onto a surface. This light hardens a special chemical film. The soft parts of the film that weren't exposed to light are then washed away. Finally, acid is used to etch away the material that isn't protected by the hardened film.

The most famous success of microtechnology is the integrated circuit, which is the "brain" of almost all electronics. It has also been used to build tiny machines called micromachinery. In the 1980s, as scientists tried to make microtechnology even smaller, nanotechnology was born. This field creates materials and structures that are 1 to 100 nanometres in size.

What Can Be Built at the Microscopic Level?

Here are some things that have been built on a scale of 1 micrometre using photolithography:

* wires * resistors * transistors * thermionic valves * diodes * sensors * capacitors

* electric motors * gears * levers * bearings * hinges

- Fluidics (devices that control liquids or gases):

* valves * channels * pumps * turbines

See also

In Spanish: Microtecnología para niños

In Spanish: Microtecnología para niños