Underfloor heating facts for kids

Underfloor heating and cooling is a way to heat or cool buildings from the floor up. It's a type of central heating and cooling system. This system helps control the temperature inside for a comfortable feeling. It uses either water-filled pipes (called hydronic systems) or electric wires. These are hidden inside the floor. Heat moves from the floor into the room in three ways: by touching, by radiation (like sun warmth), and by convection (air movement). People have used floor heating for thousands of years, even back in ancient times!

Contents

History of Floor Heating

People have been warming their floors for a very long time, even before recorded history. Archeologists have found old homes in Asia and Alaska where people used smoke from fires to heat stones under their floors. This hot smoke warmed the floor, and the heat then spread into their homes. Over time, these early ideas led to the modern systems we have today, which use pipes with fluid or electric cables.

Here's a quick look at how floor heating has changed over the years:

- Around 5,000 BC: Early signs of "baked floors" were found in places like Manchuria and Korea. These were like early versions of "heated floors" called kang and ondol.

- Around 3,000 BC: In Korea, a fire hearth was used for both cooking and heating.

- Around 1,000 BC: Similar ondol-style systems were used in Alaska and North Korea.

- Around 1,000 BC: Some homes had two hearths. One in the middle was for heating, and another on the edge was for cooking. The cooking hearth later became part of the traditional Korean ondol system.

- Around 500 BC: The Romans invented hypocausts. These systems used hot air under floors and behind walls to heat large buildings.

- Around 200 BC: In Korea, the central hearth became more advanced, and the cooking hearth developed into the "budumak" kitchen range.

- Around 50 BC: China, Korea, and the Roman Empire were all using different forms of floor heating.

- Around 500 AD: Floor heating continued in Asia. But in Europe, people mostly switched to open fires. Some stories mention early cooling systems in the Middle East using snow in wall spaces.

- Around 700 AD: More advanced ondol systems were found in palaces in Korea. Countries around the Mediterranean (like Iran and Turkey) used hypocaust-like heating in baths and homes. They also used heat from cooking stoves (like tandoors) to warm floors.

- Around 1000 AD: Ondol systems in Asia became even better. In Korea, the fire furnace was moved outside, and the whole room floor was heated. In Europe, chimneys became common for fireplaces.

- Around 1300 AD: Hypocaust systems were used to heat monasteries in Poland and the Teutonic Malbork Castle.

- Around 1400 AD: Turkish Baths in the Ottoman Empire used hypocaust-style heating.

- Around 1500 AD: People in Europe started caring more about comfort in buildings. China and Korea widely adopted floor heating.

- Around 1600 AD: In France, heated flues (pipes for smoke) were used in floors and walls of greenhouses.

- Around 1700 AD: Benjamin Franklin studied heating systems in France and Asia. This helped him develop the Franklin stove. Steam pipes were used for heating in France.

- Around 1800 AD: Modern water heaters and pipe systems began to develop in Europe. Small pipes were used for heating in the John Soane house.

- 1864: Ondol-like systems were used in American Civil War hospitals. The Reichstag building in Germany used its structure to help with heating and cooling.

- 1899: A German scientist found a waxy substance that was later named polymethylene. This was the very beginning of the plastic pipes used today.

- 1904: Liverpool Cathedral in England was heated using hypocaust ideas.

- 1905: Architect Frank Lloyd Wright visited Japan and later used radiant heating in his designs.

- 1907: A patent for "panel warming" using small pipes was granted in England.

- 1930: Oscar Faber in England used water pipes to heat and cool large buildings.

- 1933: An explosion at a lab in England accidentally created a wax-like substance. This later became polyethylene, which is used for PEX pipes.

- 1937: Frank Lloyd Wright designed the Herbert Jacobs house, which had radiant heating.

- 1945: After World War II, many homes in America were built with water-based radiant heating using copper pipes.

- 1950: The Korean War led to a shortage of wood for ondol, so people started using coal. In California, thousands of homes with radiant heating were built.

- 1951: Early tests of plastic pipes (polyethylene, vinyl) for radiant floor heating began in America.

- 1965: Thomas Engel patented a way to make polyethylene stronger by "cross-linking" its molecules (PEx-A).

- 1970: As buildings in Korea grew taller, coal-based ondol systems caused problems. They were replaced by central water-based heating.

- 1980: The first standards for floor heating were created in Europe. Water-based ondol became common in Korean homes.

- 1985: Floor heating became a standard heating system in homes in Central Europe and Nordic countries. It also started to be used more in other buildings.

- 1995: Floor cooling and systems that use the building's structure for heating and cooling (TABS) became popular.

- 2000: Embedded radiant cooling became standard in Central Europe. Many parts of the world started using radiant systems because they work well with lower heating temperatures and higher cooling temperatures.

- 2010: The 71-story Pearl River Tower in China, which uses radiant heating and cooling, was completed.

How Underfloor Heating Works

Modern underfloor heating systems use two main ways to heat the floor:

- Electric systems: These use special electric wires or mats.

- Hydronic systems: These use fluid (usually water) flowing through pipes.

Both types can heat a whole building or just a small area for extra comfort. Some systems let you heat only certain rooms, saving energy. Electric systems only heat, but hydronic systems can also cool a space.

