Mint (facility) facts for kids

A mint is a special factory where coins are made to be used as money.

The story of mints is closely linked to the story of coins. Long ago, coins were made by hand, either by hammering metal or pouring it into molds. Only a few hundred or thousand coins could be made at a time. Today, modern mints use machines to make billions of coins. They create many coin dies (the tools that stamp the coin designs) and turn planchets (blank metal discs) into finished coins.

When making lots of coins, the cost of making them is important. For example, the United States Mint spends much less than 25 cents to make a quarter coin. The difference between the coin's value and how much it costs to make helps pay for the mint. However, sometimes a coin costs more to make than its value. For instance, in 2016, a U.S. penny (worth 1 cent) cost 1.5 cents to produce.

Contents

The History of Coin Mints

The First Coins and Mints

The earliest forms of metal money were not coins. People used unshaped metal, rings, or even weapons as money. This happened for thousands of years in ancient empires like Ancient Egypt, Chaldea, and Assyria. Metals were good for showing wealth because they were valuable, durable, could be divided, and were rare. The best metals for coins include gold, silver, copper, and their mixtures.

The very first mint was probably started in Lydia (an ancient kingdom) around 700 BC. It made coins from gold, silver, and electrum (a natural mix of gold and silver). This idea of making coins under the government's power spread to nearby Ancient Greece. Many Greek city-states then started their own mints. Some of the first Greek mints were on islands like Crete. A mint existed in the ancient city of Cydonia on Crete by at least 500 BC.

Around the same time, coins and mints also appeared in China. From there, they spread to Korea and Japan. The Roman Empire started making coins around 400 BC. Their methods greatly influenced how coins were made in Europe later on.

The word "mint" comes from Rome. In 269 BC, silver coins were made at the temple of Juno Moneta. This goddess became linked to money. Her name was then used for both money and the place where it was made. Roman mints were found all over the Roman Empire. They were sometimes used to spread propaganda. People often learned about a new Roman Emperor when coins with his portrait appeared. Even emperors who ruled for only a short time made sure their image was on a coin. For example, Quietus ruled only a part of the Roman Empire from 260 to 261 AD, but he still issued two coins with his picture.

Early Ways of Making Coins

Ancient coins were made by pouring metal into molds or by hitting metal between engraved dies. The Romans cast their larger copper coins in clay molds. They did this because striking such large pieces of metal was not easy. Today, casting is mostly used only by people making fake coins.

The oldest coins were cast in bullet or cone shapes. They were marked on one side using a die that was hit with a hammer. The blank piece of metal was placed on a small anvil. The die was held in place with tongs. The back side of the coin got a rough mark from the hammer. Later, a square mark was made by the sharp edges of the small anvil or punch. The front of these early coins had detailed pictures, but the back usually just had simple punch marks. The shape and number of these marks changed based on the coin's value and weight. Later, the anvil itself was marked with letters or animal figures. Eventually, the anvil was replaced by a second die for the back of the coin.

The round blanks soon became lens-shaped. The blank metal was made red-hot and then hit between cold dies. One hit was usually not enough. This method was similar to how medals are still made today, except that the blank is now allowed to cool before being hit. Around 300 AD, iron began to be used for dies instead of bronze. Because of this, the practice of hitting hot blanks slowly stopped.

In the Middle Ages, metal bars were cast and then hammered flat on an anvil. Pieces were then cut from these flat sheets with shears. These pieces were then hit between dies and trimmed again. A similar method was used in Ancient Egypt around 300 BC, but it had been forgotten. Square pieces of metal were also cut from cast bars, hammered into round discs, and then struck between dies.

When striking, the bottom die was fixed into a block of wood. The blank metal piece was placed on it by hand. The top die was then put on the blank. It was held in place by a holder with a roll of lead to protect the worker's hand. Heavy blows were then struck with a hammer. An early improvement was a tool like a pair of tongs. The two dies were placed at the end of each leg. This meant the dies did not need to be reset after each blow, making the coins more accurate.

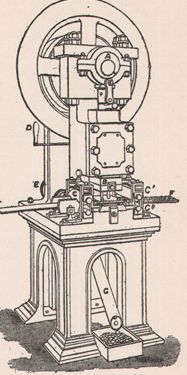

The Screw Press

In many places, a falling weight (like a monkey press) was used to make coins before the screw press. In Birmingham, England, this system became very advanced and was used for a long time. In 1553, the French engineer Aubin Olivier brought in screw presses for striking coins. He also introduced rolls for flattening metal bars and machines for punching out round discs. Eight to twelve men would take turns every 15 minutes to move the arms that drove the screw, which struck the coins. Later, horses, mules, or water power drove the rolls.

King Henry II faced resistance from coin makers, so this new process was mostly stopped in 1585. It was only used for small coins, medals, and tokens. The system was brought back to France by Jean Varin in 1640, and making coins by hammering was forbidden in 1645. In England, the new machines were tried in London in 1561 but soon abandoned. They were finally adopted in 1662, though the old hammered coins stayed in use until 1696.

Modern Coin Making

Modern industrial methods and steam-power were first used in coin making by Matthew Boulton in Birmingham in 1788. By 1786, two-thirds of the coins in Britain were fake. The Royal Mint (Britain's official mint) closed down, making the problem worse. Matthew Boulton, an industrialist, started looking into making coins in the mid-1780s. This was an extension of the small metal products he already made in his factory. In 1788, he set up a mint as part of his factory.

He invented a steam-driven screw press in the same year. His original machines were still used at the Royal Mint almost a century later, until 1881. This press worked by using atmospheric pressure on a piston. The piston was connected to a vacuum chamber from which air had been pumped out by steam power.

Boulton installed eight of these advanced steam-driven presses in his factory. Each one could strike between 70 and 84 coins per minute. His company had trouble getting a license to make British coins at first. However, they soon made coins for the British East India Company, Sierra Leone, and Russia. They also produced high-quality planchets (blank coins) for other national mints to strike. The company sent over 20 million blanks to Philadelphia for the United States Mint. The Mint Director, Elias Boudinot, said they were "perfect and beautifully polished."

These were the first truly modern coins. Making coins in large numbers with steam-powered machines in factories meant that coins could have standard sizes, uniform weight, and be perfectly round. No counterfeiter at the time could hope to achieve this. Boulton also created special ways to make it even harder for counterfeiters. The coins, designed by Heinrich Küchler, had a raised rim with sunken letters and numbers.

The advanced technology of the Soho Mint gained a lot of attention. Rivals tried to steal his ideas, and some even tried to get the government to shut down Boulton's mint. Boulton finally won a contract from the Royal Mint on March 3, 1797. This happened after a national financial crisis when the Bank of England stopped exchanging its paper money for gold. Boulton's twopenny coins were exactly one and a half inches across. Sixteen pennies lined up would reach two feet.

Between 1817 and 1830, the German engineer Dietrich "Diedrich" Uhlhorn invented the Presse Monétaire, a lever coin press. This became known as the Uhlhorn Press. His steam-driven press made him famous around the world. Over 500 units were sold by 1840. The advanced design of the Uhlhorn press worked very well. Because of it, the use of the screw press for making regular coins slowly ended.

This new technology was used at the Birmingham Mint, which was the largest private mint in the world for much of the 1800s. It was further improved by Taylor and Challen, who began supplying complete press room equipment to national mints worldwide, such as the Sydney Mint in Australia. By the early 1900s, mints were using electrical power to run their machines. This was better because each machine could be run separately without needing large, heavy shafts.

Famous Mints Around the World

- Austrian Mint – Started in 1397, it makes the Vienna Philharmonic gold coins.

- Barcelona Mint – Very old, it made gold coins called "mancusos" in 1067.

- Birmingham Mint (United Kingdom)

- Boston mint (Massachusetts Bay Colony)

- Bundesdruckerei (Germany)

- Casa da Moeda do Brasil (Brazil)

- Casa da Moeda de Portugal (Portugal)

- Central Mint (Taiwan)

- Currency Centre (Ireland)

- Dahlonega Mint (United States of America)

- Fábrica Nacional de Moneda y Timbre (Spain)

- Franklin Mint (United States of America)

- India Government Mint

- Printer Institute and State Mint (Italy) – This was the first mint to make bi-metallic coins (coins made of two different metals) in recent times.

- Japan Mint

- Joachimsthal Royal Mint (Czech Republic)

- Kremnica mint (Slovak Republic)

- Casa de Moneda de México – Started in 1535, it is the oldest mint in the Americas.

- La Moneda Palace (Chile)

- Monnaie de Navarre (Kingdom of Navarre) – Started in 1351.

- Monnaie de Paris (France)

- Perth Mint (Australia)

- Philadelphia Mint (United States)

- Royal Australian Mint

- Royal Canadian Mint

- Royal Dutch Mint

- Royal Mint (United Kingdom)

- Singapore Mint

- Saint Petersburg Mint (Russia)

- South African Mint

- Soho Mint (United Kingdom)

- Swissmint (Switzerland)

- Sydney Mint (Australia)

- United States Mint

- Venice Mint (Republic of Venice) – Started in 1536.

See also

In Spanish: Casa de moneda para niños

In Spanish: Casa de moneda para niños

- Branch mint

- Bullion coin

- German inventors and discoverers

- List of mints

- Master of the Mint

- Mint-made errors

- Münzmeister

| Madam C. J. Walker |

| Janet Emerson Bashen |

| Annie Turnbo Malone |

| Maggie L. Walker |