Underfloor heating is also used for other things, like melting snow on driveways, warming sports fields, or preventing ice in freezers. Different systems are available for different types of floors.

The heating elements or pipes can be set into a concrete floor slab (called a "wet system"). Or they can be placed under the floor covering or attached directly to a wood subfloor (these are "dry systems").

Some large buildings use the floor's "thermal mass" (its ability to store heat). They heat or cool the floor during off-peak hours when electricity is cheaper. Then, during the day, the floor slowly releases or absorbs heat, keeping the room comfortable. These are called thermally activated building systems (TABS).

You might hear these systems called "radiant heating" or "radiant cooling". This is because a lot of the comfort comes from heat radiating from (or to) the floor.

Hydronic Systems

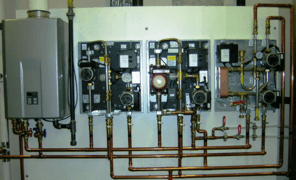

Hydronic systems use water, or a mix of water and anti-freeze, to carry heat. This fluid flows in a "closed loop" between the floor pipes and a boiler (heater).

The pipes used for hydronic systems are usually made from polyethylene, like PEX or PERT. Older materials like copper or steel are still used sometimes.

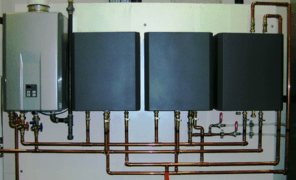

Hydronic systems need skilled people to design and install them. They work with boilers, pumps, and controls for water pressure and temperature. Modern factory-made units can make these systems simpler to set up.

Hydronic systems can use one or more energy sources to save money:

- Boilers (heaters): These can be powered by Natural gas, Propane, Coal, oil, Electricity, solar thermal energy, wood, or other biomass.

- Heat pumps and chillers: These can be powered by Electricity, Natural gas, or geothermal energy (heat from the Earth).

Electric Systems

Electric systems are only used for heating. They use flexible heating elements like cables, mats, or carbon films. Because they are thin, they can be put directly under floor finishes.

Electric systems can use cheaper electricity during off-peak hours. They are often used as carpet heaters, under-rug heaters, or for warming floors under tiles or wood. While large electric systems need skilled designers, smaller floor warming systems are simpler to install. Electric systems have fewer parts and are easier to set up than hydronic ones.

Benefits of Underfloor Heating

Comfort and Temperature

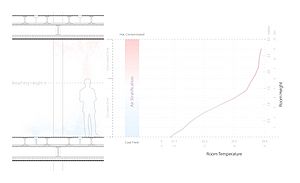

Underfloor heating makes a room feel comfortable. This comfort comes from the floor's temperature and how it affects the air and heat around you. Studies show that people at rest lose more than half their body heat through radiation.

Underfloor heating warms the surfaces in a room. This reduces how much heat your body loses, making you feel warm and comfortable. It also warms the air near the floor, which then rises. Underfloor cooling works by absorbing heat, making surfaces cool. This helps your body lose heat, making you feel cool. Floor heating and cooling systems can fix problems like cold or warm spots on the floor.

Better Air Quality

Underfloor heating can improve the air quality inside your home. It allows you to use "cold" flooring materials like tile or concrete. These materials usually release very few harmful chemicals (VOCs) compared to other floor types.

Also, floor heating helps control moisture. This creates conditions that are less friendly for mold, bacteria, viruses, and dust mites to grow. By taking care of the heating, the system can also better filter and dehumidify the air. This helps reduce airborne pollutants. Doctors have noted the benefits of floor heating, especially for people with allergies.

Energy Efficiency

Underfloor heating systems can be very energy efficient. When used in well-built homes, they can heat with lower temperatures and cool with higher temperatures. This makes them work well with geothermal and solar thermal systems, which use natural energy.

Using these renewable energy sources means less burning of fuels and fewer greenhouse gases from boilers or power plants. This helps save non-renewable resources for the future.

Safety and Health

Low-temperature underfloor heating is hidden in the floor. This means it doesn't take up wall space and doesn't create burn hazards. It also reduces the risk of tripping and falling. This is a good feature for places like healthcare facilities, especially for older people.

Heated floors can also help wet floors dry faster after cleaning or spills. Plus, hydronic systems (with fluid-filled pipes) are safe for heating and cooling places where explosions could happen. This is because the heating equipment can be located far away from the dangerous area.

However, some electric underfloor heating systems can create low-frequency magnetic fields. Older single-wire systems create more than modern two-wire systems. Some research suggests these magnetic fields might possibly be linked to cancer.

Here are some famous buildings that use underfloor heating:

- 41 Cooper Square, United States

- Akron Art Museum, United States

- BMW Welt, Germany

- California Academy of Science, United States

- Copenhagen Opera House, Denmark

- Ewha Womans University, South Korea

- Hearst Tower, New York City, United States

- Manitoba Hydro Place, Canada

- National Renewable Energy Laboratory Research Support Facility, United States

- Pearl River Tower, China

- Post Tower, Germany

- Suvarnabhumi Airport, Bangkok

See also

In Spanish: Suelo radiante para niños

In Spanish: Suelo radiante para niños

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |